Boron Nitride (BN) is an advanced ceramic material composed of boron (B) and nitrogen (N). Because of its structural similarity to graphite, it is often referred to as "white graphite." As a synthetic compound, boron nitride can exist in several crystalline forms under different conditions, including:

-

Hexagonal Boron Nitride (h-BN): Layered structure with excellent lubricity, high thermal conductivity, and outstanding electrical insulation. This is the most widely used form.

-

Cubic Boron Nitride (c-BN): The second hardest material after diamond, widely applied in cutting tools and wear-resistant coatings.

-

Wurtzite Boron Nitride (w-BN): A rare and ultra-hard crystalline form that may even exceed diamond in hardness under extreme conditions.

-

Amorphous Boron Nitride (a-BN): Often used in coatings and thermal management films due to its good heat conductivity.

Key Properties:

-

High thermal conductivity, superior to most conventional ceramics

-

Excellent electrical insulation, suitable for high-voltage and high-frequency applications

-

Exceptional chemical stability and high-temperature resistance

-

Superior machinability — BN machinable ceramics can be shaped using standard tooling

アプリケーション

Boron nitride is widely used in electronics (heat spreaders, insulators), metallurgy (crucibles, protective tubes), aerospace (thermal protection materials), mechanical engineering (lubricated bearings, seals), and cutting tools (c-BN superhard tools).

As a functional ceramic that combines thermal conductivity, insulation, and high-temperature stability, BN has become a critical material in electronics, energy, aerospace, and advanced manufacturing industries.

Structural Variants of Boron Nitride

六方晶窒化ホウ素(h-BN)

Hexagonal BN, often called "white graphite", has a layered structure similar to graphite. The weak van der Waals forces between layers give h-BN excellent lubricating properties, high chemical stability, and outstanding electrical insulation.

-

How is hexagonal boron nitride h-BN?

h-BN is formed by alternating boron and nitrogen atoms in a hexagonal arrangement, producing a lamellar crystal structure. -

How to make hexagonal boron nitride h-BN?

h-BN can be synthesized using chemical vapor deposition (CVD), high-temperature solid-state reactions, or through high-pressure techniques that stabilize its layered form.

Cubic Boron Nitride (c-BN)

Cubic BN is the second hardest material known after diamond. It has a zinc-blende structure, offering exceptional wear resistance, oxidation resistance, and high thermal stability, making it suitable for cutting and grinding tools.

Wurtzite Boron Nitride (w-BN)

Wurtzite boron nitride (w-BN) is a rare and ultra-hard crystal structure that forms under high temperature and pressure. Theoretically, w-BN exhibits higher hardness than diamond due to bond compression mechanisms. While difficult to produce in large quantities, its potential in extreme mechanical applications continues to attract research interest.

Amorphous Boron Nitride (a-BN)

Boron nitride a-BN lacks a long-range crystal structure, existing in a disordered amorphous phase. This form is often deposited as thin films through techniques such as sputtering and plasma deposition.

-

A notable property is boron nitride a-BN heat conductivity, which makes it attractive for coatings, insulating layers, and dielectric applications in electronics.

Key Properties of BN Boron Nitride

BN offers a unique set of properties that distinguish it from other ceramics:

-

High Thermal Conductivity – h-BN and a-BN effectively transfer heat, making them ideal for substrates and insulating layers in high-power electronics.

-

Excellent Electrical Insulation – despite high thermal conductivity, BN remains an outstanding dielectric material.

-

High Hardness – c-BN and w-BN are among the hardest known materials, outperforming many natural and synthetic ceramics.

-

Chemical Stability – BN resists oxidation and corrosion even at elevated temperatures.

-

Machinability – BN machinable boron nitride ceramic can be processed into complex shapes, enabling custom designs for aerospace, semiconductor, and scientific applications.

The debate over h-BN preparation: laboratory ideals vs. industrial reality

The production of high-quality hexagonal boron nitride (h-BN) has always been a focal point of debate between academia and industry. Currently, two main technical approaches exist:

Vapor deposition can produce high-quality h-BN thin films, but faces challenges such as high costs and difficulty in scalability. In contrast, the precursor method, while more suitable for large-scale production, compromises product purity and crystallinity.

The more heated debate centers on which technical approach will be able to meet the future semiconductor industry's demand for h-BN. Some experts insist that vapor deposition is the only viable path, while others argue that improved precursor methods will become the mainstream.

Amorphous Boron Nitride's Thermal Management Revolution

The emergence of amorphous boron nitride in the field of thermal management has sparked new technical discussions. Conventional wisdom holds that only crystalline materials possess superior thermal conductivity, but a-BN defies this assumption.

