Boron Nitride (BN)

Boron nitride (BN) is a remarkable advanced ceramic material whose unique properties make it stand out in numerous demanding applications. It shares a similar hexagonal crystal structure with graphite, which is why it's also known as hexagonal boron nitride (hBN). This unique boron nitride structure gives it an amazing set of characteristics, making it an ideal choice for high-temperature, high-pressure, insulation, and lubrication applications.

Our boron nitride ceramic is meticulously crafted using precision processes to deliver exceptional comprehensive performance. From boron nitride powder to the final boron nitride products, we are dedicated to providing high-quality solutions that meet our customers' specific needs. h boron nitride is the most common and widely used form, with the chemical formula BN (boron nitride formula).

Skip to

Advantages | Applications | Material Grades | Properties | Cases | Machining | FAQs | Related

Key Advantages of Boron Nitride

By choosing boron nitride material, you gain a series of unparalleled advantages:

Industry Applications

Boron nitride (BN) ceramics, due to their high-temperature stability, chemical inertness, electrical insulation, and excellent layer-to-layer thermal conductivity, are widely used in the electronics and semiconductor fields (used as thermal interface materials, thermally conductive insulating substrates, and PBN crucibles and supports for wafer/thin film processing), metallurgy and materials processing (used as crucibles, melting chambers, liquid metal conveying devices, and corrosion-resistant linings), high-temperature and vacuum equipment (used as heat shields, infrared windows, and thermal shock components), and mechanical lubrication and sealing (utilizing the solid lubrication and low friction properties of h-BN). While maintaining electrical insulation while improving thermal conductivity, they play an important role in industries such as aerospace, semiconductor manufacturing, optoelectronic devices, precision ceramic processing, and high-temperature chemical engineering.

Available grades of Boron Nitride material

Great Ceramic offers multiple BN product grades and formats to suit application demands:

Hexagonal Boron Nitride (Standard)

Boron nitride ceramic (standard) is an advanced ceramic material with excellent high-temperature stability, high thermal conductivity, and self-lubricating properties. With a BN purity of ≥99%, it ranks among the mainstream performance grades in the boron nitride family and offers a high cost-performance ratio. While maintaining excellent electrical insulation, it exhibits good chemical inertness and thermal shock resistance, making it suitable for extreme operating conditions such as high temperature, high vacuum, and corrosion resistance.

Compared to other engineering ceramics (such as alumina and zirconia), boron nitride combines a low coefficient of friction with excellent processability, enabling long-term stable operation in high-temperature environments and enabling precision machining. It is suitable for the manufacture of critical components requiring high-temperature insulation and lubrication.

Key Features

Typical Applications

Production and Processing

Conventional boron nitride ceramics are produced through chemical synthesis using boron trioxide (B₂O₃) and ammonia (NH₃) or urea as the primary raw materials. Boron nitride powder is obtained through chemical synthesis. Depending on the application, forming methods such as dry pressing, isostatic pressing, and extrusion can be used.

Sintering is typically performed using hot pressing (1900–2100°C, nitrogen or inert atmosphere). A small amount of oxide is sometimes added as a sintering aid to increase density.

The finished product can be directly subjected to finishing processes such as turning, milling, and drilling. The surface can also be coated with ceramics such as SiC and AlN to enhance mechanical strength and oxidation resistance.

Boron Nitride Ceramics (High Purity)

High-purity boron nitride (BN) ceramics are ultra-high-purity (BN content ≥ 99.5%) advanced ceramic materials with exceptional thermal stability, electrical insulation, self-lubricity, and chemical inertness. By strictly controlling impurity levels, the material's thermal conductivity and insulation reliability are significantly enhanced. They are particularly suitable for extreme operating conditions such as high temperature, high vacuum, and severe corrosion, as well as for the semiconductor, aerospace, and high-end metallurgy industries, which demand stringent purity standards.

Compared to conventional boron nitride ceramics, high-purity grades offer superior electrical, thermal, and chemical stability, significantly reducing the risk of impurity-induced failure, extending the life of critical components, and maintaining stable operation in extreme environments.

Key Features

Typical Applications

Production and Processing

High-purity boron nitride ceramics are produced using ultra-high-purity h-BN powder through a hot pressing process. The sintered high-purity BN has a moderate hardness and can be precision-machined through turning, milling, drilling, and other processes.

Pyrolytic Boron Nitride Ceramics (PBN)

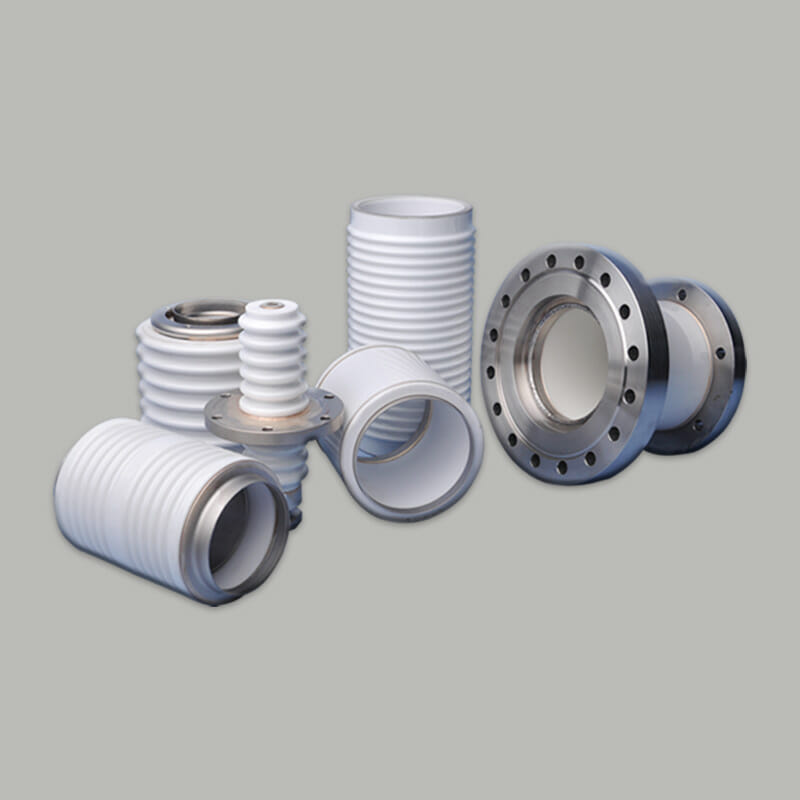

Pyrolytic Boron Nitride (PBN) ceramics are high-purity (≥99.99%) hexagonal boron nitride materials produced using a chemical vapor deposition (CVD) process. This unique deposition method results in a binder-free, impurity-free material with a dense, uniform microstructure, exceptional purity, and excellent anisotropic properties.

Compared to hot-pressed boron nitride (HPBN), PBN offers higher purity, superior airtightness, and a dense, smooth surface. It can be formed directly into desired shapes during the deposition process, making it particularly suitable for ultra-high vacuum, high-purity material processing, and contamination-sensitive semiconductor manufacturing environments.

Key Features

Typical Applications

Production and Processing

Pyrolytic Boron Nitride Ceramics are produced using the Chemical Vapor Deposition (CVD) process:

- Deposition Materials: Boron trichloride (BCl₃) and ammonia (NH₃)

- Process Conditions: The reaction occurs within a high-temperature graphite mold at 1800–2000°C. BN is deposited molecularly on the mold's inner wall, gradually forming a dense structure.

- Direct Forming: The CVD process allows for direct deposition and molding according to the mold's shape, eliminating the need for sintering and binders, thus preventing secondary contamination.

- Post-Processing: Most PBN parts are ready for immediate use. If adjustments are required, precision machining or surface treatment can be performed.

Composite Boron Nitride Ceramics

Compound Boron Nitride Ceramics are a class of engineering ceramic materials based on a boron nitride (BN) matrix reinforced or modified with other ceramic or metal compounds (such as aluminum oxide (Al₂O₃), aluminum nitride (AlN), silicon carbide (SiC), zirconium oxide (ZrO₂), and boron oxide glass). Their design goal is to significantly enhance mechanical strength, oxidation resistance, wear resistance, and thermal conductivity while maintaining BN's excellent high-temperature insulation, self-lubricity, and chemical inertness.

Compared to pure BN ceramics, composite Boron Nitride exhibits superior high-temperature strength, density, and environmental adaptability, meeting the demanding operating conditions in metallurgy, semiconductors, vacuum coating, and aerospace.

Key Features

Typical Applications

Production and Processing

Raw Material Preparation: Select high-purity BN powder and reinforcement phase powder (such as Al₂O₃, AlN, SiC, ZrO₂), and mix them evenly according to the formula ratio.

Molding Process: Dry pressing, isostatic pressing, or slip casting are commonly used, with different methods selected depending on the complexity of the product.

Sintering methods: Hot pressing (HP), hot isostatic pressing (HIP), or reaction sintering; temperatures typically range from 1700–2000°C in a nitrogen or inert gas atmosphere.

