실리콘 카바이드(SiC) 세라믹

19세기 후반부터 카보룬듐 실리콘 카바이드 세라믹(SiC)으로 알려진 이 실리콘과 탄소 화합물은 연마 분말에서 고성능 엔지니어링의 초석 재료로 발전했습니다. 오늘날 실리콘 카바이드 세라믹은 반도체와 전자 제품부터 항공우주, 자동차, 에너지, 화학 공정에 이르기까지 다양한 산업에서 없어서는 안 될 필수 요소입니다.

실리콘 카바이드란 무엇인가요? 과학적 용어로 화학식 SiC를 갖는 공유 결합 탄화규소 화합물로, 다양한 폴리타입(3C, 4H, 6H)으로 존재할 수 있는 독특한 결정 구조를 나타냅니다. 높은 경도(Mohs 9.5), 낮은 밀도(~3.1g/cm³), 높은 용융 온도(~2,700°C), 뛰어난 탄화규소 열전도율로 금속이나 플라스틱이 실패하는 까다로운 애플리케이션에 이상적입니다.

Great Ceramic은 고객의 요구 사항에 맞춘 엔지니어링 실리콘 카바이드 부품을 제공하여 탁월한 정밀도, 일관성 및 신뢰성을 제공합니다.

실리콘 카바이드 세라믹의 장점

기계적, 열적, 전기적 특성의 독특한 조합으로 인해 SiC는 테크니컬 세라믹 중에서도 단연 돋보입니다.

사용 가능한 실리콘 카바이드 소재의 등급

Great Ceramic은 애플리케이션별로 최적화된 다양한 고성능 실리콘 카바이드 소재를 제공합니다:

무압 소결 실리콘 카바이드 세라믹(SSIC)

무압 소결 실리콘 카바이드 세라믹(SSiC)은 고온, 무압 소결 공정을 통해 생산되는 고성능 구조용 세라믹입니다. 주성분은 고순도 실리콘 카바이드 분말입니다. 소결 과정에서 금속 바인더나 외부 압력이 필요하지 않으므로 순도와 밀도가 매우 높아 전반적인 성능이 뛰어납니다. 이 소재는 뛰어난 기계적 강도, 내마모성 및 내식성으로 인해 극도로 혹독한 환경에서 널리 사용됩니다.

주요 기능

일반적인 애플리케이션

생산 프로세스

무압 소결 탄화규소 세라믹은 고순도 SiC 분말로 만든 다음 소량의 소결 보조제를 사용하여 금형에 형성하고 2000°C 이상의 온도에서 무압으로 소결합니다. 이 과정을 통해 소재는 이론 밀도에 가까운 조밀한 구조와 미세하고 균일한 입자를 가지게 되어 우수한 종합 성능을 보장합니다.

반응 소결 실리콘 카바이드 세라믹(SISiC)

반응 소결 실리콘 카바이드 세라믹(SISiC)은 실리콘 카바이드(SiC) 분말과 탄소 공급원으로 만든 고성능 세라믹 소재입니다. 액체 실리콘을 고온에서 녹색 몸체에 침투시켜 새로운 실리콘 카바이드를 생성하는 반응을 일으킵니다. SISiC는 무압 소결 실리콘 카바이드(SSiC)에 비해 생산 온도가 낮고 공정이 유연하여 대형 및 복잡한 형태의 구조 부품을 제작할 수 있습니다. 따라서 산업 분야에서 폭넓게 활용되고 있습니다.

주요 기능

일반적인 애플리케이션

생산 프로세스

반응 소결 실리콘 카바이드의 준비 과정에는 일반적으로 다음이 포함됩니다:

이 방법의 장점은 간단한 공정, 낮은 소결 온도, 최소한의 치수 수축을 통해 순 치수에 가까운 크고 복잡한 부품을 생산할 수 있다는 점입니다. 하지만 잔류 실리콘이 존재하기 때문에 고온 강도와 내산화성이 SSiC에 비해 약간 떨어집니다.

실리콘 카바이드의 주요 특성

그레이트 세라믹은 고객이 선택할 수 있는 다양한 실리콘 카바이드 소재를 제공합니다. 다음 값은 일반적인 재료 특성이며 제품 구성 및 제조 공정에 따라 달라질 수 있습니다. 자세한 내용은 다음 연락처로 문의하시기 바랍니다. 문의하기.