Research has shown that a-BN thin films can achieve an in-plane thermal conductivity of up to 2.0 W/mK. While lower than that of crystalline h-BN, it still performs exceptionally well as an ultra-thin dielectric layer. The debate centers on whether a-BN can meet the heat dissipation requirements of future chips fabricated at sub-5nm.

Proponents argue that a-BN's amorphous structure makes it easier to integrate with existing semiconductor processes, while opponents question its long-term thermal stability.

Machinable Boron Nitride Ceramics: A Technological Miracle or a Product of Compromise?

The emergence of machinable boron nitride ceramics has sparked a new technological debate. These materials can be easily cut with standard machining tools, defying the conventional wisdom that ceramics are inherently brittle and hard.

Supporters hailed this as a revolutionary breakthrough in materials design, significantly expanding the application of boron nitride in complex components. Critics, however, pointed out that machinability comes at the expense of some mechanical properties, questioning its reliability in high-stress environments.

The reality is that the successful application of machinable boron nitride ceramics in semiconductor manufacturing, high-temperature furnace linings, and other fields demonstrates the practical value of this balanced design. However, debate remains: Are we overly pursuing machining convenience while neglecting the material's essential properties?

Comparison of Boron Nitride Ceramics with Other Advanced Ceramics

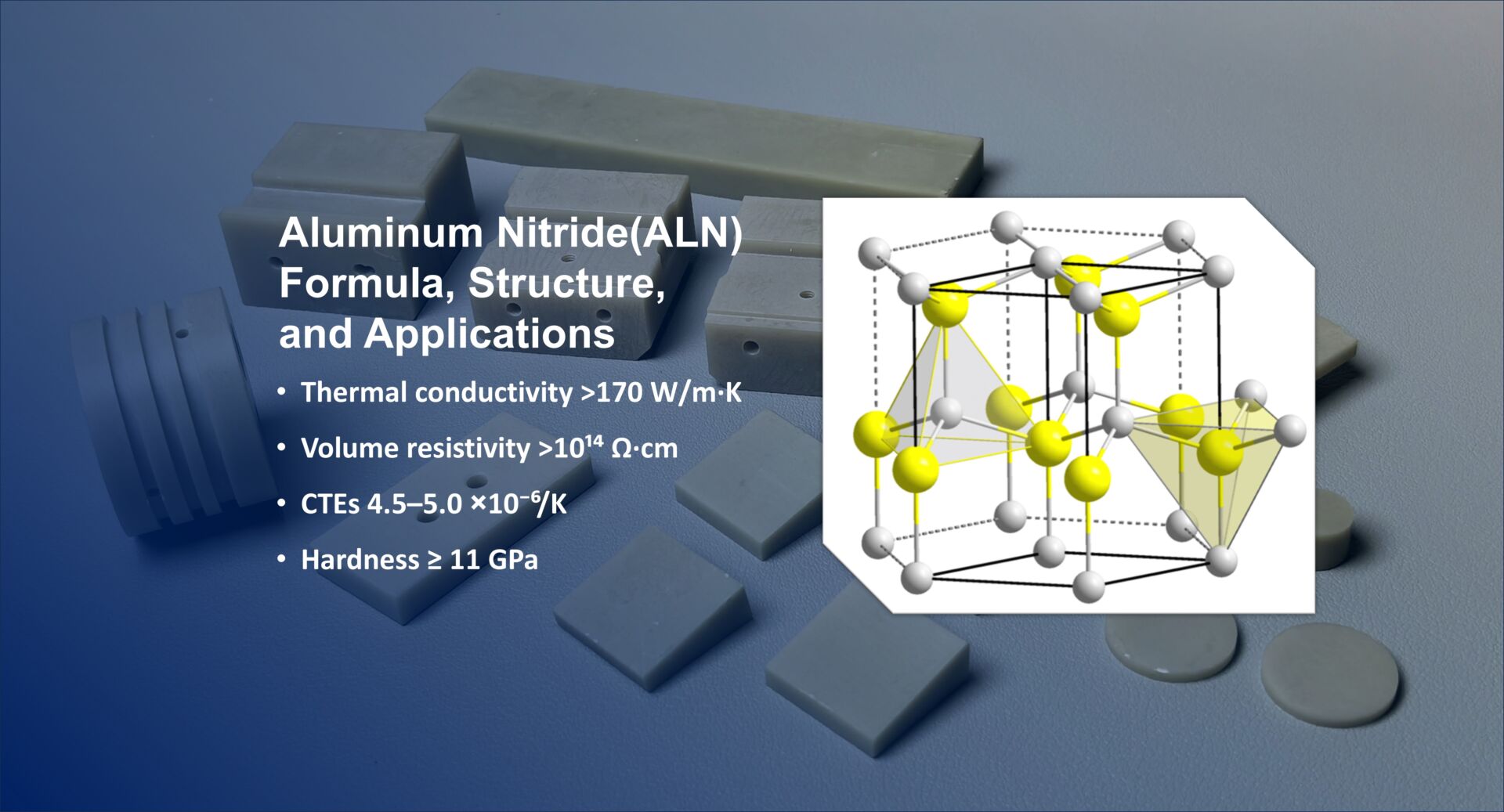

When selecting advanced ceramics for industrial use, it is crucial to compare boron nitride (BN) with other commonly used materials such as alumina (Al₂O₃), zirconia (ZrO₂), silicon nitride (Si₃N₄), and aluminum nitride (AlN). Each material offers unique advantages depending on the application.

| Property / Material | BN (Boron Nitride) | アルミナ(Al₂O₃) | ジルコニア (ZrO₂) | 窒化ケイ素 (Si₃N₄) | 窒化アルミニウム(AlN) |

|---|---|---|---|---|---|

| 熱伝導率 | High (h-BN, a-BN ~200 W/m·K) | Low (~20–30 W/m·K) | Low (~2–3 W/m·K) | Medium (~30 W/m·K) | Very High (~180 W/m·K) |

| 電気絶縁 | 素晴らしい | 素晴らしい | 素晴らしい | グッド | 素晴らしい |

| 加工性 | Easy to machine (BN machinable ceramic) | Hard, requires diamond tooling | Very hard, difficult to machine | Hard, requires advanced tooling | Hard, limited machinability |

| 耐薬品性 | Inert to most molten metals | Stable in oxidizing environments | Resistant to wear and corrosion | Excellent in high-stress conditions | Sensitive to moisture in some cases |

| 硬度 | Moderate (soft compared to ZrO₂/Si₃N₄) | High | Very high | High | ミディアム |

