- Home

- Technical Ceramics Category And Application

- Aluminum Nitride (ALN) Ceramic Substrate laser Cutting

Aluminum Nitride (ALN) Ceramic Substrate laser Cutting

- Provide custom processing services

- Very high thermal conductivity

- Excellent electrical insulation properties

AlN Ceramic Substrate Laser Cutting Overview

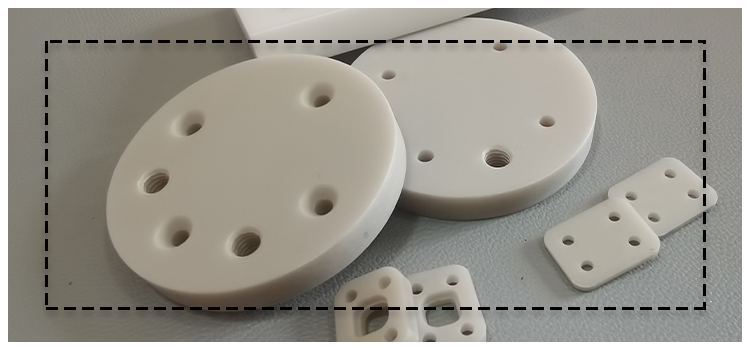

Aluminum nitride (AlN) ceramic substrate is a technical ceramic material with excellent performance, which has a wide range of applications in semiconductor, optoelectronics, aerospace and other fields.

Laser cutting is one of the important processes in the processing of AlN ceramic substrates, which has the advantages of fast cutting speed, high precision, and no pollution.

AlN ceramic substrate has the following characteristics:

- High thermal conductivity: The thermal conductivity of AlN ceramic substrate can reach 170W/m·K, which is 5-8 times that of alumina ceramic substrate, and has good heat dissipation performance.

- High electrical insulation: The electrical insulation strength of AlN ceramic substrate can reach 1000V/mm, and it has good electrical insulation performance.

- High strength: The bending strength of AlN ceramic substrate can reach 380MPa, and it has good mechanical properties.

- High wear resistance: AlN ceramic substrate has good wear resistance and can withstand high-intensity friction.

- High corrosion resistance: AlN ceramic substrate has good corrosion resistance and can resist the erosion of various acid and alkali solutions.

Laser cutting AlN ceramic substrates has the following advantages:

- Fast cutting speed: Laser cutting is an efficient processing technology that can quickly cut out precise graphics and sizes.

- High precision: laser cutting has high processing precision, which can meet the requirements of complex graphics and dimensions.

- Burr-free: Laser cutting can achieve burr-free cutting and ensure the smoothness of the cutting surface.

- Pollution-free: Laser cutting is a clean process that does not produce pollution.

The application of aluminum nitride ceramic substrate mainly includes:

- In the field of power electronics: AlN ceramic substrates are ideal substrates for power electronic devices, and can be used for the packaging of power modules, IGBTs, MOSFETs and other devices.

- Optoelectronics field: AlN ceramic substrate is an ideal substrate for optical components, and can be used for laser diodes, LEDs, photovoltaic cells and other devices.

- Semiconductor field: AlN ceramic substrate is an ideal substrate for semiconductor devices, and can be used for chip packaging, wafer cutting, etc.

Aluminum Nitride Ceramics Supply Company

Great Ceramic has been engaged in the work of precision technical ceramics for many years, and has rich experience in the milling, grinding and polishing of Aluminum nitride (AlN) Ceramics. We can:

- Make products according to the requirements of the drawings;

- Manufacturing more complex products;

- Achieve higher dimensional accuracy;

- Realize quick response and delivery;

- Provide more professional services.

Great Ceramic can improve all tolerances according to the size and structure of precision advanced ceramic products. Great Ceramic is committed to ensuring that we only produce the highest quality precision ceramic parts that meet or exceed customer specifications.

Contact us to find out what we can do for you!

- We will reply to your message within 24 hours;

- We can provide you with technical consulting services;

- We support any number of product customization;

- We are happy to provide service for you.

Packing and Shipping

Great Ceramic’s aluminum nitride ceramic substrate has been carefully processed to minimize damage during storage and transportation and maintain the quality of our products in the original state.