窒化アルミニウム(AlN)-しばしばALNまたはAINと略される-は、アルミニウムと窒素のセラミック化合物である。この二元系窒化物は、六方晶系ウルツ鉱格子(GaNやZnOに類似)で結晶化する。強いAl-N結合と四面体配位により、AlNは超広帯域バンドギャップ(~6.1eV)を持つ電気絶縁体です。主な材料特性には、高密度(~3.26g/cm³unipretec-ceramics.com)、極めて高い硬度(~11GPaビッカース)、卓越した熱伝導性などがあります。

Great Ceramic社は、優れた熱的・電気的特性を持つカスタムAlN基板および部品(プレート、ワッシャー、スペーサーなど)を提供しています。同社のAlNセラミックスは、純度96%以上で、高い熱伝導率(170-200W/mK以上)、非常に低い熱膨張率、高い強度と硬度、優れた電気絶縁性を示します。これらの特性により、AlNは電子パッケージングや熱管理-例えば、高出力LEDモジュール、IGBTやMOSFETパワーモジュール、RF/マイクロ波デバイス、効率的な放熱と電気的絶縁が重要なその他の回路におけるヒートシンクや基板-に理想的な材料となっています。実際、AlN基板の熱伝導率はアルミナ(Al₂O₃)の最大9倍であり、熱膨張係数(~4.6×10-⁶/K)はシリコンに近く、チップパッケージの応力を緩和します。代表的なAlNセラミック部品には、プレート、ロッド、チューブ、ワッシャー、カスタム機械加工部品があり、Great Ceramicでは精密CNC機械加工またはレーザー加工で提供しています。

