セラミックメタライゼーションと金属ろう付けソリューション

で グレート・セラミックを提供する。 プロフェッショナルなセラミック表面メタライゼーションとろう付けサービス 航空宇宙、パワーエレクトロニクス、真空システム、医療機器、半導体製造など、要求の厳しい産業向け。

の深い専門知識を組み合わせる。 テクニカルセラミックス, 精密ろう付けそして セラミックと金属を密封する設計当社は、過酷な環境下でも性能を発揮する、信頼性の高い高性能アセンブリの開発を支援しています。

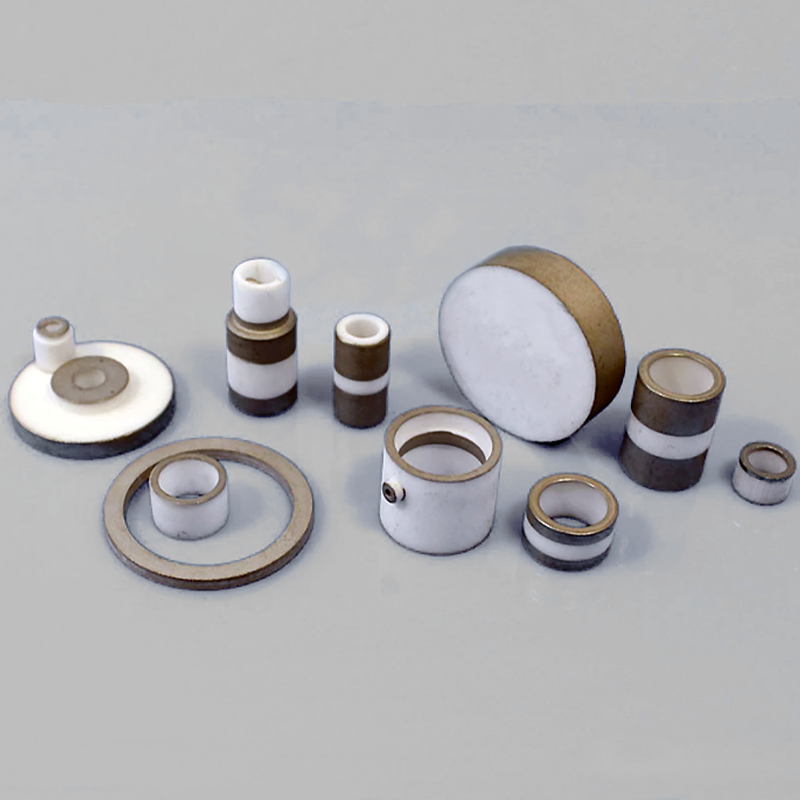

メタライズセラミック部品

メタライズド・セラミック絶縁体

RFウィンドウ、レーザーシステム、センサーハウジングに最適

真空セラミック部品

特定の機械的、電気的、環境的要件に対応

メタライズド・セラミック・チューブ

電子管、熱電対、絶縁体に使用

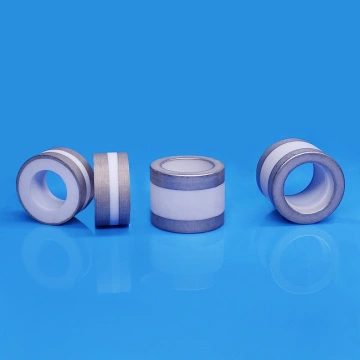

メタライズド・セラミック・リング

真空およびパワーデバイス用密閉フィードスルー

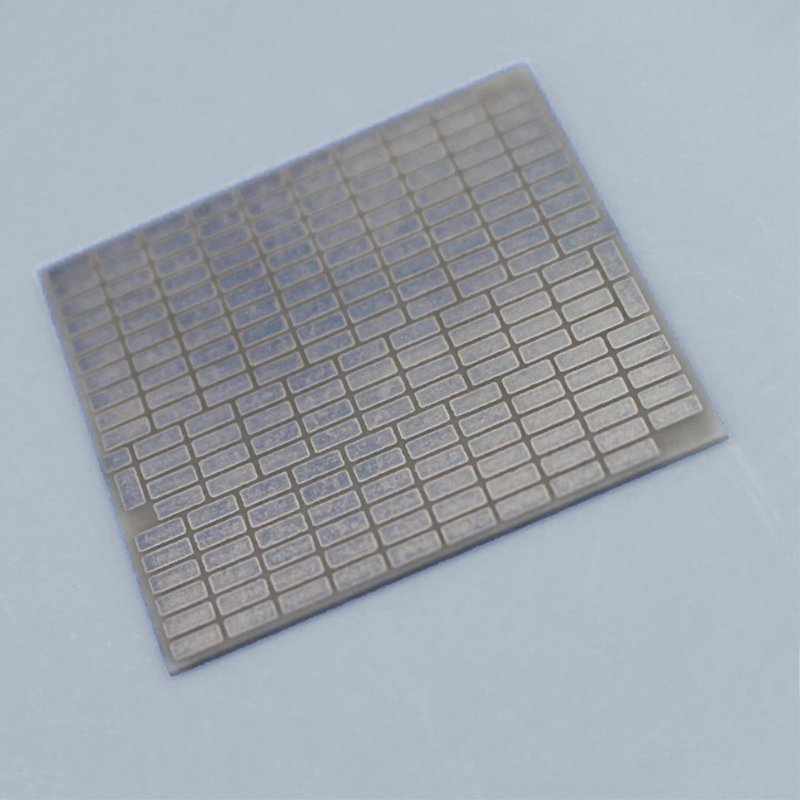

すべてのメタライズ層は、接着性、厚さ、連続性、表面品質について検査されます。メッキ層は、はんだ付け性と耐食性を検査します。

金属化されたセラミック部品は、高温ろう付け技術を用いてコバール、チタン、ステンレス鋼などの金属にろう付けされます。これにより、優れた気密性と機械的信頼性を備えたセラミック-金属アセンブリが形成されます。

Great Ceramicは、お客様の特定の要件を満たす技術的なセラミックろう付け部品を提供できます。当社が提供する部品の多くは、複雑で、厳しい仕様に合わせて設計されているか、特に要求の厳しい重要な用途で使用されています。

セラミックろう付けの特徴

セラミックスと同等の線膨張係数を持つコバール材または無酸素銅を採用し、ろう付けによるセラミックスと金属の密閉を実現。セラミック部品と金属構造部品の気密接続を実現する。このセラミック-金属密閉構造は、高い密閉強度、良好な気密性、高い信頼性という特徴を持っています。

セラミックろう付けおよびシーリング用途

電力・電子機器用真空スイッチ管、各種クライストロン、進行波管、マイクロ波管、マグネトロン、サイラトロン、トリガー、真空計、マイクロ波暗視装置、その他関連真空絶縁産業に使用される。一般的な使用温度は700℃を超えない。

メタライズセラミックスとろう付けアセンブリの用途

私たちの メタライズド・セラミックス そして ろう付け部品 を必要とするクリティカルなタスクに広く使用されています。 気密性、電気絶縁性、熱伝導性そして 機械的強度.