Solution pour les céramiques métallisées

Au Grande céramiqueNous sommes spécialisés dans céramiques métallisées des solutions adaptées aux applications industrielles et électroniques de haute performance. Avec une base solide en usinage avancé de la céramiquenous livrons services de métallisation céramique sur mesure qui permettent de réaliser des assemblages céramique-métal robustes, à haute température et hermétiques.

Que votre demande nécessite traversées céramique-métal, emballage électronique sous videou substrats métallisés à haute fiabilitéNos capacités d'ingénierie et de traitement garantissent une qualité constante et des résultats très performants.

Passer à

Introduction | Capacités | Cas | Matériaux | Applications | FAQ

Qu'est-ce que la céramique métallisée ?

Céramiques métallisées représentent une pierre angulaire dans l'histoire moderne de la technologie d'emballage en céramiqueLe dépôt de couches métalliques fonctionnelles sur des surfaces céramiques isolantes permet d'obtenir des joints fiables, très résistants et hermétiques entre des composants céramiques et métalliques. En déposant une couche métallique fonctionnelle sur une surface céramique isolante, nous créons des surfaces qui supportent le brasage de la céramique sur le métal, emballage électronique sous videet connectivité électrique tout en conservant les avantages intrinsèques des céramiques avancées.

Pourquoi les céramiques métallisées ?

Les céramiques telles que alumine (Al₂O₃), nitrure d'aluminium (AlN), zircone (ZrO₂)et nitrure de silicium (Si₃N₄) possèdent une excellente stabilité thermique, une résistance à l'usure et une isolation électrique. Toutefois, il est difficile de les coller directement aux métaux en raison d'une mauvaise mouillabilité et d'une dilatation thermique inadaptée.

Technologie de métallisation surmonte ces limitations en formant une liaison métallurgique entre la céramique et le métal par le biais de diverses méthodes - permettant :

Ce que nous faisons : Capacités de métallisation des céramiques

Great Ceramic fournit des céramiques métallisées de haute fiabilité en utilisant des revêtements Mo/Mn et Mo/Mn/W exclusifs, permettant un brasage précis et hermétique de la céramique sur le métal. Grâce au placage interne, à l'usinage à tolérances serrées et aux tests complets de résistance et d'intégrité des joints, nous fournissons des solutions personnalisées pour les applications médicales, électroniques, d'alimentation et de capteurs. Les indicateurs de performance de la métallisation sont les suivants :

Techniques de métallisation proposées

Nos experts travaillent avec vous pour sélectionner les meilleurs matériaux et processus de métallisation afin d'obtenir des joints brasés fiables et très résistants, même dans des géométries difficiles.

Méthodes d'application de la métallisation

Nous choisirons la méthode appropriée en fonction de la structure du produit (cylindrique, plat, trou intérieur) ainsi que des exigences en matière de lots et de précision.

Boîtier en céramique métallisée

Nous produisons sur mesure des céramiques d'alumine métallisées pour les traversées sous ultravide, les brides d'isolateur sous vide, les tubes de décharge de gaz, les tubes à grille, les disjoncteurs sous vide, les condensateurs sous vide et d'autres applications similaires, selon les dessins et les exigences du client.

Isolateur en céramique métallisée

Composant céramique sous vide

Isolateur en céramique métallisée

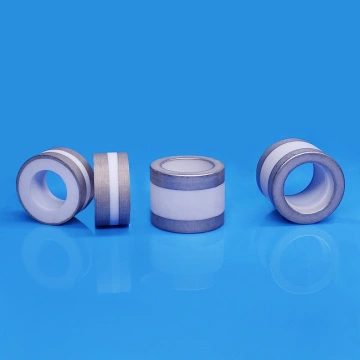

Bague en céramique métallisée

Matériaux céramiques métallisés en option

Nous proposons une large gamme de composants en céramique d'alumine métallisée de haute pureté (95%~99,7%) pour la métallisation en couche épaisse de molybdène (Mo-Mn) et de tungstène (W). Les principales méthodes de métallisation utilisées sont la sérigraphie ou la pulvérisation sous vide, suivies d'un dépôt électrolytique ou chimique sur la surface métallisée avec du nickel, de l'or, de l'argent ou de l'étain. De cette manière, les céramiques peuvent être soudées avec du cuivre sans oxygène, du Kovar, de l'acier inoxydable et d'autres alliages. Les paramètres du matériau sont les suivants :

| Titre du projet | Unité | 96% Al2O3 | 97% Al2O3 | 99% Al2O3 | 99,6% Al2O3 |

| Teneur en alumine | % | Al2O3≧95% | Al2O3≧97% | Al2O3≧99% | Al2O3≧99.6% |

| Gamme de tailles | mm | 0.5-500 | 0.5-500 | 0.5-500 | 0.5-500 |

| Précision maximale | mm | 0.01 | 0.01 | 0.01 | 0.01 |

| Densité apparente | g/cm3 | ≧3.67 | ≧3.70 | ≧3.85 | ≧3.90 |

| Résistance à la flexion | MPa (25℃) | ≧300 | ≧300 | ≧350 | ≧400 |

| Résistance à la compression | GPa (25℃) | ≧1.8 | ≧1.8 | ≧2.0 | ≧2.3 |

| Conductivité thermique | W/m.K | 10-20 | 10-20 | 15-21 | 15-21 |

| Coefficient moyen de dilatation linéaire | /℃ (20~500℃) | 7.36×10-6 | 6.9×10-6 | 6.9×10-6 | 6.9×10-6 |

| Constante diélectrique | 1MHz (20℃) | 9.1 | 9.5 | 9.8 | 10 |

| Valeur de la tangente de perte diélectrique | 1MHz (20℃) | ≦4×10-4 | ≦3×10-4 | ≦2×10-4 | ≦2×10-4 |

| Résistivité volumique | Ω.cm (100℃) | ≧1×1014 | ≧1×1014 | ≧1×1014 | ≧1×1014 |

| Résistance à la rupture en courant continu | KV/mm | ≧30 | ≧35 | ≧25 | ≧25 |

| Résistance aux chocs thermiques | ℃ | 20~800 | 20~800 | 20~800 | 20~800 |

| Température maximale de fonctionnement | ℃ | ≦1300 | ≦1400 | ≦1500 | ≦1500 |

| Résistance aux acides | Général | Adapté | Premier ordre | Premier ordre | |

| Résistance aux alcalis | Général | Adapté | Adapté | Premier ordre | |

| Facilité de métallisation | Facile | Difficulté normale | Difficulté moyenne | Très difficile | |

| Étanchéité à l'air | Pa-m3/s | ≦1×10-11 | ≦1×10-11 | ≦1×10-10 | ≦1×10-9 |

| Résistance moyenne à la traction | MPa | 130 | 130 | 130 | 130 |

Note : Chaque lot peut être différent, à titre de référence uniquement.

Note : Veuillez le visualiser sur votre ordinateur.

Applications des céramiques métallisées

Foire aux questions (FAQ)

Personnalisez vos pièces en céramique métallisée

Avec plus d'une décennie d'expérience dans la fabrication de céramiques de pointe, Great Ceramic comprend que le succès des céramiques métallisées repose sur l'ingénierie des interfaces, la compatibilité des matériaux et des tolérances serrées. Chaque étape de notre processus est personnalisée en fonction de votre conception, de votre environnement et de votre méthode d'assemblage.

Que vous construisiez un prototype unique ou que vous prépariez une production à grande échelle, nous prenons en charge des quantités de commande flexibles et nous servons des clients en Europe, en Amérique du Nord et en Asie.