석유 및 가스 산업에서 첨단 세라믹의 응용 분야

석유 및 가스 산업의 운영 환경은 극한의 온도, 고압, 부식성 화학물질, 마모성 조건 등 세계에서 가장 혹독한 환경 중 하나입니다. 기존의 금속과 폴리머는 시간이 지나도 성능을 유지하는 데 어려움을 겪는 경우가 많아 가동 중단과 유지보수 비용이 많이 듭니다. 이러한 상황에서 고급 세라믹 혁신적인 솔루션을 제공합니다.

에서 그레이트 세라믹를 위해 특별히 설계된 정밀 엔지니어링 세라믹 부품을 제공합니다. 석유 및 가스 산업와 같은 재료의 고유한 속성을 활용합니다. 알루미나(Al₂O₃), 지르코니아(ZrO₂), 실리콘 카바이드(SiC), 실리콘 질화물(Si₃N₄)및 질화 붕소(BN). 이러한 기술 세라믹은 타의 추종을 불허하는 내마모성, 열 안정성, 화학적 불활성및 전기 절연업스트림, 미드스트림, 다운스트림 애플리케이션에 필수적인 요소입니다.

왜 석유 및 가스용 고급 세라믹인가?

첨단 세라믹은 기계적 강도, 화학적 내구성 및 열 복원력의 강력한 조합을 제공하여 현대의 석유 및 가스 작업에서 없어서는 안 될 필수 요소가 되었습니다. 시추, 생산, 탐사 등 모든 분야에서 세라믹은 유지보수를 줄이고, 안전을 강화하며, 서비스 수명을 연장하여 비용 효율적이고 신뢰할 수 있는 에너지 솔루션을 지원합니다.

이러한 특성 덕분에 세라믹은 미션 크리티컬한 석유 및 가스 부품에서 금속과 폴리머보다 뛰어난 성능을 발휘합니다.

혜택:

석유 및 가스 분야에서 첨단 세라믹의 주요 응용 분야

석유 및 가스 산업을 위한 일반적인 세라믹 부품

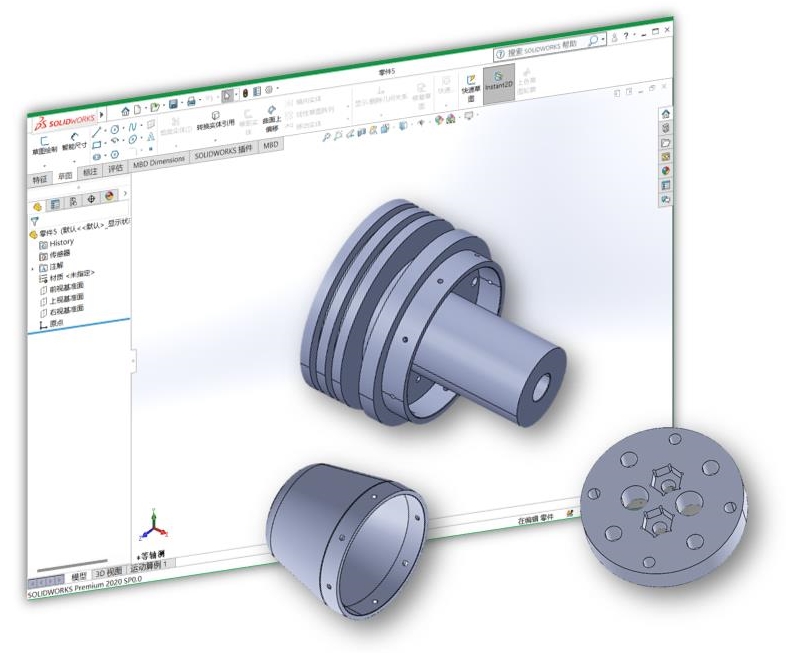

그레이트 세라믹은 석유 및 가스 엔지니어링 분야에서 고성능 세라믹의 사용을 발전시키기 위해 최선을 다하고 있습니다. 당사는 다음 재료로 만든 맞춤형 부품을 제공합니다:

| 세라믹 소재 | 석유 및 가스 애플리케이션 | 주요 속성 |

|---|---|---|

| 알루미나(Al₂O₃) | 밸브 부품, 전기 절연체, 마모 슬리브 | 뛰어난 내마모성, 화학적 안정성, 높은 전기 절연성 |

| 실리콘 카바이드(SiC) | 밸브 시트, 노즐, 머드 펌프 라이너, 모래 제어 스크린 | 뛰어난 경도, 높은 내마모성 및 내식성, 열 전도성 |

| 지르코니아(ZrO₂) | 고압 씰, 플런저, 패커 구성품 | 높은 골절 인성, 내화학성, 단열성 |

| 질화규소(Si₃N₄) | 다운홀 공구, 터빈 유량 제어 부품용 베어링 | 고강도, 우수한 내마모성 및 열충격 저항성 |

| 질화 알루미늄(AlN) | 다운홀 전자 장치, 센서 하우징용 기판 | 뛰어난 방열, 유전체 강도, 열 충격 저항성 |

| MGC(가공 가능한 유리 세라믹) | 정밀 절연체, 센서 베이스, 피드스루 | 손쉬운 가공, 치수 안정성, 유전체 절연성 |

| 질화붕소(BN) | 벌목 도구용 전기 절연체, 단열재 | 높은 열 안정성, 전기 절연성, 화학적 불활성 |

| 베릴륨 산화물(BeO) | 마이크로파 통신 부품, 고주파 장치 | 매우 높은 열 전도성, 전기 절연성 |

그레이트 세라믹의 기능

그레이트 세라믹 의 신뢰할 수 있는 공급업체입니다. 정밀 세라믹 가공 솔루션 그리고 맞춤형 고급 세라믹 부품 석유 및 가스 업계의 요구사항에 맞춘 맞춤형 서비스입니다. 저희가 제공합니다: