In the world of advanced materials, aluminum nitride ceramics stand out due to their impressive properties and wide range of applications. These ceramics are known for their high thermal conductivity and excellent electrical insulation, making them ideal for various industrial applications. In this article, we will explore the benefits of aln ceramics and understand why they are gaining popularity in different sectors.

What Are Aluminum Nitride Ceramics?

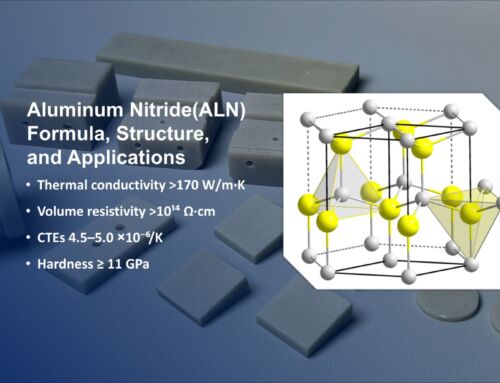

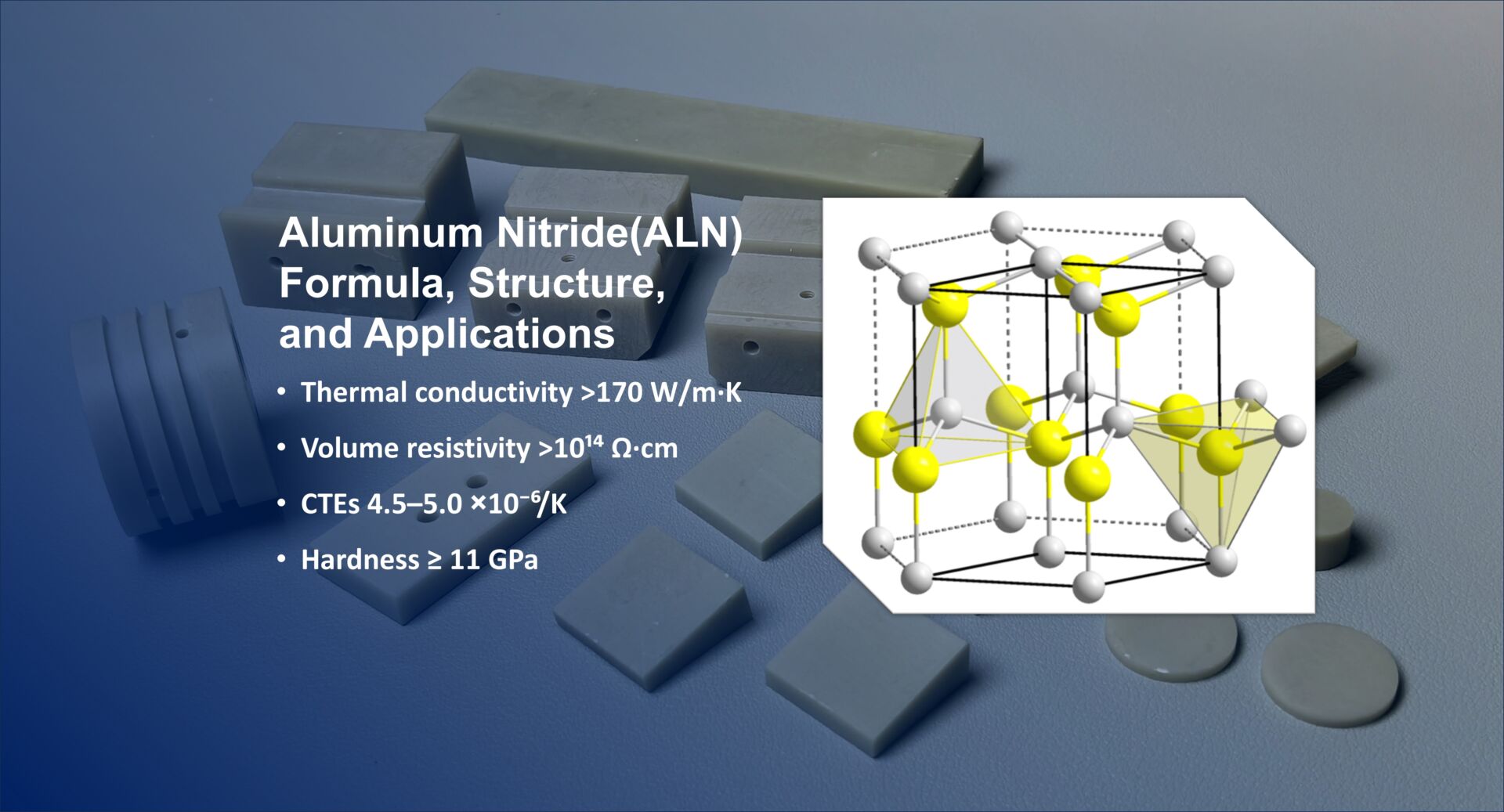

Aluminum nitride (AlN) ceramics are a type of advanced ceramic material composed of aluminum and nitrogen. They are synthesized through a process that involves high temperatures and controlled conditions to achieve their desired properties. The result is a material that is both strong and versatile, making it a preferred choice in many high-tech industries.

Composition and Structure

Aluminum nitride ceramics are primarily composed of aluminum and nitrogen, forming a covalent bond that contributes to their strength and stability. The crystalline structure of these ceramics is typically hexagonal, which plays a crucial role in their thermal and electrical properties. Understanding the composition and structure is essential for tailoring the ceramics for specific applications.

Synthesis Process

The synthesis of aluminum nitride ceramics involves a series of high-temperature reactions that facilitate the combination of aluminum and nitrogen. This process often requires a controlled environment to ensure the purity and quality of the final product. Advanced techniques such as carbothermal reduction or direct nitridation are employed to achieve the desired material characteristics.

Historical Development

The exploration and development of aln ceramics have a rich history, dating back to the mid-20th century. Initially developed for military applications, these ceramics have since found their way into commercial industries. Understanding the historical context can provide insights into the evolution of their properties and applications.

Key Properties of Aluminum Nitride Ceramics

Aluminum nitride ceramics possess several key properties that make them advantageous for various applications.

High Thermal Conductivity

One of the most significant benefits of aln ceramics is their high thermal conductivity. This property allows them to efficiently transfer heat, making them ideal for applications where heat dissipation is crucial. With a thermal conductivity value that can reach up to 175 W/mK, aln ceramics outperform many other ceramic materials in this regard.

Electrical Insulation

Aluminum nitride ceramics are excellent electrical insulators, which means they can prevent the flow of electric current. This characteristic is vital in applications that require both thermal management and electrical isolation, such as in electronic devices and components.

Dielectric Properties

Beyond electrical insulation, aluminum nitride ceramics also exhibit favorable dielectric properties. These properties are important for high-frequency applications, such as RF and microwave technologies. By minimizing energy loss, these ceramics enhance the efficiency of telecommunication systems.

High Mechanical Strength

These ceramics also boast high mechanical strength, which contributes to their durability and longevity. This makes them suitable for applications that involve mechanical stress or require materials with robust structural integrity.

Stress Resistance

The mechanical strength of aluminum nitride ceramics enables them to withstand significant stress without deforming or breaking. This property is crucial in environments where materials are subjected to heavy loads or impacts. Engineers often leverage this strength in designing components for aerospace and defense applications.

Longevity and Wear Resistance

The wear resistance of aln ceramics ensures that components last longer even in abrasive conditions. This durability reduces maintenance costs and downtime, making them cost-effective for long-term use. Industries such as manufacturing and construction benefit greatly from this property.

Chemical Stability and Corrosion Resistance

Aluminum nitride ceramics exhibit remarkable chemical stability, meaning they are resistant to chemical reactions that could degrade the material. They also offer excellent corrosion resistance, which is essential for applications exposed to harsh environments.

Stability in Harsh Environments

The chemical stability of aluminum nitride ceramics makes them ideal for use in environments where they are exposed to chemicals or extreme conditions. This stability ensures that they maintain their properties over time, reducing the risk of failure. Industries such as chemical processing and energy generation benefit from this reliability.

Resistance to Oxidation

Aluminum nitride ceramics resist oxidation at high temperatures, maintaining their structural integrity in oxygen-rich environments. This property is particularly important in applications involving high-temperature processes. By resisting oxidation, these ceramics ensure consistent performance and longevity.

Applications of ALN Ceramics

The unique properties of aluminum nitride ceramics make them suitable for a wide range of applications across various industries.

Substrates for Integrated Circuits

In the realm of integrated circuits, aln ceramics are used as substrates due to their ability to support miniaturization without compromising performance. Their thermal conductivity ensures that heat is efficiently managed, preventing damage to sensitive components. As electronic devices become more compact, the demand for such substrates continues to grow.

Thermal Management in LED Systems

Efficient thermal management is essential in LED systems to maintain brightness and prolong lifespan. aln ceramics, with their superior thermal conductivity, provide a solution to this challenge. By dissipating heat effectively, they enhance the performance and reliability of LED lighting systems.

Environmental Impact and Efficiency

The use of aln ceramics in LED technology supports the development of eco-friendly lighting solutions. By improving energy efficiency and reducing heat generation, these ceramics help decrease the carbon footprint of lighting systems. This aligns with global efforts to promote sustainable and energy-efficient technologies.