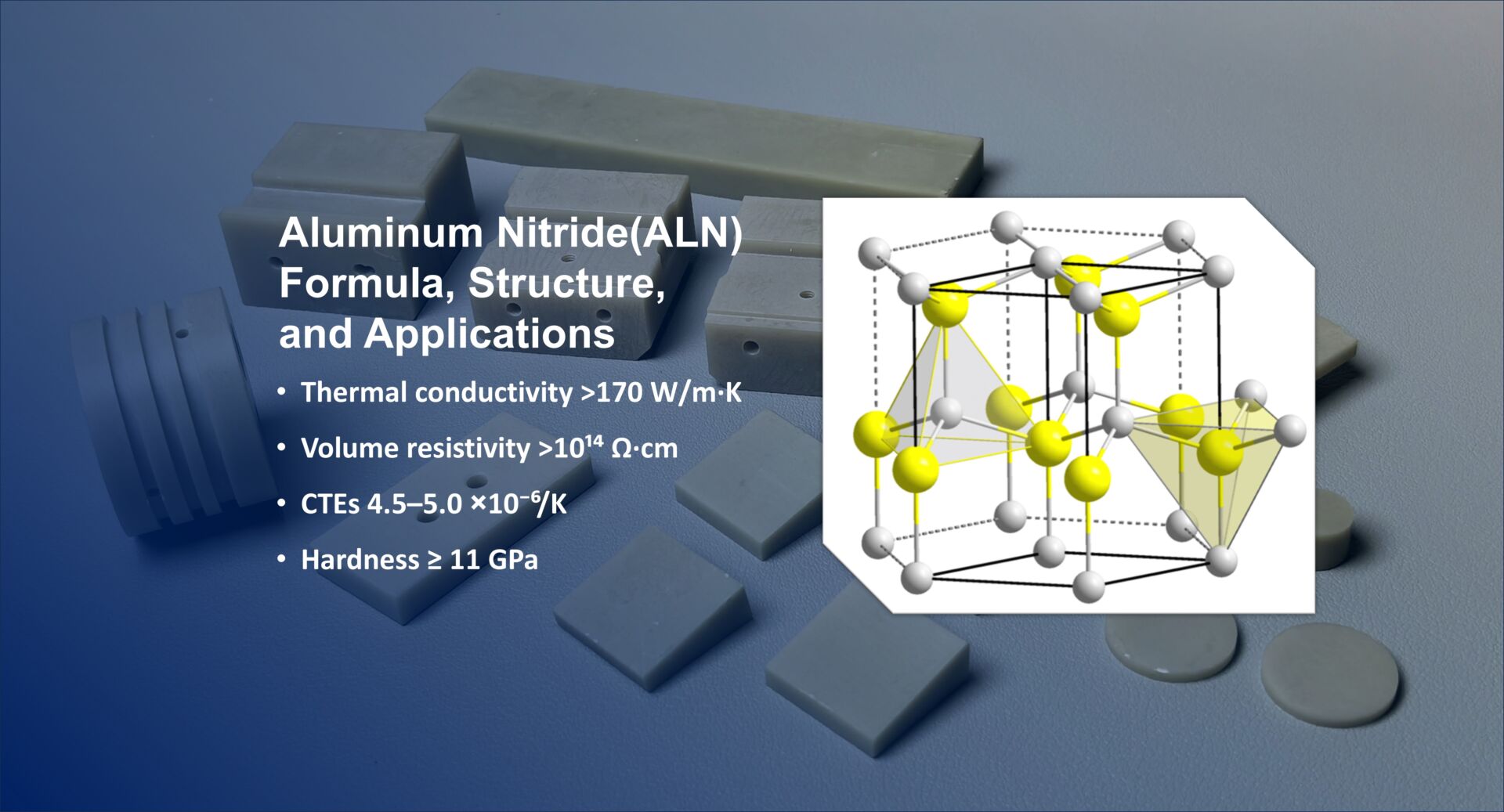

AlNの構造と物性

AlNの六方晶ウルツ鉱構造は、各Al原子に4つの最近接Nを与える(逆も同様)。この強力なイオン/共有結合により、超ワイドバンドギャップ(~6.1eV)半導体となり、高耐圧が得られる。AlNの熱伝導率は、セラミックスの中では例外的に高い(バルクAlNは170~200W/m・K、単結晶は~320W/m・K)。比較のため、AlNの熱伝導率はアルミナの約8倍であり、他のほとんどの技術用セラミックスの熱伝導率をはるかに上回っている。AlNの低熱膨張率(~4.5~5.2×10-⁶/K)は、シリコンの熱膨張率(~2.6×10-⁶/K)に近く、電子機器の熱歪みを最小限に抑えます。硬度も高く(ビッカース~11 GPa)、AlNは化学的に安定しています(酸/塩基や溶融金属に耐性があります)。高熱安定性、高剛性(ヤング率~320GPa)、紫外域での光学的透明性といったこれらの複合特性は、幅広い用途を可能にする。

AlNの産業応用

AlNセラミックスは、熱を効率的に移動させなければならない場所や、高温・高出力での断熱が必要な場所で使用される。主な用途は以下の通りです:

