Applications des céramiques avancées dans les secteurs des semi-conducteurs et de l'électronique

L'industrie des semi-conducteurs et des composants électroniques exige des matériaux capables de fonctionner de manière fiable dans des conditions extrêmes : températures élevées, cycles thermiques rapides, tensions élevées et environnements de fabrication ultra-propres. Céramique avancée sont devenus indispensables dans ce domaine en raison de leur combinaison exceptionnelle de résistance mécanique, d'isolation électrique, de stabilité thermique et d'inertie chimique. Des matériaux tels que alumine (Al₂O₃), nitrure d'aluminium (AlN), nitrure de silicium (Si₃N₄), zircone (ZrO₂), oxyde de béryllium (BeO)et nitrure de bore (BN) sont largement utilisés dans les équipements de traitement des semi-conducteurs, les emballages microélectroniques et les appareils électroniques à haute performance.

Principaux avantages des céramiques avancées pour les applications dans le domaine des semi-conducteurs et de l'électronique

bénéfice :

Matériaux clés dans les applications des semi-conducteurs et de l'électronique

Chez Great Ceramic, nous nous engageons à faire progresser l'application des céramiques de haute performance dans les industries des semi-conducteurs et de l'électronique, en aidant nos clients à atteindre des niveaux de performance, de fiabilité et de durabilité sans précédent.

| Matériau | Propriétés principales | Applications typiques |

|---|---|---|

| Alumine (Al₂O₃) | Economique, bonne isolation, conductivité thermique modérée | Substrats pour LED, boîtiers multicouches, circuits imprimés en céramique |

| Nitrure d'aluminium (AlN) | Conductivité thermique élevée, isolation électrique, compatibilité CTE avec Si | Substrats pour modules de puissance, répartiteurs de chaleur pour dispositifs RF |

| Nitrure de silicium (Si₃N₄) | Grande résistance à la rupture, résistance aux chocs thermiques | Bras de manutention de plaquettes, substrats pour l'électronique de puissance |

| Carbure de silicium (SiC) | Haute résistance, résistance à la corrosion, stabilité thermique | Composants de chambres CVD, revêtements de fours de diffusion |

| Nitrure de bore (BN) | Conducteur thermique + isolant électrique, usinable | Dissipateurs thermiques pour dispositifs RF/micro-ondes, couches d'interface |

| Vitrocéramique usinable (MGC) | Usinage de précision facile, stable jusqu'à 1000°C | Pièces de prototypage, composants de précision en petites séries |

| ZTA (alumine durcie à la zircone) | Haute résistance à l'usure, meilleure ténacité à la rupture | Guides de précision, outils de manipulation des semi-conducteurs |

Avantages en termes de performances par rapport aux métaux et aux plastiques

| Propriété | Céramique avancée | Métaux | Plastiques |

|---|---|---|---|

| Conductivité thermique | Élevé (AlN jusqu'à 260 W/m-K) | Modéré (Cu : ~400 W/m-K) | Faible (<1 W/m-K) |

| Isolation électrique | Excellent (>10¹³ Ω-cm) | Pauvre | Bon |

| Résistance à la corrosion | Excellent | Modéré/médiocre | Bon |

| Stabilité à haute température | Excellent (>1000°C) | Bonne (500-800°C) | Médiocre (<200°C) |

| Résistance à l'usure | Excellent | Bon | Pauvre |

Applications clés

Capacités de fabrication de céramiques pour semi-conducteurs

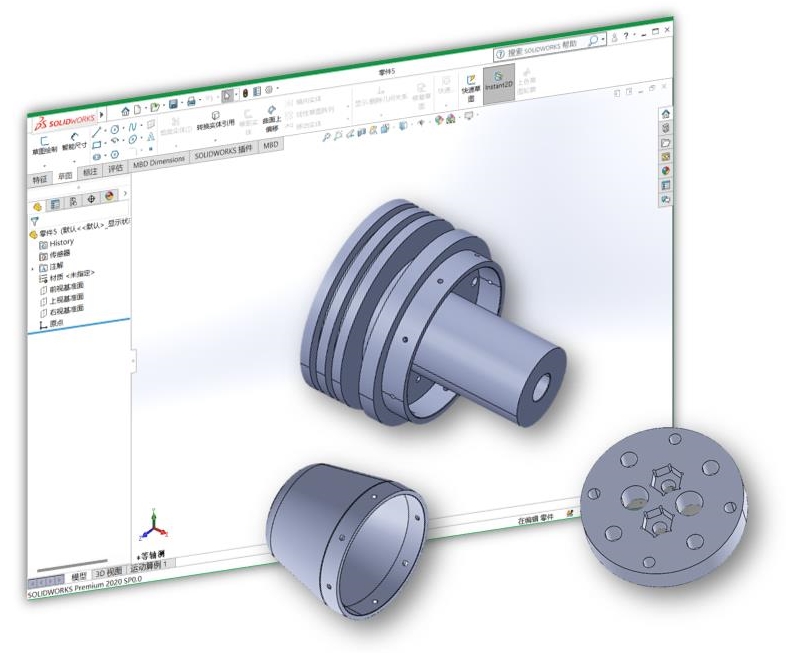

Chez Great Ceramic, nous sommes spécialisés dans les domaines suivants l'usinage sur mesure de composants céramiques avancés. Nos services de fabrication de précision garantissent que chaque pièce répond aux spécifications exactes de la conception, avec des tolérances serrées et des finitions lisses. Nous offrons :

Produits pertinents

Foire aux questions (FAQ)

Votre partenaire de confiance pour les céramiques avancées

Les céramiques avancées redéfinissent les industries des semi-conducteurs et de l'électronique, en permettant une plus grande densité de puissance, une meilleure gestion thermique et une plus longue durée de vie des appareils.

Great Ceramic propose des services d'usinage de précision, de conception personnalisée et de métallisation pour répondre aux exigences de vos applications électroniques, en créant des composants céramiques personnalisés et de haute performance.