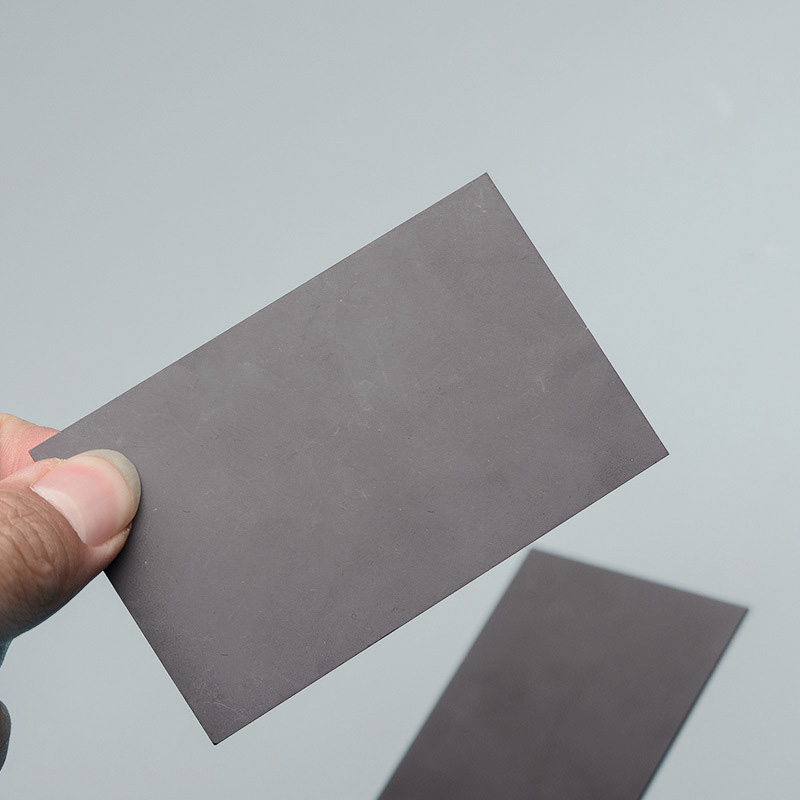

Black Alumina Ceramic Substrate

Black alumina ceramics, like traditional alumina ceramics, have excellent properties such as good insulation performance, small expansion coefficient, high thermal conductivity, high mechanical strength, good light shielding, wear resistance, and low dielectric loss. These substrates are widely used in semiconductor integrated circuits and electronic product packaging due to their high photosensitivity and strong light-shielding properties.

Black Aluminum Oxide Ceramic Machining

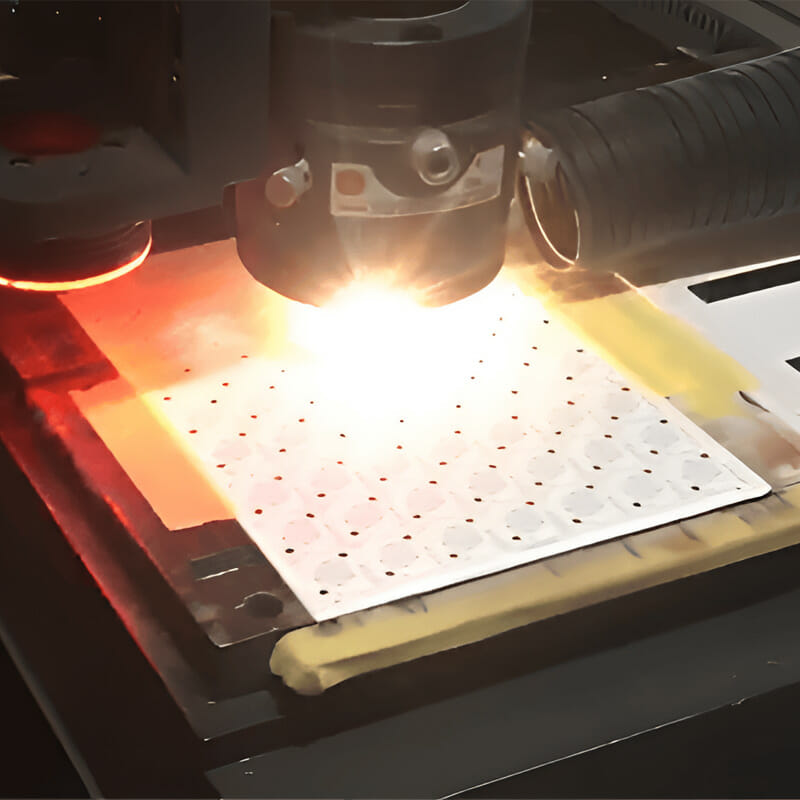

Great Ceramic provides a variety of alumina ceramic substrates of different purity, which have the characteristics of superior comprehensive performance, good thickness uniformity, and high density. Various shapes can be customized according to customer needs through machining, grinding, polishing, laser cutting and other processes, and surface metallization can be performed.

Properties of Black Alumina Ceramic

Black alumina ceramic substrates offer several advantages over traditional alumina ceramics, such as:

- Strong shading properties

- Improved electrical insulation

- Better thermal conductivity

- Enhanced mechanical strength

- Higher chemical durability

- Superior dimensional stability

Black Aluminum Oxide Performance Parameters

| Item | Test Conditions | Unit | Test Results | Test Standards |

|---|---|---|---|---|

| Color | Black | Q/GTT002 | ||

| Density | g/cm3 | ≥3.60 | GB/T14619-2013 | |

| Water absorption | % | 0 | GB/T14619-2013 | |

| Vickers Hardness | Load 4.9N | GPa | ≥11 | GB/T14619-2013 |

| Flexural Strength | Distance 80mm | MPa | ≥270 | Q/GTT002 |

| Thermal Expansion | 200℃ | 1×10-6/C-1 | 6~6.8 | GB/T14619-2013 |

| 500℃ | 1×10-6/C-1 | 6.9~7.2 | GB/T14619-2013 | |

| 800℃ | 1×10-6/C-1 | 7.6~8 | GB/T14619-2013 | |

| Thermal Conductivity | 25℃ | W/(m.k) | 11~17 | GB/T14619-2013 |

| Dielectric Strength | KV/mm | ≥15 | GB/T14619-2013 | |

| Volume resistivity | 25℃ | Ω.cm | ≥1013 | GB/T14619-2013 |

| 300℃ | Ω.cm | ≥108 | GB/T14619-2013 | |

| 500℃ | Ω.cm | ≥106 | GB/T14619-2013 | |

| Dielectric Constant | 1MHz | 8~10 | GB/T14619-2013 | |

| Dielectric loss | 1MHz | 3×10-4 | GB/T14619-2013 | |

| Hermal Shock | 250-260℃ | No chipping | Q/GTT002 | |

| Surface roughness | Ra | um | <0.8 | Needle Roughness Meter |

Note: Each batch may be different, for reference only.

Note: Please view it on your computer.

Applications of Black Alumina Ceramic Substrates

Black alumina ceramic substrates are primarily used in semiconductor integrated circuits and electronic products. This is mainly due to the high light sensitivity of most electronic products. Packaging materials need to have strong shading properties to ensure the clarity of the digital display. It is packaged on a black alumina ceramic substrate.

Professional Black Alumina Ceramics Company

Great Ceramic is a leading supplier of high quality alumina products and solutions. Drawing on our extensive expertise in materials science and manufacturing processes, we provide customized ceramic components to meet our customers' specific needs.