Solution de métallisation céramique et de brasage métallique

Au Grande céramiqueNous fournissons services professionnels de métallisation et de brasage de surfaces céramiques pour les industries exigeantes telles que l'aérospatiale, l'électronique de puissance, les systèmes à vide, les appareils médicaux et la fabrication de semi-conducteurs.

Combinant une expertise approfondie dans les domaines suivants céramique technique, brasage de précisionet conception d'un joint hermétique céramique-métalDans le cadre de notre programme de recherche, nous aidons nos clients à créer des assemblages fiables et performants qui fonctionnent dans des environnements extrêmes.

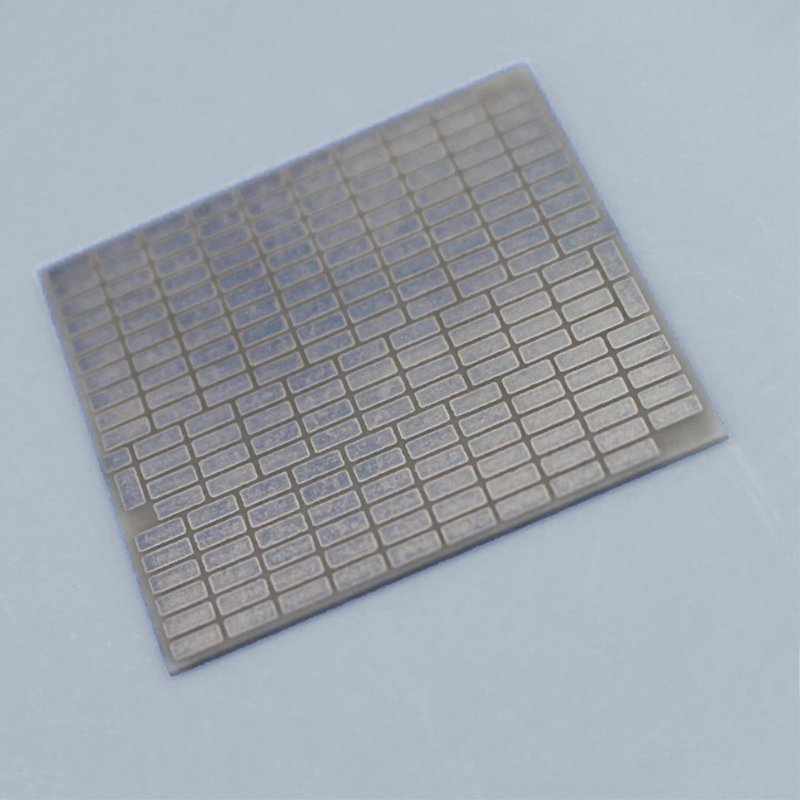

Métallisation céramique est le processus d'application d'une couche métallique conductrice sur la surface des composants céramiques, ce qui permet de les souder, de les braser ou de les relier électriquement à des métaux. Ce processus est essentiel pour la production de joints céramique-métal dans les systèmes à vide, les appareils à haute fréquence et les assemblages d'isolation électrique.

Chez Great Ceramic, nous proposons plusieurs options de métallisation :

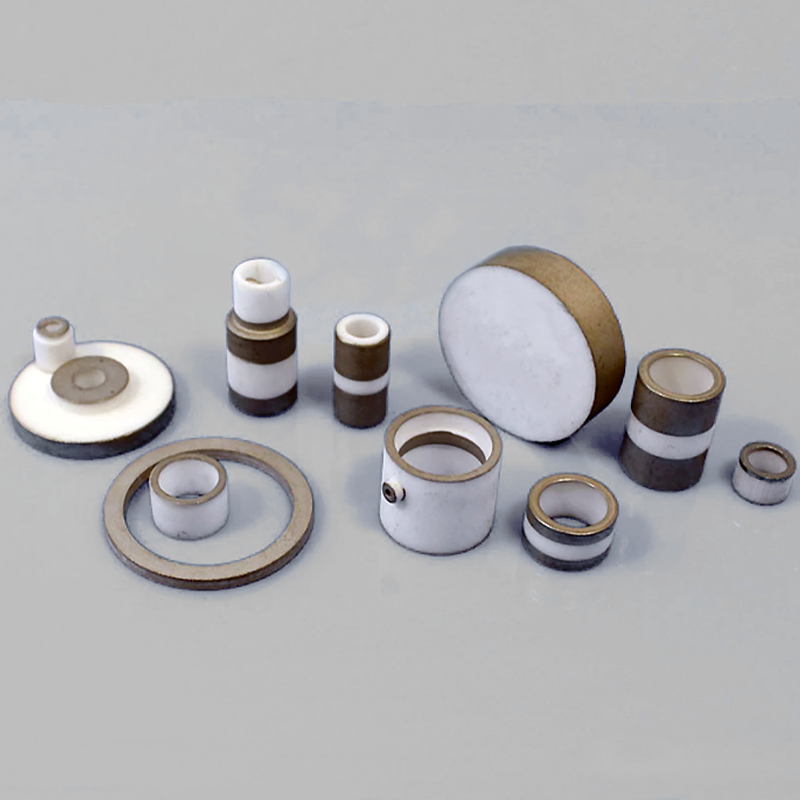

Composants en céramique métallisée que nous fournissons

Isolateur en céramique métallisée

Convient aux fenêtres RF, aux systèmes laser et aux boîtiers de capteurs

Composant céramique sous vide

Adaptée à des exigences mécaniques, électriques ou environnementales spécifiques

Tubes en céramique métallisée

Utilisé dans les tubes électroniques, les thermocouples et l'isolation

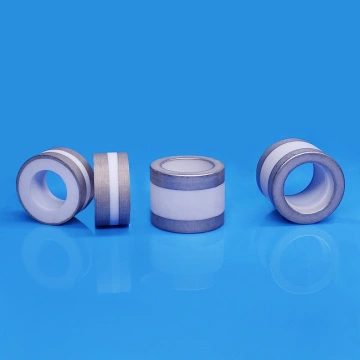

Bague en céramique métallisée

Traversées hermétiques pour dispositifs de vide et de puissance

Toutes les couches métallisées sont contrôlées au niveau de l'adhérence, de l'épaisseur, de la continuité et de la qualité de la surface. Les couches plaquées sont testées pour la soudabilité et la résistance à la corrosion.

Une fois métallisées, les pièces en céramique sont brasées à des métaux tels que le kovar, le titane ou l'acier inoxydable à l'aide de techniques de brasage à haute température. Cela permet de créer des assemblages céramique-métal présentant une étanchéité au gaz et une fiabilité mécanique supérieures.

Great Ceramic peut fournir des composants techniques en céramique brasée pour répondre aux exigences spécifiques des clients. De nombreuses pièces que nous fournissons sont complexes, conçues selon des spécifications strictes ou utilisées dans des applications critiques particulièrement exigeantes.

Caractéristiques du brasage céramique

Le produit adopte le matériau Kovar ou le cuivre exempt d'oxygène dont le coefficient de dilatation linéaire est similaire à celui des céramiques, afin de réaliser le scellement céramique-métal par brasage. Il permet de réaliser une connexion étanche à l'air entre les pièces en céramique et les pièces structurelles en métal. Cette structure d'étanchéité céramique-métal présente les caractéristiques suivantes : force d'étanchéité élevée, bonne étanchéité à l'air et grande fiabilité.

Applications de brasage et d'étanchéité céramique

Utilisé dans les tubes de commutation à vide pour l'énergie électrique et l'électronique, divers klystrons, tubes à ondes progressives, tubes à micro-ondes, magnétrons, thyratrons, déclencheurs, jauges à vide, dispositifs de vision nocturne à micro-ondes et autres industries connexes d'isolation sous vide. La température d'utilisation générale ne dépasse pas 700°C.

Applications des céramiques métallisées et des assemblages brasés

Notre céramiques métallisées et composants brasés sont largement utilisés dans tous les secteurs d'activité pour les tâches critiques qui requièrent des herméticité, isolation électrique, conductivité thermiqueet résistance mécanique.