ラピッドセラミックプロトタイピングと小ロット生産

Great Ceramic は、幅広いテクニカルセラミックスのカスタムラピッドセラミックプロトタイピングおよび少量生産を提供します。業界をリードする精密CNC機械加工、超短パルスレーザー切断、ダイヤモンド研磨/琢磨、セラミックから金属へのメタライゼーションおよびろう付け、セラミック成形により、試作品から小規模生産まで高度な設計をサポートします。

グレート・セラミックを選ぶ理由

エキスパート・セラミック材料

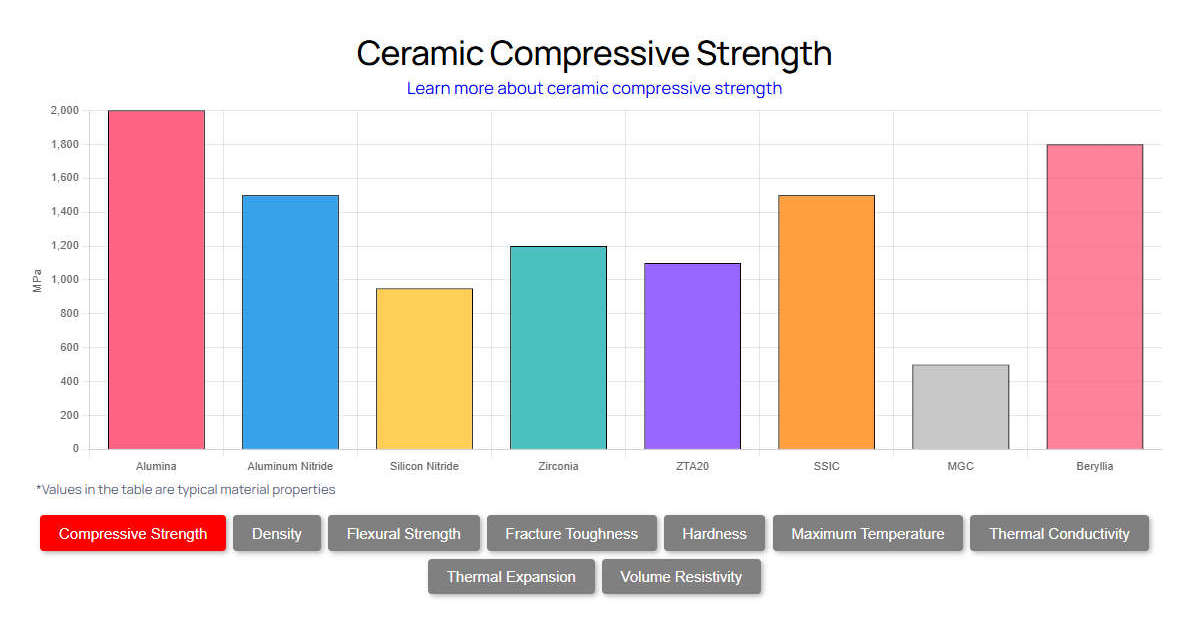

アルミナ(Al₂O₃)、ジルコニア(ZrO₂、ZTA)、窒化ケイ素(Si₃N₄)、炭化ケイ素(SiC)、窒化アルミニウム(AlN)、窒化ホウ素(BN)、酸化ベリリウム(BeO)、機械加工可能なガラスセラミック(MGC)-粉末から完成部品まで供給。

高度な製造能力

信頼の品質とサポート

フルサービスのワークフロー

引用

私たちは、部品の最終設計と製造方法に基づいて、競争力の高い見積もりを提供します:

迅速かつ明瞭な見積りにより、隠れたコストやサプライズは一切ありません。

製造

ご注文後、厳格な品質管理体制のもとで生産されます。

主な製造工程

- 材料構成

- スプレー造粒

- ドライプレス

- アイソスタティック・プレス

- 射出成形

- 鋳造成形

- 熱間静水圧プレス

- 押出金型成形

- 焼結

- ホットプレス焼結

- CNC加工

- 研磨

- 研磨

- レーザー切断

- 表面メタライゼーション

- 溶接

- ISO9001:2016

- 厳しい検査に合格

- 各種試験機

ラピッドセラミックプロトタイピング

精密CNCマシニング、研削/研磨、レーザー加工などの工程で加工し、検査を行います。一般的な納期:15~30日、数量や複雑さによって異なります。

配送

完成した部品は慎重に検査され、梱包されて出荷されます。お客様の時間と品質のご期待に沿えるよう、グローバルな配送オプションをご用意しております。

主要加工素材

| 素材 | ハイライト | 人気のアプリケーション |

|---|---|---|

| アルミナ(Al₂O₃) | 高硬度、優れた絶縁性 | 絶縁体、電子基板 |

| ジルコニア(ZrO₂ / ZTA) | 高い靭性、耐摩耗性 | 構造部品、ハウジング |

| 窒化ケイ素 (Si₃N₄) | 耐熱衝撃性、高強度 | ベアリング、エンジン部品、るつぼ |

| 炭化ケイ素(SiC) | 超硬質、耐薬品性 | 高温および腐食性環境部品 |

| 窒化アルミニウム(AlN) | 高い熱伝導性、断熱性 | 熱管理、半導体ツール |

| 窒化ホウ素(BN) | 乾式潤滑、高温絶縁 | 高耐熱ベアリング&絶縁部品 |

| 酸化ベリリウム (BeO) | 優れた熱特性と電気特性 | RFエレクトロニクス、ヒートスプレッダー |

| 機械加工可能なガラス・セラミック | 機械加工が容易で、試作に最適 | 複雑な構造部品の試作 |

よくある質問

テクニカルセラミックスの信頼できるパートナー

2013年以来、Great Ceramicは高度なセラミックソリューションで世界の革新者に力を与えてきました。CNC機械加工、レーザー加工、研削、研磨、メタライゼーション、ろう付け、および成形における最先端の専門知識により、当社は航空宇宙、エレクトロニクス、エネルギー、医療、および産業分野のお客様に精密セラミック部品を提供してきました。ラピッドプロトタイピングから少量生産まで、性能、品質、信頼性を常にお届けします。