Telecommunication Equipment

The telecommunication industry also benefits from aluminum nitride ceramics, as they are used in the production of RF (radio frequency) components. These components require materials that can handle high frequencies while maintaining thermal stability and electrical insulation.

RF Component Manufacturing

In RF component manufacturing, materials that offer both thermal stability and electrical insulation are critical. aln ceramics meet these requirements, ensuring that RF components operate efficiently at high frequencies. Their use in telecommunications is pivotal for the development of reliable communication systems.

Expansion in 5G Technology

As the telecommunication industry transitions to 5G technology, the demand for materials like aluminum nitride ceramics is increasing. These ceramics support the higher frequencies and data rates required for 5G networks, facilitating their rollout and adoption. Their role is crucial in the evolution of next-generation communication technologies.

Automotive Industry

In the automotive sector, aln ceramics find applications in power electronics and sensors. Their ability to manage heat and provide electrical insulation makes them valuable in electric vehicles and other automotive technologies.

Role in Electric Vehicles

Electric vehicles (EVs) demand materials that can efficiently manage heat and provide electrical insulation. Aluminum nitride ceramics meet these demands, enhancing the performance and safety of EV components. Their contribution is vital for the development of sustainable and efficient transportation solutions.

Manufacturing and Processing of Aluminum Nitride Ceramics

The production of aln ceramics involves several key steps to ensure the desired properties are achieved. The process begins with the synthesis of aluminum nitride powder, which is then shaped into the desired form through pressing or molding techniques. Once shaped, the material undergoes a sintering process, where it is heated to high temperatures to densify and strengthen the ceramic.

Powder Synthesis Techniques

Synthesis of aluminum nitride powder is a critical step in manufacturing, involving techniques such as carbothermal reduction and direct nitridation. These methods are designed to produce high-purity powder with controlled particle size and distribution. The quality of the synthesized powder directly impacts the final properties of the ceramic.

Shaping and Forming Methods

After synthesis, the aln powder is shaped into the desired form using techniques like pressing, extrusion, or injection molding. These methods allow for the creation of complex shapes and sizes, tailored to specific applications. The choice of shaping technique affects the density and mechanical properties of the final product.

Sintering and Densification

Sintering is a critical step in the manufacturing process where the shaped aluminum nitride is heated to high temperatures. This process densifies the material, enhancing its mechanical strength and thermal conductivity. Advances in sintering techniques continue to improve the quality and performance of aln ceramics.

Addressing Impurities

Impurities in aln ceramics can significantly affect their properties, particularly thermal conductivity. Manufacturers employ rigorous quality control measures to minimize impurities and ensure consistent product quality. Understanding these challenges is essential for producing reliable and high-performance ceramics.

Technological Innovations

Innovations in manufacturing technology are driving improvements in the production of aln ceramics. Techniques such as advanced sintering and additive manufacturing are enhancing the efficiency and quality of production. These advancements are critical for meeting the growing demand for high-performance ceramics.

The Future of Aluminum Nitride Ceramics

The demand for aluminum nitride ceramics is expected to grow as industries continue to seek materials that offer superior thermal management and electrical insulation. With ongoing research and development, we can anticipate further improvements in the properties and applications of these ceramics.

Innovations and Advancements

Recent advancements in the production of aluminum nitride ceramics include the development of nanostructured materials that offer even higher thermal conductivity and mechanical strength. These innovations have the potential to open up new applications and expand the use of aluminum nitride ceramics in emerging technologies.

Nanotechnology and Material Design

The integration of nanotechnology in the design of aluminum nitride ceramics is leading to materials with enhanced properties. Nanostructured ceramics offer improved thermal and mechanical characteristics, paving the way for their use in cutting-edge applications. The exploration of nanotechnology continues to be a focal point in advancing ceramic materials.

Emerging Applications

As aluminum nitride ceramics evolve, new applications are emerging in fields such as quantum computing, advanced sensor technology, and next-generation electronics. These materials provide the performance needed for innovative technologies that demand precision and reliability. The exploration of these new frontiers is expanding the role of aluminum nitride ceramics.

Collaborations and Research Initiatives

Collaborations between research institutions, industry leaders, and academia are driving innovation in aluminum nitride ceramics. These partnerships are essential for advancing the understanding and application of these materials. Ongoing research initiatives are expected to yield breakthroughs that further enhance their capabilities.

Conclusion

Aluminum nitride ceramics have emerged as a vital material in various industries due to their unique combination of high thermal conductivity, electrical insulation, and mechanical strength. As technology continues to advance, the role of aluminum nitride ceramics is likely to become even more significant. Whether in electronics, automotive, or telecommunications, these ceramics provide the performance and reliability needed for modern applications. As research progresses, we can expect to see even more innovative uses for aluminum nitride ceramics, further solidifying their place in the world of advanced materials.