When we talk about advanced ceramics, one material often stands out for its unusual balance of properties: beryllium oxide, often abbreviated as BeO. If you've ever wondered why certain high-power electronic devices stay cool even when running hot, or why some nuclear systems rely on ceramics instead of metals, chances are beryllium oxide ceramic is part of the answer.

At its heart, everything about this material begins with a very simple piece of chemistry: the beryllium oxide formula. Written as BeO, this tiny two-letter combination represents a compound that's surprisingly complex in performance.

The Formula of Beryllium Oxide: BeO

The chemical formula for beryllium oxide is one of the simplest in materials science: BeO. It tells us there's a one-to-one ratio of beryllium atoms (Be) to oxygen atoms (O).

This formula of beryllium oxide is both empirical and molecular—there's no simpler way to write it. In academic and industrial contexts, you'll often see it written as:

-

Beryllium oxide formula = BeO

-

BeO compound name = beryllium oxide

-

Sometimes shortened to beryllia in ceramics literature

For buyers or technicians reviewing specs, keep in mind that any reference to beo beryllium oxide or simply berylium oxide (sometimes misspelled without the extra "l") points to the same material.

Oxidation Number of Beryllium in BeO

To balance the charges in BeO, beryllium carries an oxidation number of +2, while oxygen carries −2.

This oxidation state of beryllium is the only stable one in nature—unlike transition metals, it doesn't vary. In fact, whenever you see beryllium oxidation number, oxidation number for beryllium, or oxidation number of beryllium, the answer is always +2.

This matters because that small, highly charged Be²⁺ ion strongly polarizes the oxygen anion. The result is a bond with both ionic and covalent character, giving BeO unique stability, hardness, and—most importantly—exceptional thermal conductivity.

What Is the Molar Mass of Beryllium Oxide BeO?

For anyone calculating material requirements, the molar mass of beryllium oxide BeO is essential. Using IUPAC atomic weights:

- Beryllium (Be): 9.012 g/mol

- Oxygen (O): 15.999 g/mol

- Total: 25.011 g/mol

So the molar mass of BeO ≈ 25.0 g/mol.

This figure is standard across databases like PubChem (CID 14775) and NIST Chemistry WebBook. For engineers, it helps in mass-to-mole conversions, stoichiometry during synthesis, and density verification.

Physical and Chemical Properties of BeO

Let's move from formula to facts. Below are the properties that make beryllium oxide ceramic so valuable.

Appearance and Structure

- White crystalline solid in pure form

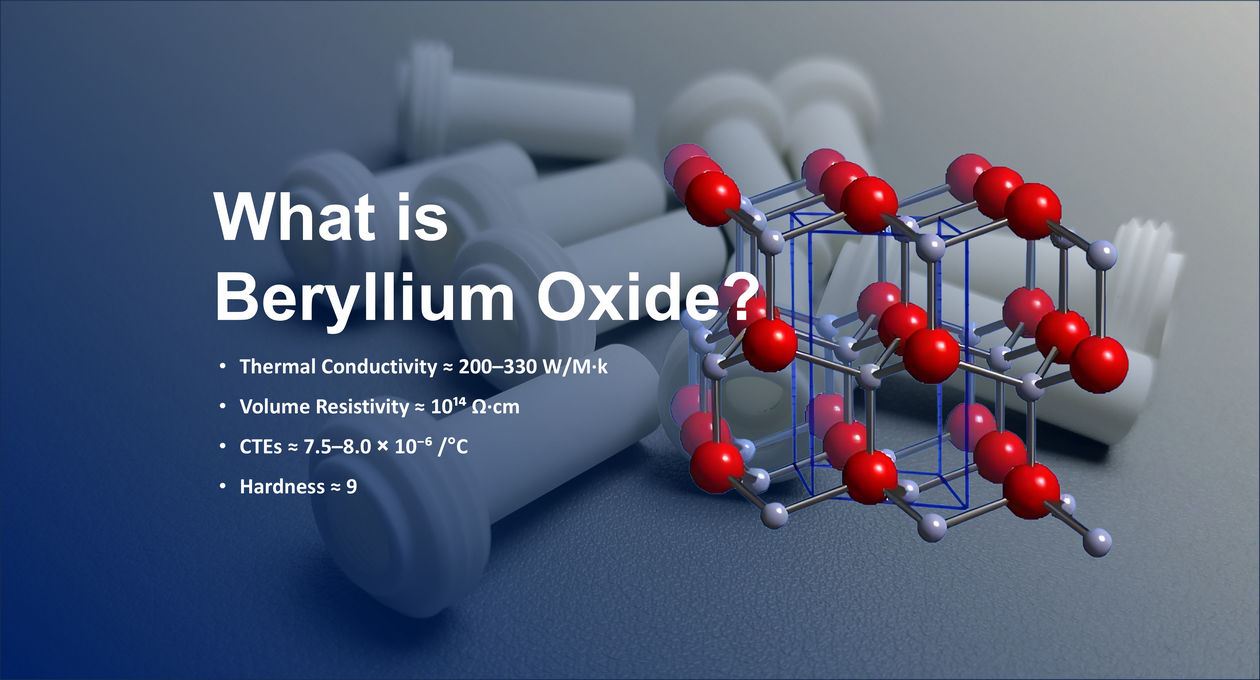

- Wurtzite-type hexagonal crystal structure at room temperature

- Stable cubic form at higher pressures

Physical and Chemical Properties of BeO

Let's move from formula to facts. Below are the properties that make beryllium oxide ceramic so valuable.

Appearance and Structure

Key Properties

| Property | Value |

| Chemical Formula | BeO |

| Molar Mass | ~25.01 g/mol |

| Density | ~3.01 g/cm³ at 25 °C |

| Melting Point | 2,530 – 2,575 °C |

| Boiling Point | ~3,900 – 4,000 °C |

| Thermal Conductivity | 200 – 330 W/m·K (second only to diamond among insulators) |

| Electrical Resistivity | > 10¹³ Ω·cm |

| Thermal Expansion Coefficient | ~7.5 × 10⁻⁶ /°C |

| Hardness (Mohs) | ~9 |

| Dielectric Constant | ~6.7 at 1 MHz |

Chemical Behavior

These numbers explain why BeO is in a league of its own compared to alumina (Al₂O₃) or magnesia (MgO).

How Beryllium Oxide Ceramics Are Made

Production process of beryllium oxide ceramics

Applications of BeO Ceramics

Thanks to its unique combination of properties, beryllium ceramic has a wide range of industrial uses.

Why BeO Beats Traditional Ceramics

Compared to aluminum oxide (Al₂O₃) or silicon nitride (Si₃N₄), BeO stands out in three ways:

Safety and Handling of Beryllium Oxide

Great Ceramic's Advantage

At Great Ceramic, we provide beryllium oxide ceramics that balance performance, precision, and safety.

Quick Reference (for busy readers)

Rapid Ceramic Prototyping & Small‑Batch Manufacturing

The beryllium oxide formula may look simple, but the material it represents is anything but. BeO ceramics combine unmatched thermal conductivity with excellent electrical insulation and high-temperature stability. From high-power transistors to nuclear reactors, BeO is where conventional ceramics fall short.

For technicians, it means reliable performance in extreme environments. For R&D engineers, it's a material worth experimenting with. For procurement professionals, it's an investment in long-term performance.

At Great Ceramic, we don't just sell BeO—we deliver the confidence that comes with materials engineered for the future.