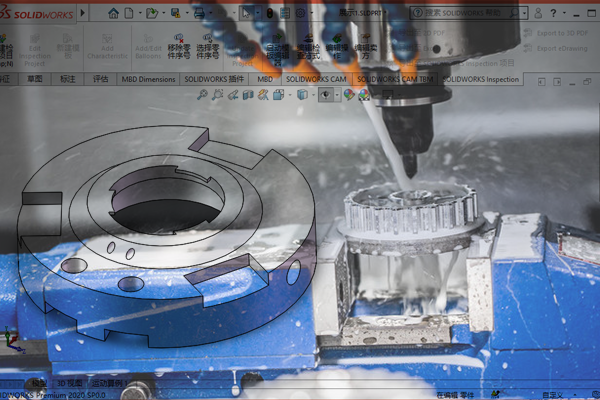

Ceramic Machining & Grinding

Machining most precision (Advanced) ceramics is a difficult task due to its incredible hardness and high brittleness. In order to continuously produce high quality ceramic parts at reasonable cost, you must have the right machining tools, in-depth material knowledge and correct ceramic manufacturing design. Great Ceramic has many years of experience in developing high quality precision (Advanced) ceramic parts. We use our experienced team and in-depth knowledge of ceramic materials to create the best precision (Advanced) ceramic products for customers at competitive prices. Based on our rich ceramic knowledge and years of practical experience in ceramic application and ceramic production and processing, we can provide our customers with:

- High flexibility – we can often create products using a variety of different technologies to give our customers more choices to meet their needs.

- Competitive pricing – with customer satisfaction as the core value, Great Ceramic strives to achieve high efficiency and save costs for customers.

- High quality products – we focus on the precision (Advanced) ceramic industry and strive for it as a reliable ceramic supplier – we continue to invest in our company to ensure that our customers get the highest quality parts and services.

Ceramic Machining

Great Ceramic focuses on the precision (Advanced) ceramic industry and has rich experience in milling, grinding and polishing of precision (Advanced) ceramics, as well as firing ceramics, which enables us to provide a variety of technical ceramic services, including:

- Ceramic milling and grinding

- Ceramic sintering

- Metallization of ceramic surface

- Glaze treatment of ceramic surface

- Product surface polishing

- Other

Machining Tolerances

- The general tolerance of grinding is ± 0.02mm, the most precise is ± 0.005mm, and the surface roughness can reach Ra0.02um;

- The general tolerance of rotary machining is ± 0.02mm, the most precise is ± 0.005mm, and the surface roughness can reach Ra0.02um;

- The general tolerance of centerless grinding is ± 0.01mm, the most precise is ± 0.002mm, and the surface roughness can reach Ra0.02um;

- The general tolerance of milling is ± 0.05mm, the most precise is ± 0.01mm, and the surface roughness can reach Ra0.4um;

- The general tolerance of laser processing is ± 0.05mm, the most precise is ± 0.01mm, and the edge is slightly rough;

- The general tolerance of honing inner hole is ± 0.005mm, the most precise is ± 0.003mm, and the surface roughness can reach Ra0.02um;

- The general error of product size error of mould forming is 1% of the size and 0.5% of the dimension at the most precise time. Sometimes, there may be some differences in this data because ceramic sintering is a more complex process;

- When the ceramic rolling polishing is the best, the mirror effect can be achieved, and the highest roughness can reach Ra0.02um.

All tolerances can be improved according to the size, shape and geometry of precision (Advanced) ceramic parts. Great ceramics is committed to ensuring that we only provide the highest quality parts that meet or exceed customer specifications. Great ceramics has accumulated many years of experience in the pursuit of the development of excellent advanced technology ceramic parts, and has continuously applied these knowledge. In fact, we have provided customized services for many companies and organizations for precision (Advanced) ceramics. Contact us to find out what we can do for you.