| 속성 | 단위 | SSiC | SiSiC | Si3N4 |

|---|---|---|---|---|

| 색상 | -- | 짙은 회색 | 짙은 회색 | 회색 또는 검은색 |

| 밀도 | g/cm³ | 3.15 | 3.02 | 3.2 |

| 다공성 | % | ≤0.1 | ≤0.1 | -- |

| 경도 | GPa | 22 | 22 | 15 |

| 압축 강도 | MPa | 2600 | 2600 | 2500 |

| 굴곡 강도 | MPa | 400 | 250 | 700 |

| 탄성 계수 | GPa | 410 | 330 | 300 |

| 최대 사용 온도 | ℃ | 1400 | 1000 | 1100 |

| 열 전도성 | W/(m・K) | 100~120 | 45(1200℃) | 15~20 |

| 열팽창 계수 | 1 x 10-6/°C | 4 | 4.5 | 3 |

탄화규소 소재의 화학적 특성

산소 반응의 온도가 1300°C에 도달하면 탄화규소 결정 표면에 이산화규소의 보호 층이 형성됩니다. 보호 층이 두꺼워지면 내부 탄화 규소가 저항하고 계속 결합하여 탄화 규소 결정 실리콘 카바이드가 우수한 내 화학성을 갖도록합니다. 내식성 측면에서 SiC 재료는 이산화 규소 보호막의 역할로 인해 내산성이 강하지 만 내 알칼리성이 좋지 않습니다.

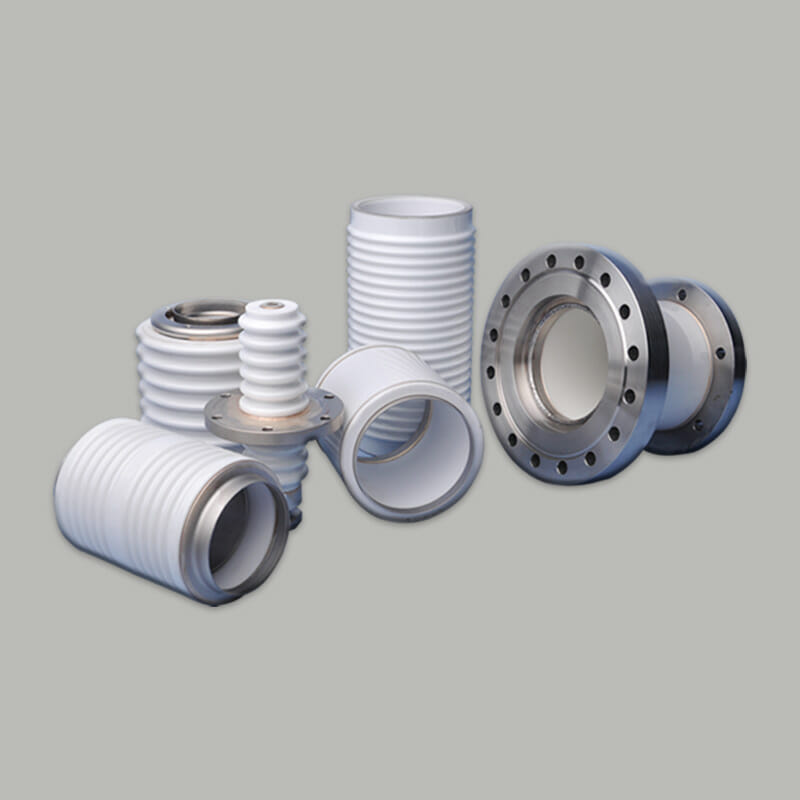

실리콘 카바이드 세라믹 적용 사례

Great Ceramic’s silicon carbide (SiC) ceramics combine outstanding hardness, excellent thermal conductivity, superior wear resistance, and exceptional chemical stability, making them one of the most advanced ceramic materials for demanding industrial applications. With a high melting point, low thermal expansion, and ability to withstand extreme environments, silicon carbide ceramics are ideal for industries that require durability, efficiency, and long service life.

실리콘 카바이드 세라믹의 주요 응용 분야:

