Applications des céramiques avancées dans les machines industrielles

Dans le paysage actuel de la fabrication à haute performance, les machines industrielles évoluent rapidement pour répondre aux exigences d'efficacité, de précision et de durabilité. Les céramiques avancées, également connues sous le nom de céramiques techniques, sont devenues un élément clé de cette transformation. Grâce à leur combinaison unique de résistance mécanique, de stabilité thermique, de résistance chimique et de résistance à l'usure, ces matériaux sont largement adoptés dans un large éventail d'applications de machines industrielles.

Great Ceramic fournit des composants céramiques avancés hautement personnalisés. Ces céramiques techniques offrent une résistance à l'usure, une stabilité thermique, une inertie chimique et une isolation électrique inégalées, ce qui permet aux équipements mécaniques de bénéficier de performances, d'une durabilité et d'une précision inégalées dans l'industrie.

L'importance des céramiques avancées dans les machines industrielles

Les céramiques avancées sont des matériaux inorganiques non métalliques qui sont conçu pour des performances mécaniques, thermiques, chimiques et électriques. Leurs propriétés exceptionnelles les rendent idéales pour les machines modernes soumises à de fortes contraintes, à des frottements et à des fluctuations de température. Ces propriétés réduisent les temps d'arrêt des machines, prolongent leur durée de vie et améliorent leur efficacité énergétique, ce qui fait que les céramiques techniques sont largement utilisées dans la mécanique de précision et l'industrie lourde.

Avantages par rapport aux matériaux traditionnels

| Propriété | Céramique avancée | Métaux | Polymères |

|---|---|---|---|

| Dureté | ★★★★★ | ★★ | ★ |

| Résistance à la corrosion | ★★★★★ | ★★ | ★★★ |

| Résistance à la température | ★★★★★ | ★★ | ★ |

| Résistance à l'usure | ★★★★★ | ★★ | ★ |

| Isolation électrique | ★★★★★ | ★ | ★★★ |

| Conductivité thermique (AlN/BeO) | ★★★★★ | ★★★★ | ★ |

Principaux avantages de l'utilisation des céramiques de pointe dans les machines industrielles :

Principaux matériaux céramiques avancés

Chez Great Ceramic, nous aidons nos clients à atteindre des niveaux de performance, de fiabilité et de durabilité sans précédent en leur proposant une large gamme de céramiques avancées aux propriétés exceptionnelles.

| Matériau céramique | Propriétés et avantages | Applications typiques (équipement mécanique) |

|---|---|---|

| Alumine (Al₂O₃) | Dureté élevée, résistance à l'usure, stabilité chimique | Garnitures mécaniques, bagues résistantes à l'usure, rails de guidage, composants de vannes |

| Zircone (ZrO₂) | Ténacité élevée, résistance aux chocs, excellente finition de surface | Arbres de pompe, manchons, bagues d'usure, composants coulissants de précision |

| Carbure de silicium (SiC) | Dureté extrême, excellente résistance thermique et à la corrosion | Garnitures mécaniques, échangeurs de chaleur, buses, rouleaux de précision |

| Nitrure de silicium (Si₃N₄) | Légèreté, haute résistance, résistance aux chocs thermiques | Roulements à billes, rotors de turbocompresseurs, composants de broches, plaques d'usure |

| Nitrure d'aluminium (AlN) | Conductivité thermique élevée, isolation électrique | Dissipateurs de chaleur dans les moteurs, isolateurs haute fréquence |

| Nitrure de bore (BN) | Lubrification solide, inertie chimique, stabilité thermique | Paliers secs, pièces de lubrification à haute température, tampons isolants |

| ZTA (alumine durcie à la zircone) | Robustesse et dureté, résistance accrue à l'usure | Supports d'outils de coupe, pièces de piston, composants de guidage résistant à l'usure |

| MGC (vitrocéramique usinable) | Facile à usiner, excellente isolation diélectrique et thermique | Pièces mécaniques de précision, supports sur mesure, isolateurs électriques |

Applications clés

Les capacités de Great Ceramic

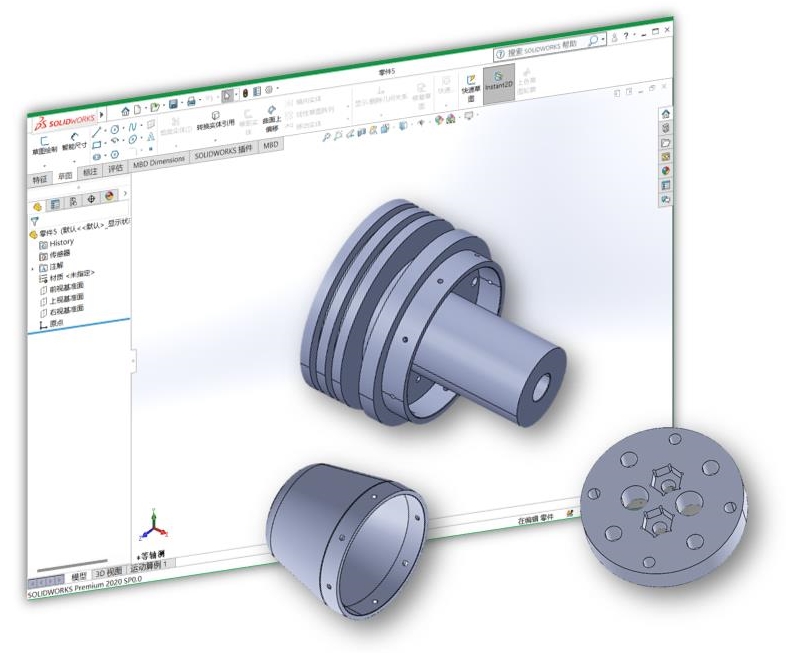

Chez Great Ceramic, nous sommes spécialisés dans les domaines suivants l'usinage sur mesure de composants céramiques avancés. Nos services de fabrication de précision garantissent que chaque pièce répond aux spécifications exactes de la conception, avec des tolérances serrées et des finitions lisses. Nous offrons :

Produits pertinents

Foire aux questions (FAQ)

Pourquoi choisir Great Ceramic pour les applications ?

Que vous souhaitiez optimiser votre ligne de production ou développer un équipement de nouvelle génération, Great Ceramic est votre partenaire de confiance pour la fourniture de solutions céramiques de haute performance.