Поддержка приложений и дизайна

На сайте Отличная керамикаМы не просто производим прецизионные керамические детали - мы сотрудничаем с вами от концепции до применения. Разрабатываете ли вы электронные компоненты нового поколения, решения для терморегулирования или механические системы, требующие экстремальных характеристик, наши поддержка приложений и разработок гарантирует, что вы получите правильный современные керамические материалы и компоненты, изготовленные на заказ-Быстрее и эффективнее.

Всесторонняя поддержка от выбора материала до окончательного нанесения

Выбор правильного техническая керамика имеет решающее значение для производительности, экономичности и долгосрочной надежности. Наша команда опытных инженеров-керамистов и технических специалистов поможет вам в этом:

Мы тесно сотрудничаем с инженерами-исследователями, руководителями проектов и специалистами по закупкам в таких отраслях, как полупроводники, аэрокосмическая промышленность, медицинские приборы, энергия, и промышленное оборудование.

Экспертное руководство по выбору керамического материала

Выбор правильного керамического материала может значительно улучшить производительность и долговечность вашего изделия. Компания Great Ceramic предлагает широкий ассортимент передовая техническая керамика, в том числе:

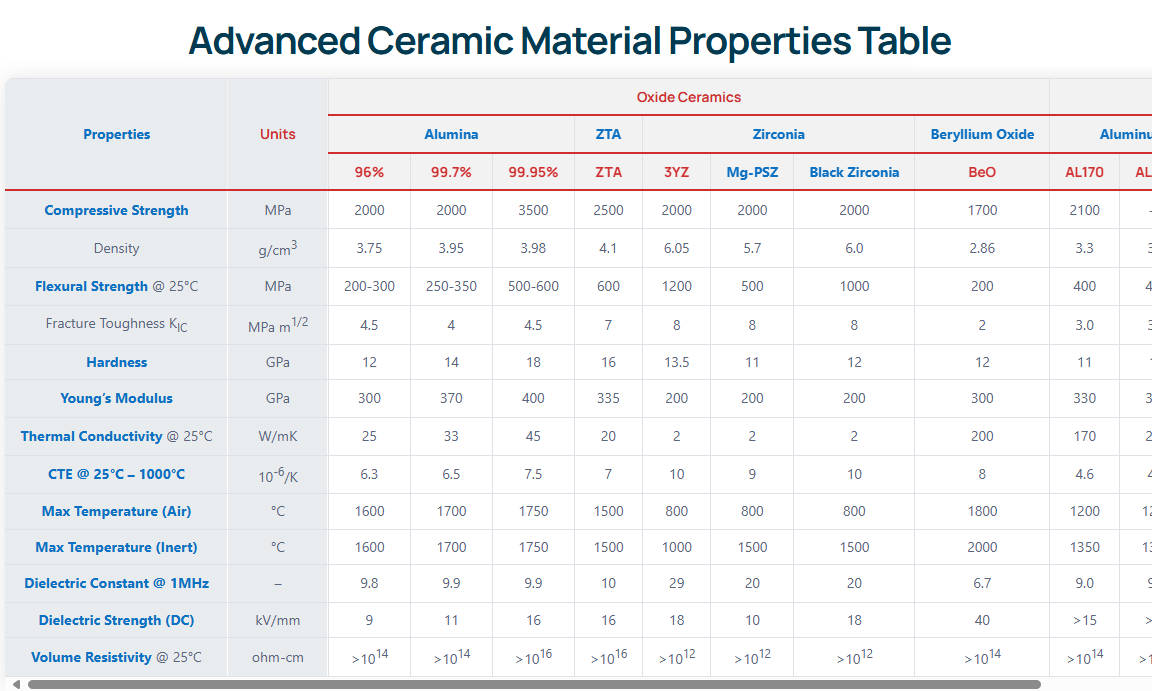

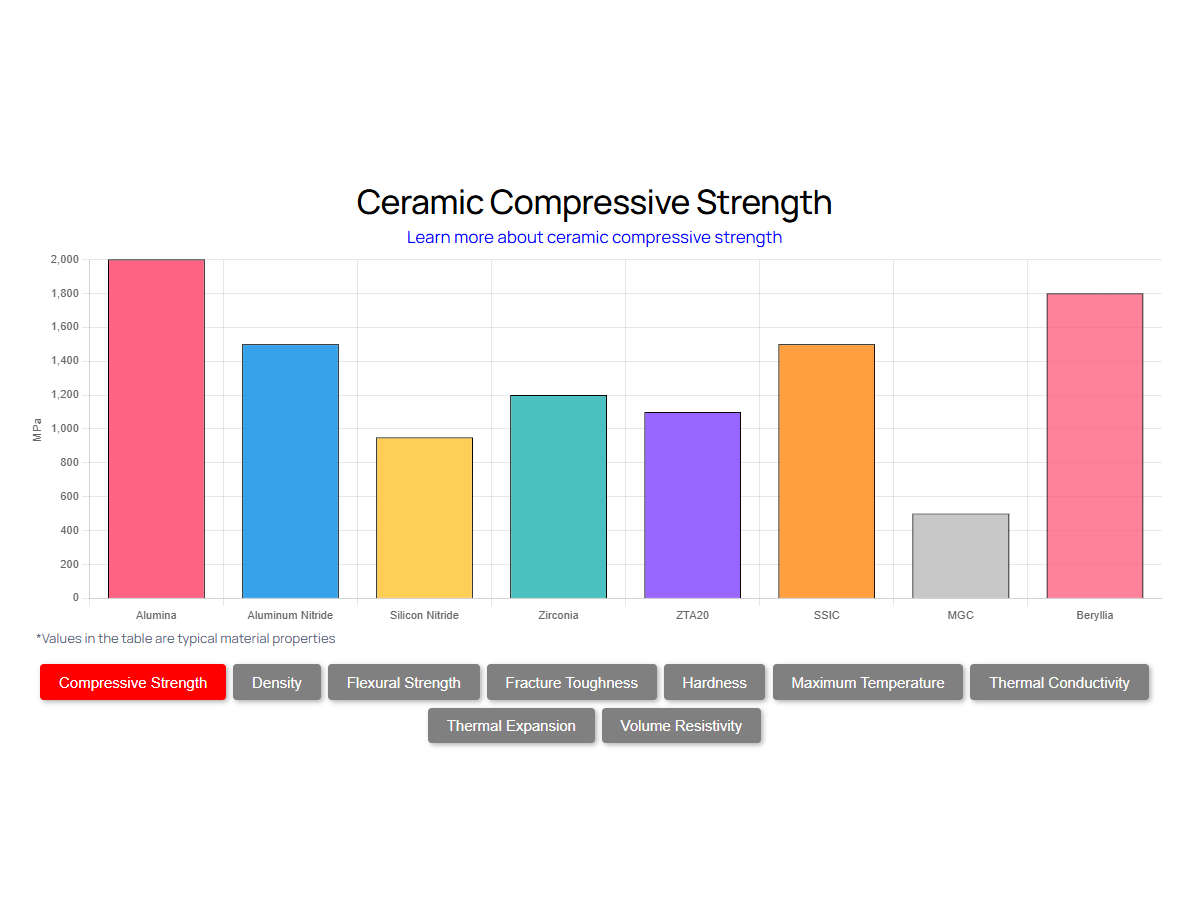