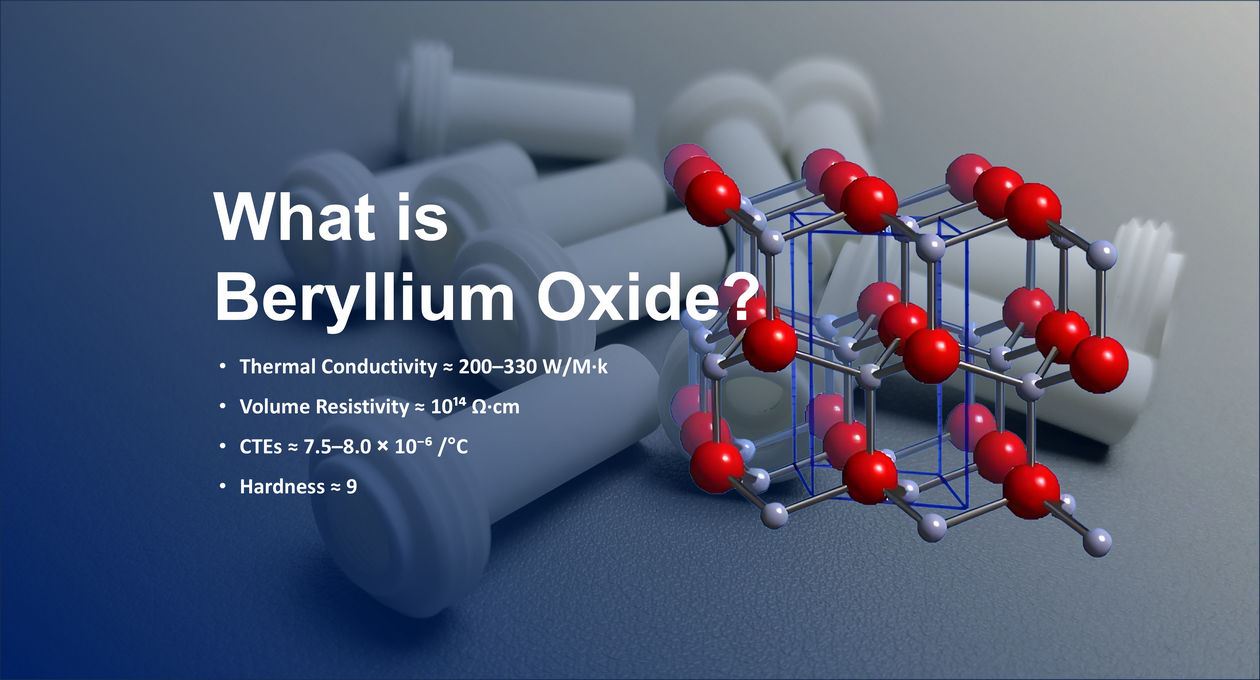

これらのアプリケーションでは、熱管理と電気絶縁のAlN独自の組み合わせが活用されています。多くの場合、アルミナ(Al₂O₃)や酸化ベリリウム(BeO)よりもAlNが選ばれるのは、その優れた熱伝導とシリコンと同様の膨張が理由です。

半導体と先端パッケージングにおけるAlN

AlNは超広帯域バンドギャップ(UWBG)半導体材料として注目を集めている。バンドギャップ≒6eのAlNは、極端な大電力・高周波エレクトロニクスに適している。コーネル大学の研究者は、AlNの「熱伝導性、高耐圧、強い電界耐性」が、次世代のパワー・トランジスタやダイオードに理想的であると指摘している。現在の研究開発(DARPAの資金提供プロジェクトなど)では、電力損失を削減するために、超低オン抵抗のAlNベースのPINダイオードに焦点が当てられている。さらに、AlN基板は、最初の深紫外ダイオード・レーザー(波長 <280 nm) – critical for sterilization and sensing – due to AlN's lattice compatibility with aluminum gallium nitride (AlGaN) layers.

電子パッケージングにおいて、AlNセラミック基板は「ゲームを変える」役割を果たしている。AlNの熱伝導率(150~230W/m・K)はアルミナを大きく上回り、熱抵抗を最小限に抑えてチップから熱を逃がすことができます。その結果、AlN基板は、IGBTモジュール、パワー・コンバータ、および先進的なLEDパッケージで広く使用されています。AlNはまた、その高い熱性能と絶縁性が、高密度でハイパワーなアセンブリの信頼性を向上させるため、先進的なパッケージング技術、例えばファンアウト・ウェハレベル・パッケージや3D積層モジュールでも使用されています。

グレートセラミックのAlN製品とサービス

Great Ceramicは、AlNセラミックおよびカスタム部品の専門メーカーです。当社は、高純度(>96%)窒化アルミニウムセラミック材料を、プレート、基板、チューブ、ロッド、ワッシャー、スペーサー、および完全機械加工部品など、さまざまな形態で提供しています。当社のAlN部品は、厳しい公差およびパワーエレクトロニクス用のオプションの金属化(銅またはDBCコーティングなど)でカスタム設計およびOEM生産が可能です。Great CeramicのAlNセラミックスは、通常、密度~3.3 g/cc、熱伝導率>170 W/m・Kです。当社は、精密レーザー切断および研削を含む、ラピッドプロトタイピングおよび少量生産をサポートしています。当社のALN能力を調査したり、見積もりを依頼したりするには、窒化アルミニウム(AlN)製品ページを参照するか、技術サポートについてお問い合わせください。