Prépolissage et polissage de la céramique

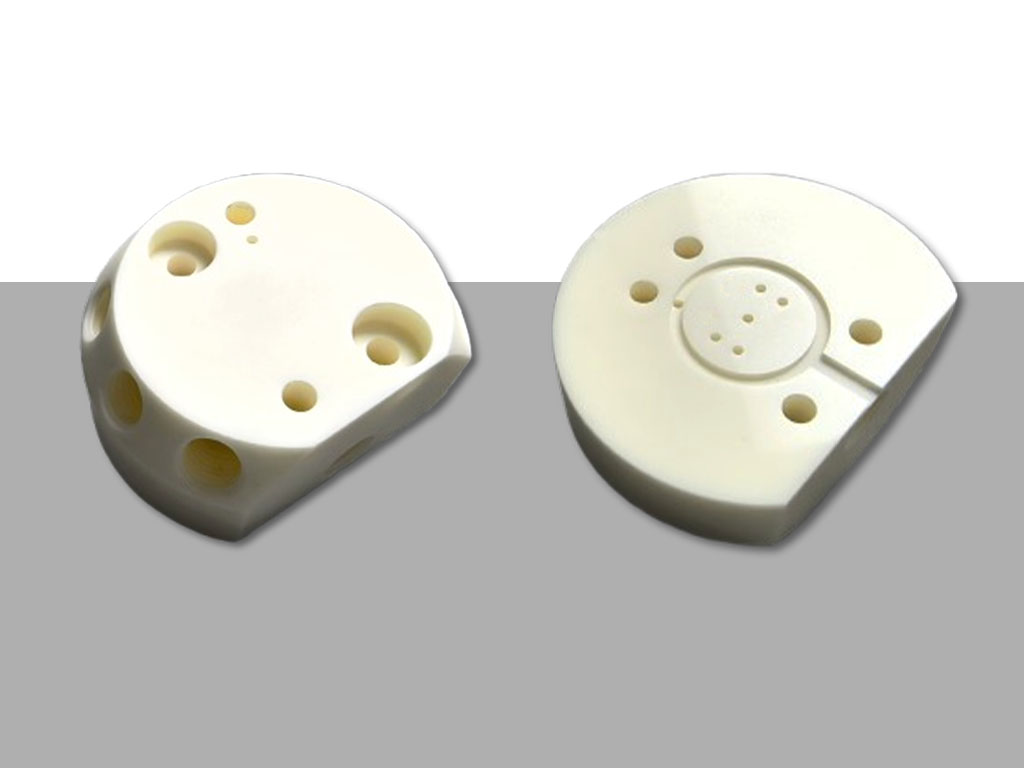

Chez Great Ceramic, nous offrons des services avancés de rectification et de polissage de la céramique adaptés aux applications de haute performance dans les domaines de l'électronique, de la médecine, de l'aérospatiale, etc. Notre équipe d'experts est spécialisée dans l'usinage de la céramique, la finition de surface de précision et le traitement de la céramique après cuisson, afin de garantir que chaque composant présente des tolérances serrées, une qualité de surface irréprochable et une fiabilité fonctionnelle supérieure.

Qu'il s'agisse de fabriquer des arbres en zircone, des isolateurs en alumine ou des boîtiers en céramique personnalisés, nous sommes votre partenaire pour une qualité constante et des délais d'exécution compétitifs.

Pourquoi le prépolissage et le polissage des céramiques sont-ils essentiels ?

Contrairement aux matériaux traditionnels, les céramiques techniques sont extrêmement dures, chimiquement inertes et thermiquement stables, mais aussi fragiles et difficiles à usiner. C'est pourquoi des techniques de meulage et de polissage avancées sont nécessaires pour :

Nous traitons à la fois des pièces céramiques en pâte verte (précuites) et frittées (postcuites) avec une perte de matériau minimale et une qualité de finition maximale.

