化学、プラスチック、ゴムにおけるアドバンストセラミックスの応用

アドバンスト・セラミックスは、あらゆる分野で必要不可欠な素材となっている。 ケミカル, プラスチックそして ゴム その卓越した技術により、各分野で高い評価を得ている。 耐食性, 耐摩耗性そして 高温安定性.より リアクターライニング 石油化学プラントで セラミックコーティングローラー ポリマー処理ラインにおいて、これらの設計された材料は、装置の寿命を最適化し、プロセス効率を改善し、以下のことを可能にします。 グリーン・マニュファクチャリング.

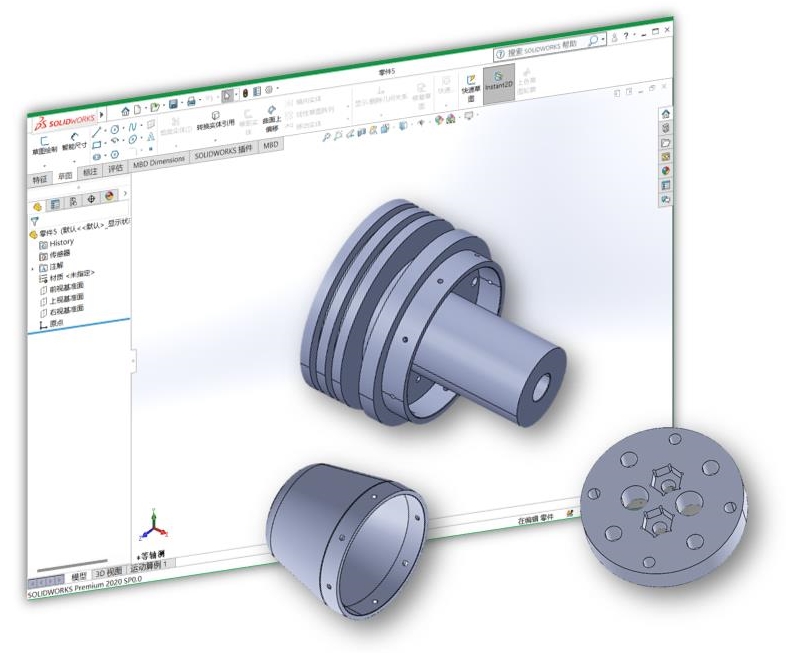

Great Ceramic社は、化学、プラスチック、およびゴム産業向けに特別に設計された精密工学セラミック部品を提供しています。これらのテクニカルセラミックスは、比類のない耐摩耗性、熱安定性、化学的不活性、および電気絶縁性を提供し、上流、中流、および下流の用途に不可欠です。

なぜアドバンスト・セラミックスを使うのか?

アドバンスト・セラミックスは、高純度、制御された微細構造、従来のセラミックスに比べ優れた特性を特徴とする人工材料です。主な特徴は以下の通り:

これらの特性により、アドバンスト・セラミックスは、金属やポリマーが機能しないような役割、特に腐食性、研磨性、高温環境で不可欠なものとなっています。

メリットだ:

主な用途

化学業界

プラスチック産業

ゴム産業

最も一般的なセラミック材料

Great Ceramicでは、アルミナ(Al₂O₃)、炭化ケイ素(SiC)、窒化ケイ素(Si₃N↪N84↩)、酸化ジルコニウム強化アルミナ(ZTA20)などのアドバンストセラミックスを活用することで、化学、プラスチック、ゴム業界のお客様がかつてないレベルの性能、信頼性、持続可能性を達成できるよう支援しています。

| セラミック素材 | 特性と利点 | 代表的なアプリケーション |

|---|---|---|

| アルミナ(Al₂O₃) | 高硬度、耐薬品性に優れ、コストパフォーマンスに優れる。 | シール、ブッシング、ガイド、バルブ |

| ジルコニア (ZrO₂) | 強靭、耐摩耗性、耐腐食性 | ポンプシャフト、プランジャー、粉砕媒体 |

| 炭化ケイ素(SiC) | 超硬度、耐熱衝撃性、優れた耐食性 | ノズル、リアクターライニング、押出工具 |

| 窒化ケイ素 (Si₃N₄) | 軽量、高強度、耐熱衝撃性 | ベアリング、ミキサー、高温バルブ部品 |

| 窒化アルミニウム(AlN) | 高熱伝導性、電気絶縁性 | 高温電子機器、ヒーター、プロセス監視装置 |

| 窒化ホウ素(BN) | 化学的に不活性で、優れた潤滑性と絶縁性 | 潤滑コーティング、絶縁体、るつぼ |

| ZTA(ジルコニア強化アルミナ) | 靭性と硬度のバランス | ダイインサート、ガイド、ウェアプレート |

| MGC(マシナブル・グラス・セラミック) | 機械加工が容易で、断熱性・電気絶縁性に優れている。 | 絶縁部品、スペーサー、カスタムラボ部品 |

グレート・セラミックの実力

Great Ceramicでは、要求の厳しい化学およびプラスチック加工環境に合わせたカスタム精密セラミック部品を提供しています。ジルコニアプランジャーからアルミナノズル、炭化ケイ素耐摩耗ライナーまで、当社の材料と製造能力は、長寿命、精度、および性能を保証します。