Post-processing: Machining to final shape. Surface coatings (e.g., SiC, Al₂O₃) may be applied as needed to further enhance oxidation and wear resistance.

Key Properties of Boron Nitride

Great Ceramic offers a variety of boron nitride materials for customers to choose from. The following values are typical material properties and may vary depending on product configuration and manufacturing process. For more details, please feel free to contact us.

| Parameter | GCBN-HBN1 | GCBN-HBN2 | GCBN-PBN | GCBN-B | GCBN-C | GCBN-D | GCBN-E | GCBN-S2 | GCBN-S3 |

|---|---|---|---|---|---|---|---|---|---|

| Main Composition | BN ≥ 99%(Standard) | BN ≥ 99.5%(High Purity) | BN ≥ 99.99% | BN + Zr+Al | BN + SiC | BN + ZrO₂ | BN + AlN | BN + Si₃N₄ | BN + Si₃N₄ |

| Density (g/cm³) | 2.0–2.3 | ≥2.0 | 1.95–2.22 | 2.25–2.35 | 2.40–2.50 | 2.80–2.90 | 2.80–2.90 | 2.55–2.65 | 2.75–2.85 |

| Oxygen Content (%) | 0.46 | <0.3 | <0.1 | — | — | — | — | — | — |

| Porosity (%) | 2.6 | <2.0 | Dense | — | — | — | — | — | — |

| Leeb Hardness HL | ≥330 | ≥330 | — | — | — | — | — | — | — |

| 3-Point Bending Strength (MPa) | 38 | 40–50 | 80 | 65 | 85 | 115 | 120 | 220 | 320 |

| Compressive Strength (MPa) | 110–150 | 120–160 | — | 110 | 130 | 225 | 220 | 420 | 480 |

| CTE (×10⁻⁶/K) | 2.0–2.8 | 2.0–2.5 | 2.0 (a) / 2.6 (c) | 2.0 | 2.8 | 3.5 | 2.8 | 2.7 | 2.7 |

| Thermal Conductivity (W/m·K) | 30–50 | 50 | 82.3 (200℃) / 55.3 (900℃) | 30 | 30 | 20 | 80 | 40 | 40 |

| Max Operating Temp (℃) | Air 900 / Vac 2100 / Inert 2300 | Air 900 / Vac 2100 / Inert 2300 | 2000+ | Air 1000 / Vac 1800 / Inert 1800 | Air 1000 / Vac 1800 / Inert 1800 | Air 1000 / Vac 1800 / Inert 1800 | Air 1000 / Vac 1800 / Inert 1800 | Air 1000 / Vac 1800 / Inert 1800 | Air 1000 / Vac 1800 / Inert 1800 |

| Room Temp Resistivity (Ω·cm) | >10¹⁴ | >10¹⁴ | 10¹⁵ | >10¹³ | >10¹² | >10¹² | >10¹³ | >10¹³ | >10¹³ |

| Typical Applications | Powder metallurgy, metal evaporation crucibles, insulators | Semiconductor equipment, high-temp insulation parts | Vacuum coating, semiconductor heaters, insulation components | Powder metallurgy, high-temp supports | Powder metallurgy | Metal casting molds | Powder metallurgy | Powder metallurgy | Powder metallurgy |

