業界を超えたグレートセラミックスの用途

アドバンストセラミックスは、高性能で需要の高い用途で比類のないソリューションを提供し、幅広い産業で不可欠なものとなっています。次世代の航空宇宙部品の動力源から、医療用インプラントの信頼性の向上、高効率エレクトロニクスの実現まで、これらの材料は、技術革新と産業の進歩の中核にあります。

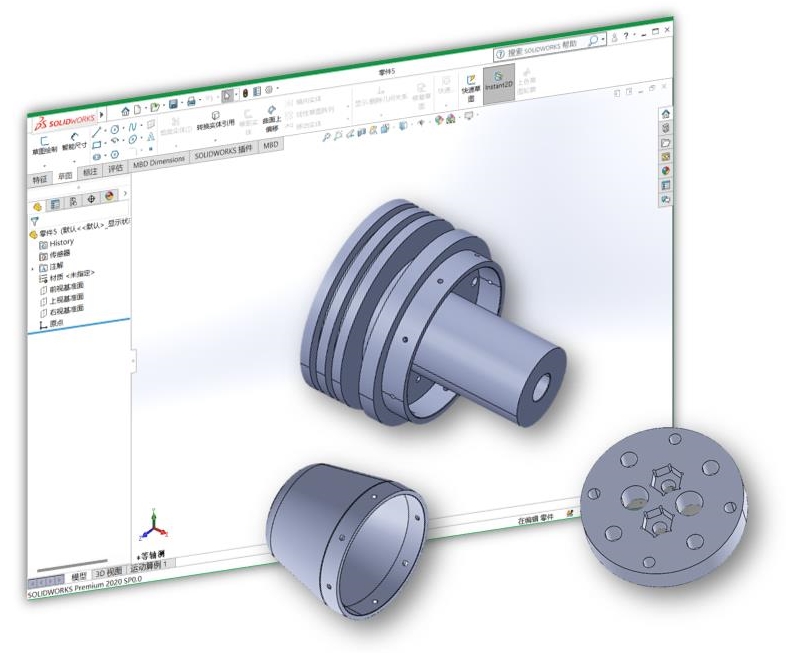

Great Ceramic社では、最も厳しい技術要件を満たす精密設計のセラミック部品および基板を提供することを専門としています。セラミック加工、メタライゼーション、ろう付けサービスにおける当社の専門知識は、製品の信頼性を高め、システム障害を減らし、業務効率を向上させるビジネスを支援します。

業界をリードする素材

Great Ceramicは、お客様の用途に最適な製品を確実に製造できるよう、幅広い先進セラミック材料を製造しています。当社の先端 (技術) セラミック材料は、卓越した性能を提供し、お客様の製品をより軽く、より効率的に、より耐久性のあるものにすると同時に、メンテナンスおよび長期的な運用コストを削減します。

| 素材 | 特徴 | ハイライト | 製品紹介 |

|---|---|---|---|

| アルミナ(Al₂O₃) | 耐摩耗性、絶縁性 | 高性能部品の精密研削 | ダウンロード |

| ジルコニア (ZrO₂) | 強靭、研磨可能、高強度 | 破壊靭性が必要な部品に最適 | ダウンロード |

| 炭化ケイ素(SiC) | 非常に硬く、化学的に安定 | 高温、腐食性環境に最適 | ダウンロード |

| 窒化ケイ素 (Si₃N₄) | 軽量、耐熱衝撃性、高温に強い | 複雑な形状の航空宇宙部品やエンジン部品に適しています。 | ダウンロード |

| 窒化アルミニウム(AlN) | 高熱伝導性、電気絶縁性 | 熱管理部品の精密研削が必要 | ダウンロード |

| ZTA(ジルコニア強化アルミナ) | 靭性、耐摩耗性の向上 | 構造部品用に厳しい公差で加工可能 | – |

| 窒化ホウ素(BN) | 優れた耐熱衝撃性、電気絶縁性、機械加工性 | 成形が容易で、高温・非反応部品に最適 | ダウンロード |

| MGC | 加工が容易で、熱的に安定 | 迅速な試作や複雑な形状に最適 | ダウンロード |

お客様の用途でカスタムセラミック部品が必要な場合、最適な材料と加工方法を選択するお手伝いをいたします。

よくある質問 (FAQ)

先端セラミックス製造のエキスパート

素晴らしいセラミックと提携

精密セラミック部品の信頼できる製造業者として、Great Ceramicはお客様の業界固有のニーズに合わせたソリューションを提供します。当社のサービスには以下が含まれます:

お客様の製品に高度なセラミックソリューションを導入するお手伝いをいたします。