Matériaux que nous traitons

| Matériau | Points forts | Applications populaires |

|---|---|---|

| Alumine (Al₂O₃) | Dureté élevée, excellente isolation | Isolants, substrats électroniques |

| Zircone (ZrO₂ / ZTA) | Ténacité élevée, résistance à l'usure | Composants structurels, boîtiers |

| Nitrure de silicium (Si₃N₄) | Résistance aux chocs thermiques, haute résistance | Roulements, pièces de moteur, creusets |

| Carbure de silicium (SiC) | Ultra-dur, résistance aux produits chimiques | Pièces pour environnements corrosifs et à haute température |

| Nitrure d'aluminium (AlN) | Conductivité thermique élevée, isolation | Gestion thermique, outils pour semi-conducteurs |

| Nitrure de bore (BN) | Lubrifiant sec, isolation haute température | Pièces de roulement et d'isolation à haute température |

| Oxyde de béryllium (BeO) | Caractéristiques thermiques et électriques exceptionnelles | Électronique RF, diffuseurs de chaleur |

| Verre usinable Céramique | Facile à usiner, idéal pour le prototypage | Prototypage de pièces structurelles complexes |

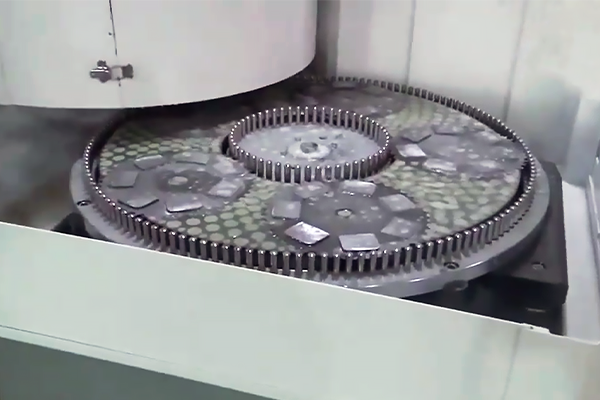

Nos capacités d'usinage et de polissage de la céramique

| Capacité | Fonctionnalité | Tolérance typique | Finition de la surface |

|---|---|---|---|

| Meulage et polissage de surface | Contrôle de la planéité et du parallélisme au micron près

Idéal pour les plaquettes en céramique, les plaques, les isolateurs thermiques |

±0,002 mm | Ra0.02 μm |

| Rectification cylindrique et ID/OD |

Finition de précision des diamètres extérieur et intérieur Utilisé pour les arbres, les manchons, les pistons et les tiges |

±0,002 mm | Ra0.02 μm |

| Meulage et polissage sans centre |

Contrôle à haut débit du diamètre des barres de céramique Excellente répétabilité et efficacité de la production |

±0,001 mm | Ra<0.02 μm |

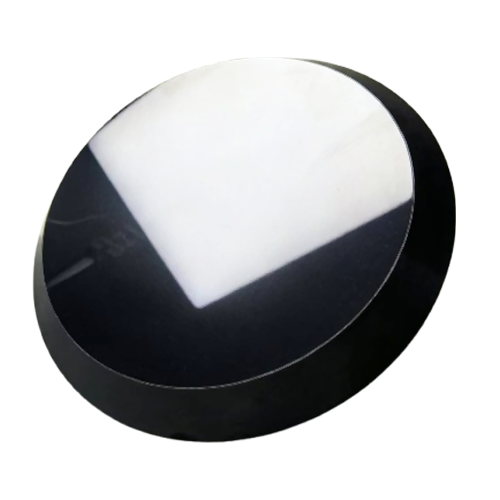

| Meulage fin et rodage |

Tolérance sub-micronique et ultra-planéité Parfait pour le collage de surfaces, de fenêtres optiques et de bagues d'étanchéité |

±0,001 mm | Ra<0.02 μm |

Pourquoi choisir Great Ceramic ?

Nous sommes plus qu'un simple fournisseur de services d'usinage - nous sommes votre partenaire de confiance pour la fabrication de pièces céramiques de pointe. Voici ce qui nous distingue :

Cas d'utilisation des clients

Questions fréquemment posées

Prêt à améliorer vos composants céramiques ?

Que vous développiez des produits électroniques de nouvelle génération, des appareils médicaux de précision ou des isolants de qualité aérospatiale, Great Ceramic est votre partenaire de confiance pour le prépolissage et le polissage des céramiques de pointe.