| 高温安定性 | Excellent (>2000°C in inert gas) | Up to ~1600°C | Up to ~1200°C | Excellent (~1400–1600°C under load) | Good (~1200°C) |

| アプリケーション | Heat sinks, crucibles, insulators, aerospace | Substrates, insulators, wear parts | Cutting blades, medical implants | Bearings, turbines, structural parts | Power electronics, LEDs, heat spreaders |

Key Insights for Procurement:

Global Supply and BN Factories in China

With the rising demand for advanced ceramics, boron nitride BN factory in China plays a central role in the global market. Chinese manufacturers offer:

-

Large-scale production of h-BN powders and machinable ceramics.

-

Competitive pricing for BN-based substrates and components.

-

Export supply chains supporting electronics, aerospace, and high-tech industries.

The combination of advanced processing techniques and cost-effective manufacturing makes China one of the leading suppliers of BN ceramics worldwide.

About Great Ceramics – Your Trusted BN Boron Nitride Supplier

At Great Ceramics, we specialize in the production and global supply of BN Boron Nitride materials. As a leading boron nitride BN factory in China, we provide:

-

Hexagonal BN powders and ceramics with excellent lubricating and insulating properties.

-

Amorphous BN (a-BN) products with superior dielectric strength and a-BN heat conductivity.

-

Machinable BN ceramics for aerospace, electronics, and high-temperature applications.

-

Custom BN components designed for specific technical requirements.

With competitive pricing, advanced processing capabilities, and reliable global delivery, Great Ceramics has become a trusted partner for industries requiring high-performance BN materials.

Future Directions and Research

-

2D BN Materials: hexagonal BN nanosheets and films are under investigation for flexible electronics, transparent insulating layers, and spintronics.

-

Hybrid Composites: combining BN with graphene, SiC, or AlN to enhance multifunctional performance.

-

Ultra-Hard Phases: expanding research on scalable synthesis of wurtzite boron nitride w-BN for industrial cutting tools and protective coatings.

FAQ

結論

BN Boron Nitride is a family of advanced ceramics with diverse structures—ranging from lubricating h-BN to ultra-hard w-BN. Its high thermal conductivity, chemical stability, and mechanical strength make it indispensable for modern industry. From machinable boron nitride ceramic components to cutting-edge applications in electronics and aerospace, BN continues to evolve as a material of the future.

As research on how to make hexagonal boron nitride h-BN and scalable production of wurtzite boron nitride w-BN progresses, BN will further solidify its position in the global advanced materials market.