Applications of Advanced Ceramics in the Chemical, Plastics & Rubber

Advanced ceramics have emerged as indispensable materials across the chemical, plastics, and rubber sectors, thanks to their exceptional corrosion resistance, wear resistance, and high-temperature stability. From reactor linings in petrochemical plants to ceramic-coated rollers in polymer processing lines, these engineered materials optimize equipment longevity, improve process efficiency, and enable green manufacturing.

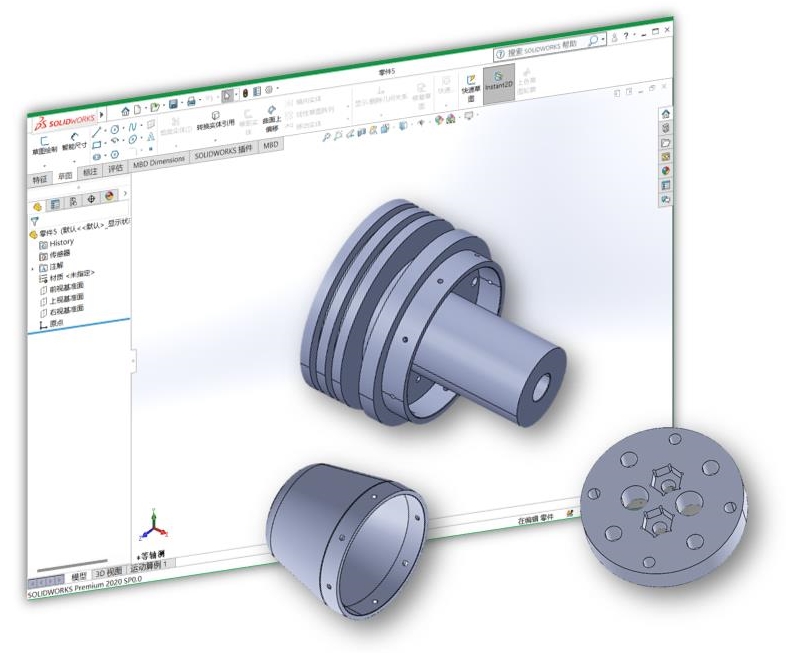

Great Ceramic provides precision-engineered ceramic components specifically designed for the chemical, plastics, and rubber industries. These technical ceramics offer unmatched wear resistance, thermal stability, chemical inertness, and electrical insulation, making them essential for upstream, midstream, and downstream applications.

Why Use Advanced Ceramics?

Advanced ceramics are engineered materials characterized by high purity, controlled microstructures, and superior properties compared to traditional ceramics. Key features include:

These attributes make advanced ceramics indispensable in roles where metals or polymers fail—particularly in corrosive, abrasive, or high‐temperature environments.

benefit:

Key Applications

In the Chemical Industry

in the Plastics Industry

in the Rubber Industry

Most Common Ceramic Materials Used

At Great Ceramic, we help our customers in the chemical, plastics, and rubber industries achieve unprecedented levels of performance, reliability, and sustainability by utilizing advanced ceramics such as alumina (Al₂O₃), silicon carbide (SiC), silicon nitride (Si₃N₄), and zirconium oxide toughened alumina (ZTA20).

| Ceramic Material | Properties & Benefits | Typical Applications |

|---|---|---|

| Alumina (Al₂O₃) | High hardness, good chemical resistance, cost-effective | Seals, bushings, guides, valves |

| Zirconia (ZrO₂) | Tough, wear-resistant, corrosion-resistant | Pump shafts, plungers, grinding media |

| Silicon Carbide (SiC) | Extreme hardness, thermal shock resistance, excellent corrosion resistance | Nozzles, reactor linings, extrusion tools |

| Silicon Nitride (Si₃N₄) | Lightweight, high strength, thermal shock resistance | Bearings, mixers, high-temp valve components |

| Aluminum Nitride (AlN) | High thermal conductivity, electrical insulation | High-temp electronics, heaters, process monitoring devices |

| Boron Nitride (BN) | Chemically inert, excellent lubricity and insulation | Lubricating coatings, insulators, crucibles |

| ZTA (Zirconia Toughened Alumina) | Balanced toughness and hardness | Die inserts, guides, wear plates |

| MGC (Machinable Glass Ceramic) | Easily machinable, good thermal/electrical insulation | Insulating components, spacers, custom lab parts |

Great Ceramic's Capabilities

At Great Ceramic, we provide custom precision ceramic parts tailored for demanding chemical and plastic processing environments. From zirconia plungers to alumina nozzles and silicon carbide wear-resistant liners, our materials and manufacturing capabilities ensure longevity, precision, and performance.

Relevant Products

Frequently Asked Questions (FAQ)

Why Choose Great Ceramic for Applications?

Explore our Precision Ceramic Machining Solutions for high-performance chemical, plastics, and rubber components.