Ceramic Metallization & Metal Brazing Solution

At Great Ceramic, we provide professional ceramic surface metallization and brazing services for demanding industries such as aerospace, power electronics, vacuum systems, medical devices, and semiconductor manufacturing.

Combining deep expertise in technical ceramics, precision brazing, and hermetic ceramic-to-metal seal design, we help customers create reliable, high-performance assemblies that perform in extreme environments.

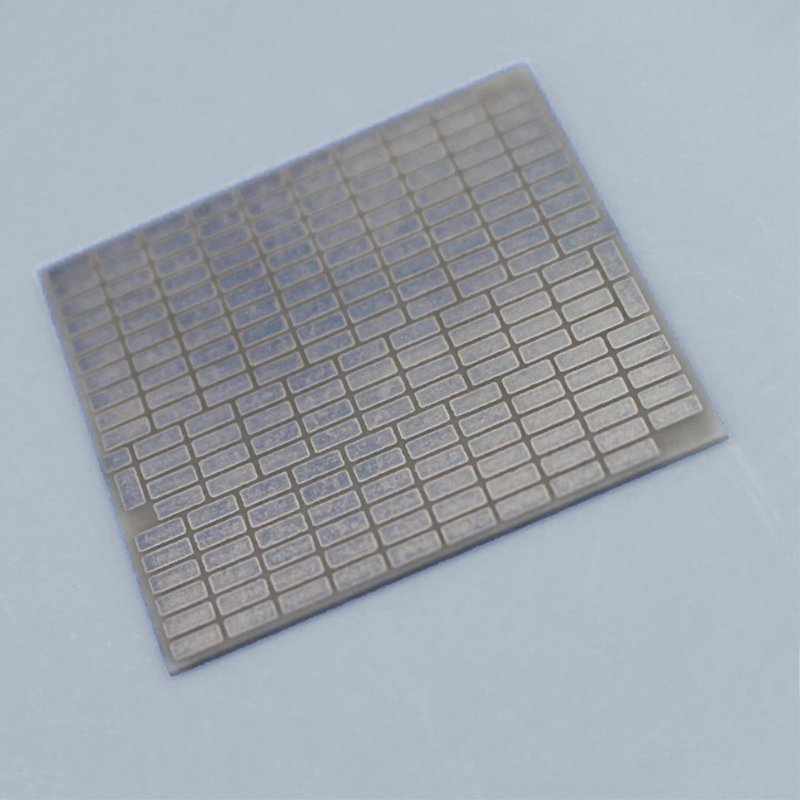

Ceramic metallization is the process of applying a conductive metal layer onto the surface of ceramic components, enabling them to be soldered, brazed, or electrically connected to metals. This process is essential for producing ceramic to metal seals in vacuum systems, high-frequency devices, and electrical insulation assemblies.

At Great Ceramic, we offer multiple metallization options:

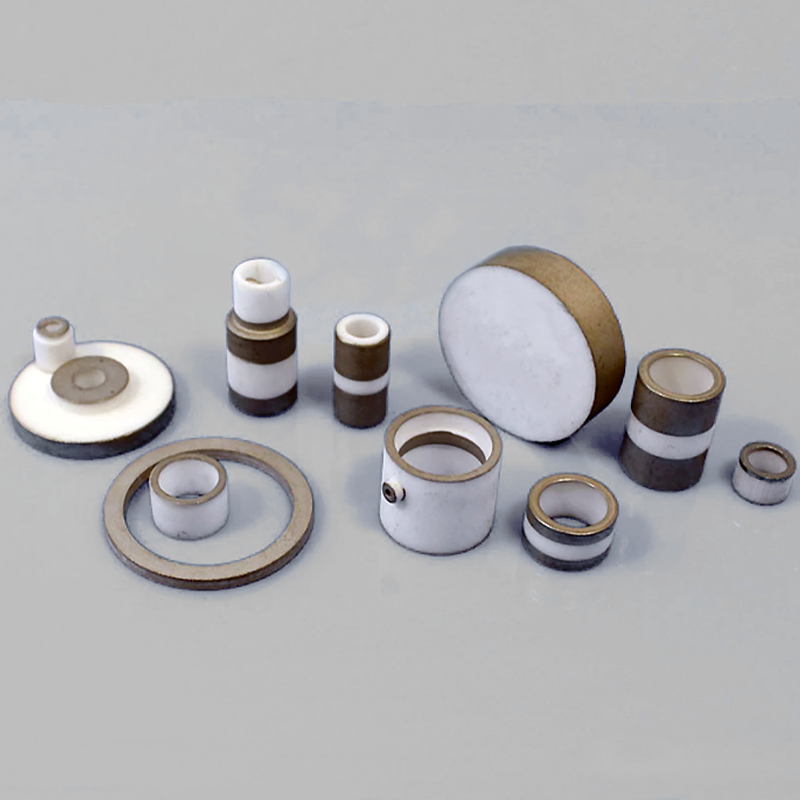

Metallized Ceramic Components We Provide

Metallized Ceramic Insulator

Suitable for RF windows, laser systems, and sensor housings

Vacuum Ceramic Component

Tailored to specific mechanical, electrical, or environmental requirements

Metallized Ceramic Tubes

Used in electron tubes, thermocouples, and insulation

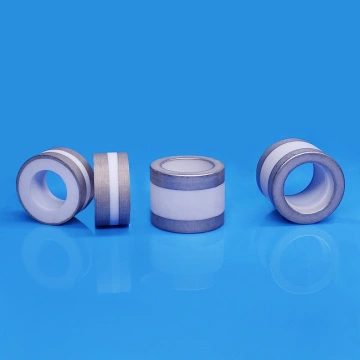

Metallized Ceramic Ring

Hermetic feedthroughs for vacuum and power devices

All metallized layers are inspected for adhesion, thickness, continuity, and surface quality. Plated layers are tested for solderability and corrosion resistance.

Once metallized, ceramic parts are brazed to metals like Kovar, titanium, or stainless steel using high-temperature brazing techniques. This creates ceramic-to-metal assemblies with superior gas-tightness and mechanical reliability.

Great Ceramic can provide technical ceramic brazed components to meet the specific requirements of customers. Many of the parts we provide are complex, designed to strict specifications or used in particularly demanding critical applications.

Ceramic Brazing Features

The product adopts Kovar material or oxygen-free copper with a coefficient of linear expansion similar to that of ceramics to achieve ceramic-to-metal sealing through brazing. Realize the airtight connection of ceramic parts and metal structural parts. This ceramic-metal sealing structure has the characteristics of high sealing strength, good air tightness, and high reliability.

Ceramic Brazing & Sealing Applications

Used in vacuum switch tubes for electric power and electronics, various klystrons, traveling wave tubes, microwave tubes, magnetrons, thyratrons, triggers, vacuum gauges, microwave night vision devices and other related vacuum insulation industries. The general use temperature does not exceed 700°C.

Applications of Metallized Ceramics & Brazed Assemblies

Our metallized ceramics and brazed components are widely used across industries for critical tasks that require hermeticity, electrical insulation, thermal conductivity, and mechanical strength.