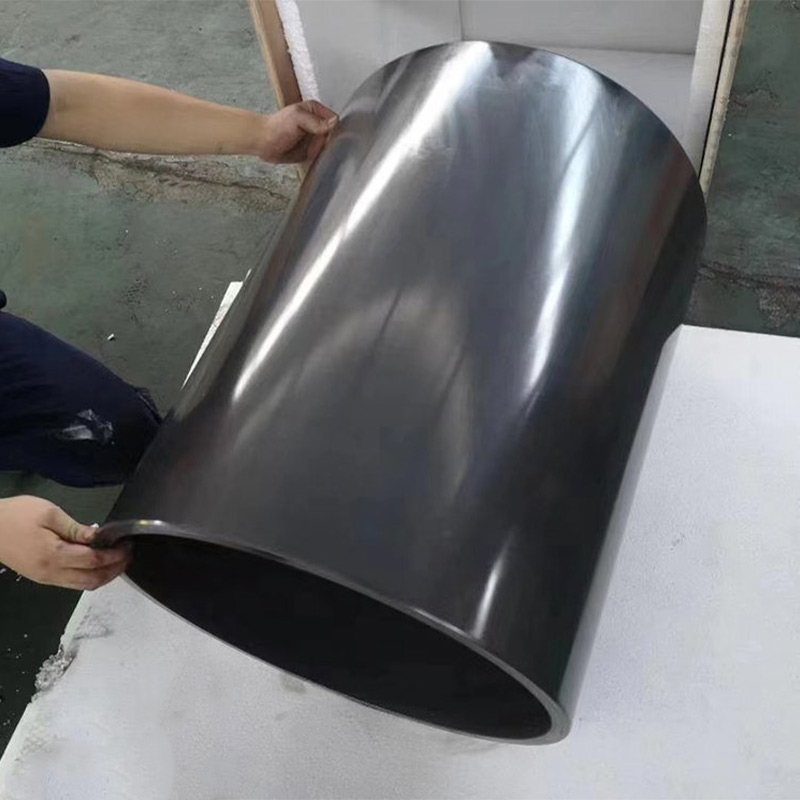

실리콘 카바이드 세라믹 가공

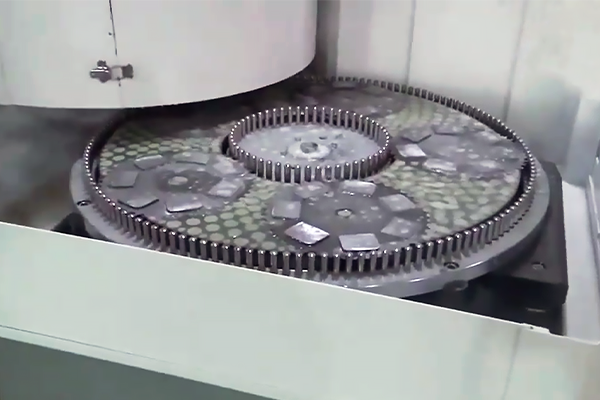

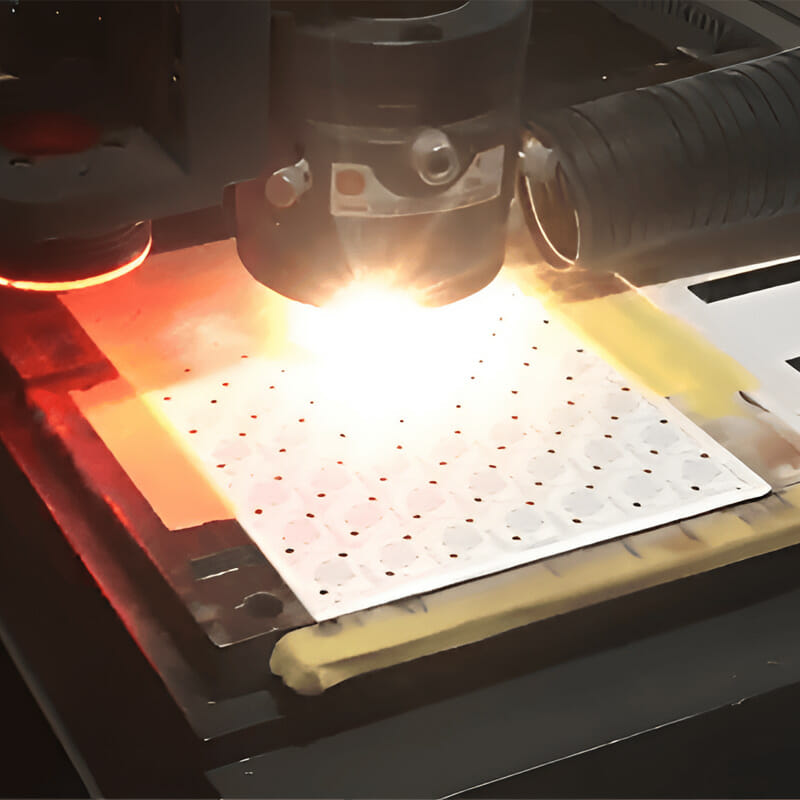

실리콘 카바이드(SiC) 세라믹은 극한의 경도, 높은 열전도율, 우수한 내마모성으로 잘 알려져 있어 가공하기 가장 까다로운 기술 세라믹 중 하나입니다. 그레이트 세라믹은 업계 최고의 정밀도, 성능 및 신뢰성을 제공하는 종합적인 실리콘 카바이드 가공 서비스를 제공합니다.

가공 과정에서 고급 다이아몬드 연삭, 정밀 래핑 및 미세 연마 기술을 사용하여 미크론 수준의 공차와 탁월한 표면 마감을 달성합니다. 이러한 역량을 통해 기계식 씰, 반도체 기판, 도가니, 열교환기, 항공우주 부품의 엄격한 구조 정확도와 표면 품질 요건을 충족할 수 있습니다.

그레이트 세라믹은 다년간의 기술 전문성과 최첨단 장비를 통해 표준화된 실리콘 카바이드 부품을 공급할 뿐만 아니라 특정 산업 요구에 맞는 맞춤형 복합 부품을 개발하여 극한의 작업 조건에서도 높은 신뢰성과 긴 서비스 수명을 보장합니다.

자주 묻는 질문

실리콘 카바이드 세라믹을 위해 당사를 선택하는 이유는 무엇입니까?

에서 그레이트 세라믹당사는 단순한 실리콘 카바이드 세라믹 공급업체가 아닌 정밀 엔지니어링 파트너입니다. 당사의 강점은 다음과 같습니다: