Prototypage rapide de céramiques et fabrication en petites séries

Great Ceramic propose des services de prototypage rapide de céramiques sur mesure et de fabrication en petites séries pour une large gamme de céramiques techniques. Grâce à une précision de pointe dans l'usinage CNC, la découpe laser à impulsions ultra-courtes, le meulage/polissage au diamant, la métallisation et le brasage céramique-métal, et le formage de la céramique, nous prenons en charge les conceptions avancées, du prototype à la production à petite échelle.

Pourquoi choisir Great Ceramic ?

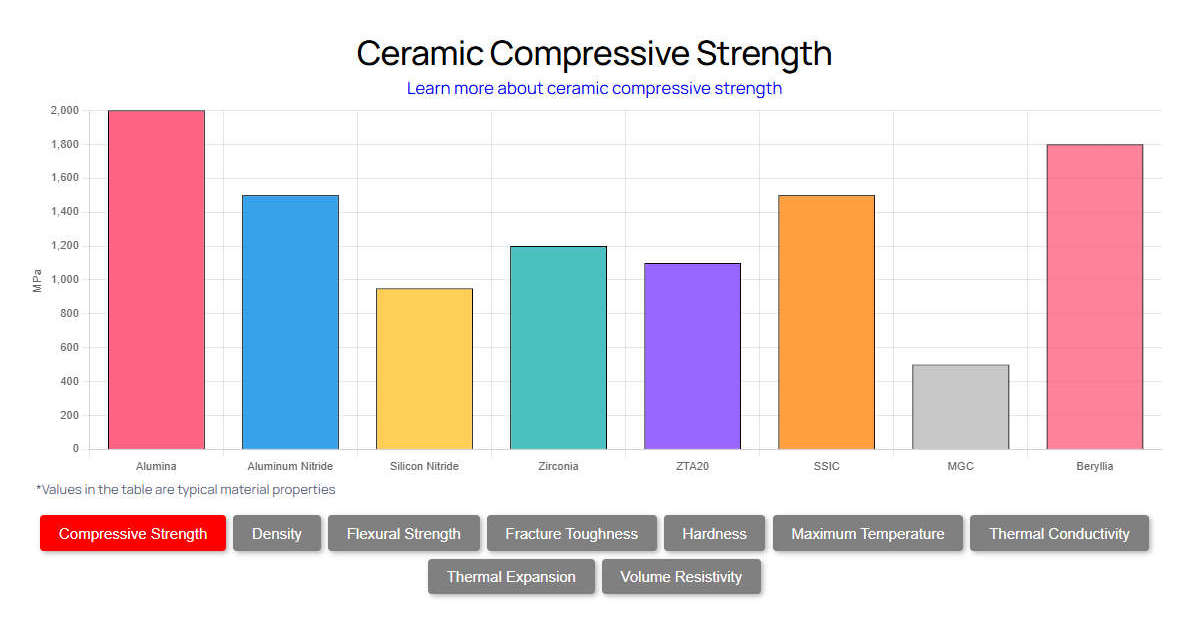

Matériaux céramiques experts

Nous travaillons avec une gamme étendue de céramiques techniques - alumine (Al₂O₃), zircone (ZrO₂, ZTA), nitrure de silicium (Si₃N₄), carbure de silicium (SiC), nitrure d'aluminium (AlN), nitrure de bore (BN), oxyde de béryllium (BeO) et céramique de verre usinable (MGC) - fournies sous des formes allant des poudres aux produits finis, Nitrure d'aluminium (AlN), Nitrure de bore (BN), Oxyde de béryllium (BeO), et Céramique de verre usinable (MGC) - fournis sous des formes allant des poudres aux composants finis.

Capacités de fabrication avancées

Une qualité et une assistance de confiance

Notre flux de travail complet

Veuillez fournir autant d'informations que possible sur les pièces et vos besoins.

Nous respectons la vie privée de nos clients et sommes heureux de travailler dans le cadre d'accords de confidentialité si nécessaire.

Sélection des matériaux et optimisation de la conception

Nous fournissons des conseils d'experts sur la sélection du matériau céramique optimal et sur l'affinement de la conception de votre pièce en vue de sa fabrication :

Une fois les ajustements de conception convenus, nous finalisons les recommandations concernant les matériaux et confirmons la possibilité de fabrication.

Devis

Nous fournirons un devis très compétitif basé sur la conception finale et la méthode de fabrication de la pièce, y compris :

Rapide et clair, notre devis garantit l'absence de coûts cachés ou de surprises.

Production

Une fois la commande passée, votre produit sera fabriqué dans le cadre de notre système strict de contrôle de la qualité.

Principaux procédés de fabrication

- configuration des matériaux

- Granulation par pulvérisation

- Pressage à sec

- Pressage isostatique

- Moulage par injection

- Moulage moulage

- Pressage isostatique à chaud

- Moulage par extrusion

- Frittage

- Pressage à chaud frittage

- Usinage CNC

- Broyage

- Polissage

- Découpe au laser

- Métallisation de surface

- Soudage

- ISO9001:2016

- Inspection stricte réussie

- Divers équipements d'essai

prototypage rapide de céramiques

Nous procédons à l'usinage CNC de précision, au meulage/polissage, au traitement au laser et à d'autres procédés, et nous effectuons l'inspection. Délai de livraison typique : 15-30 jours, en fonction de la quantité et de la complexité.

Livraison

Les pièces finies sont soigneusement inspectées, emballées et expédiées. Nous proposons des options d'expédition à l'échelle mondiale afin de garantir une livraison sans heurts qui réponde à vos attentes en termes de délais et de qualité.

Principaux matériaux que nous traitons

| Matériau | Points forts | Applications populaires |

|---|---|---|

| Alumine (Al₂O₃) | Dureté élevée, excellente isolation | Isolants, substrats électroniques |

| Zircone (ZrO₂ / ZTA) | Ténacité élevée, résistance à l'usure | Composants structurels, boîtiers |

| Nitrure de silicium (Si₃N₄) | Résistance aux chocs thermiques, haute résistance | Roulements, pièces de moteur, creusets |

| Carbure de silicium (SiC) | Ultra-dur, résistance aux produits chimiques | Pièces pour environnements corrosifs et à haute température |

| Nitrure d'aluminium (AlN) | Conductivité thermique élevée, isolation | Gestion thermique, outils pour semi-conducteurs |

| Nitrure de bore (BN) | Lubrifiant sec, isolation haute température | Pièces de roulement et d'isolation à haute température |

| Oxyde de béryllium (BeO) | Caractéristiques thermiques et électriques exceptionnelles | Électronique RF, diffuseurs de chaleur |

| Verre usinable Céramique | Facile à usiner, idéal pour le prototypage | Prototypage de pièces structurelles complexes |

Questions fréquemment posées

Partenaire de confiance pour les céramiques techniques

Depuis 2013, Great Ceramic permet aux innovateurs mondiaux de bénéficier de solutions céramiques avancées. Grâce à notre expertise de pointe en matière d'usinage CNC, de traitement laser, de meulage, de polissage, de métallisation, de brasage et de formage, nous avons équipé nos clients des secteurs de l'aérospatiale, de l'électronique, de l'énergie, de la médecine et de l'industrie avec des pièces céramiques de précision. Du prototypage rapide à la production en petites séries, nous offrons performance, qualité et fiabilité, à chaque fois.