boron nitride product application cases

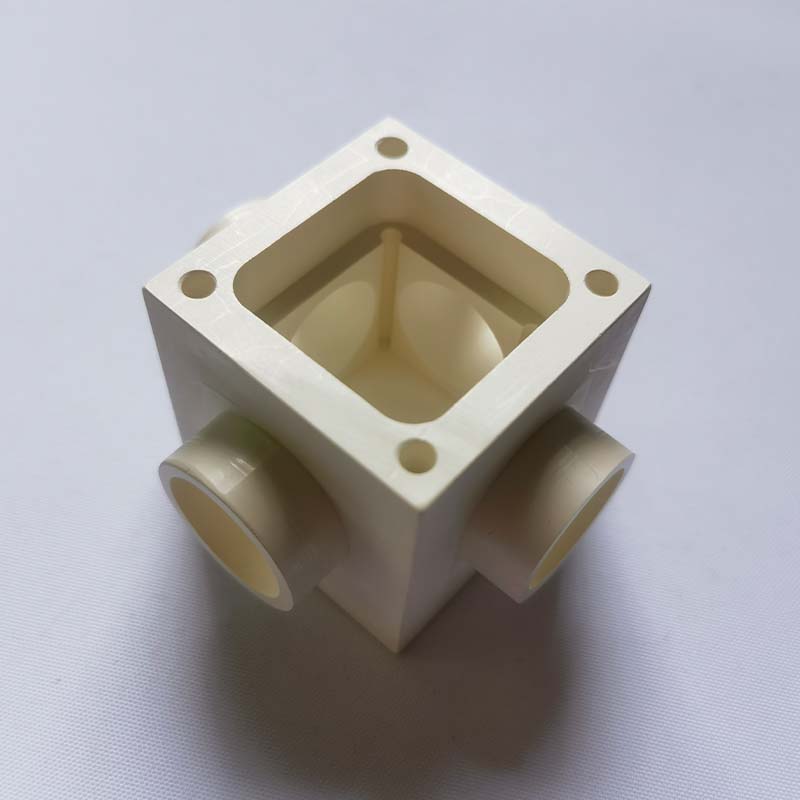

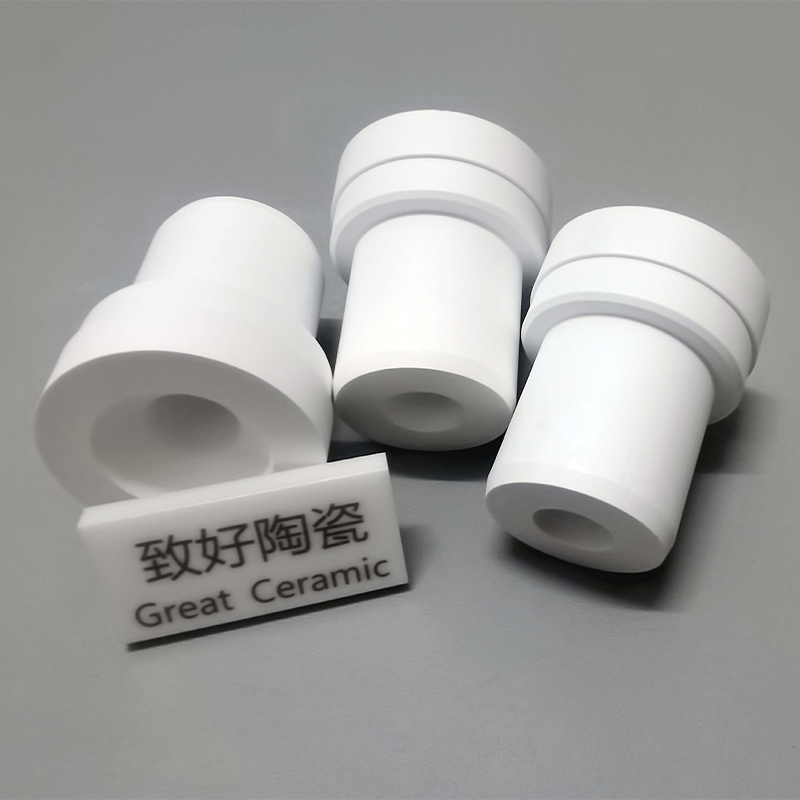

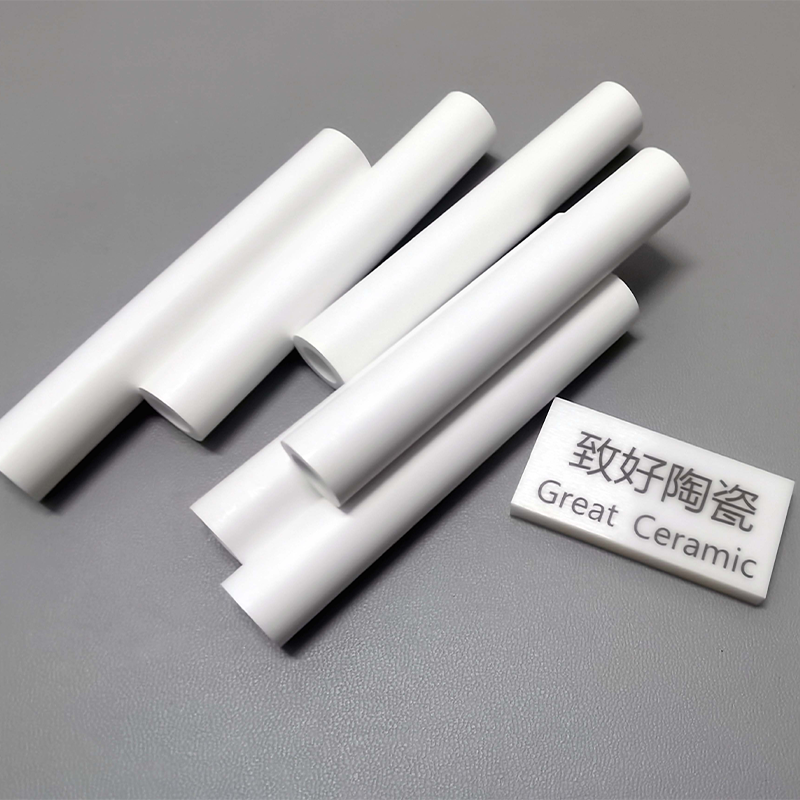

Great Ceramic's boron nitride ceramic products, particularly in the forms of hexagonal boron nitride (h-BN) and pyrolytic boron nitride (PBN), offer exceptional thermal conductivity, excellent electrical insulation, chemical inertness, low hardness for easy processing, and excellent high-temperature stability. These properties make our BN parts suitable for use in a wide range of industries. Common applications for our boron nitride products include:

Precautions for Using Boron Nitride Ceramics

When using boron nitride ceramics, following these precautions can help maximize the performance, stability, and life of boron nitride products in demanding industrial applications.