Мы поможем вам оценить механические свойства, теплопроводность, диэлектрическую прочность, объемное сопротивление и химическую совместимость каждого материала, чтобы гарантировать, что ваш продукт соответствует функциональным требованиям.

Инструмент для выбора керамического материала

Оптимизация конструкции для повышения производительности и технологичности

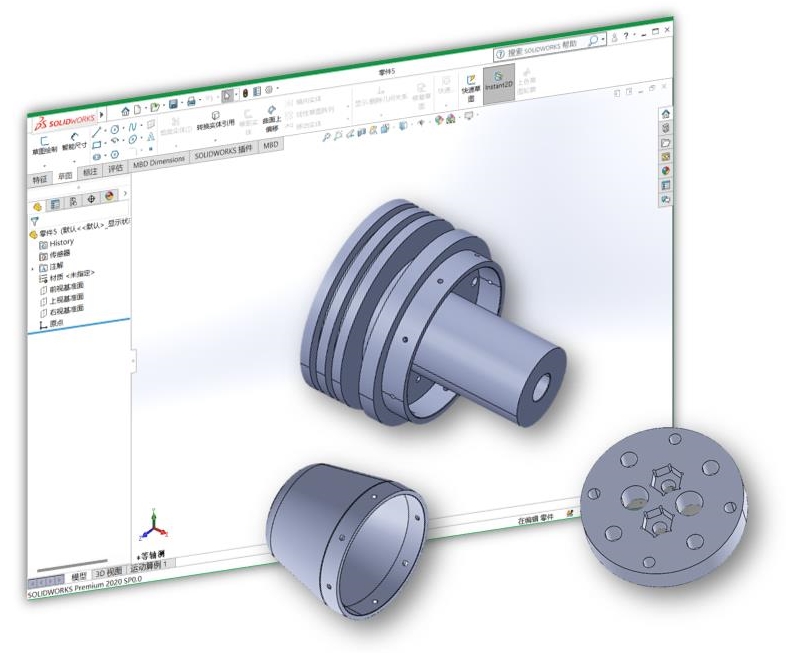

Наши инженеры сотрудничают с вами, чтобы превратить вашу первоначальную концепцию в готовый к производству дизайн. Мы поддерживаем:

Мы стремимся сократить время выполнения заказа, минимизировать затраты и повысить технологичность без ущерба для ваших целей.

Быстрое прототипирование и малосерийное производство

Неважно, находитесь ли вы на ранней стадии разработки или дорабатываете продукт для запуска, Отличная керамика предлагает быстрое прототипирование и малосерийное производство для ускорения циклов разработки. Наши собственные возможности обработки позволяют:

Эта услуга идеально подходит для исследовательских институтов, стартапов и пилотных проектов.

Разработка приложений и интеграция конечных пользователей

Керамические компоненты часто работают в сложных узлах и экстремальных условиях. Мы предоставляем подробную информацию прикладная инженерия поддержка для обеспечения беспрепятственной интеграции:

Часто задаваемые вопросы (FAQ)

Почему стоит выбрать Great Ceramic?

Идет ли речь о повышении тепловой эффективности, увеличении долговечности компонентов или решении инженерной задачи, Отличная керамика является вашим надежным партнером в области технических керамических решений.