Boron Nitride Machining

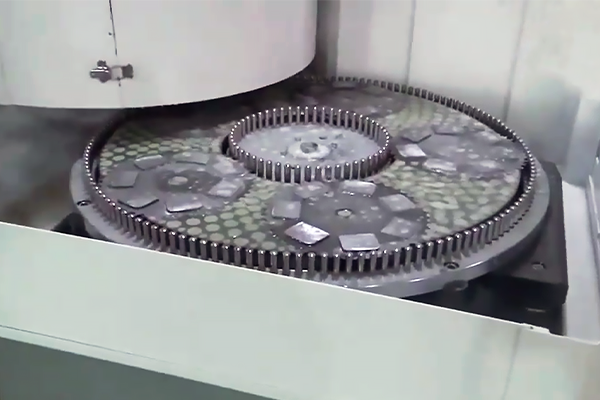

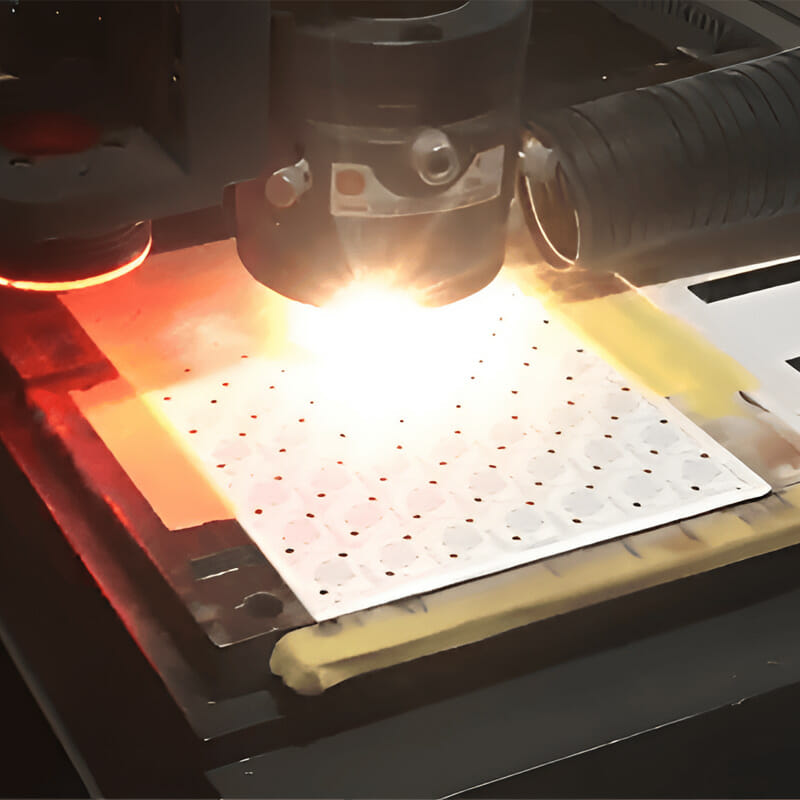

One unique advantage of boron nitride is its relatively low hardness (Mohs ~2 for h-BN), which makes it more machinable than many other ceramics. Standard carbide or high-speed steel tools can be used for h-BN, while harder BN composites may require diamond grinding, CNC machining, laser cutting, or ultrasonic machining to ensure accuracy and surface finish.

With a complete range of advanced machining equipment and extensive technical expertise, Great Ceramic provides end-to-end solutions—from material selection and design optimization to precision machining and assembly—ensuring high-quality, high-performance boron nitride ceramic products that meet the most demanding application requirements.