Applications des grandes céramiques dans toutes les industries

Les céramiques avancées sont devenues indispensables dans un large éventail d'industries, offrant des solutions inégalées dans des applications à haute performance et à forte demande. Qu'il s'agisse d'alimenter la prochaine génération de composants aérospatiaux, d'améliorer la fiabilité des implants médicaux ou de permettre une électronique à haut rendement, ces matériaux sont au cœur de l'innovation et du progrès industriel.

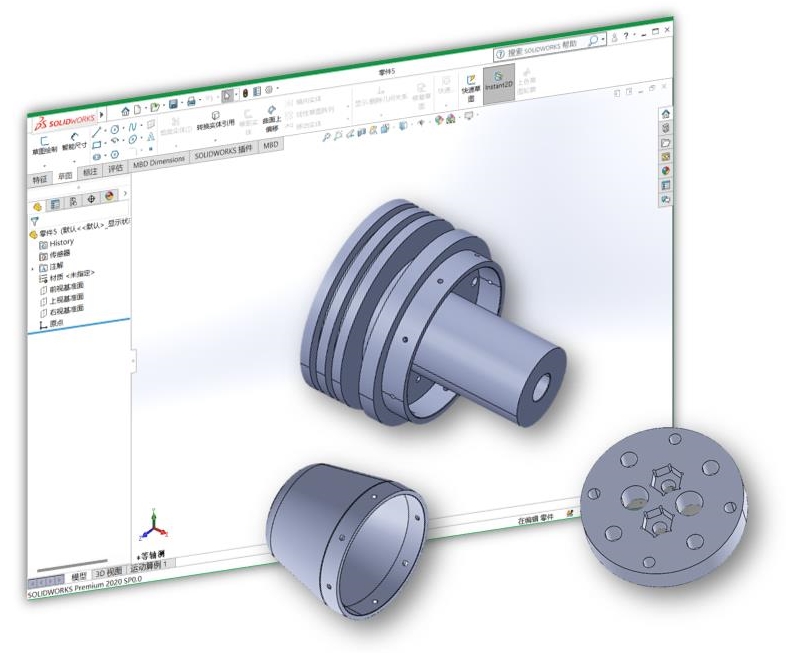

Chez Great Ceramic, nous sommes spécialisés dans la fourniture de pièces et de substrats céramiques de précision qui répondent aux exigences techniques les plus rigoureuses. Notre expertise en matière d'usinage céramique, de métallisation et de services de brasage permet aux entreprises d'améliorer la fiabilité de leurs produits, de réduire les défaillances des systèmes et d'améliorer leur efficacité opérationnelle.

Pourquoi choisir Advanced Ceramics ?

Les matériaux céramiques avancés, avec leur résistance exceptionnelle aux hautes températures, à l'usure, à l'isolation électrique, à la conductivité thermique et à la stabilité chimique, remplacent rapidement les métaux et les polymères traditionnels, devenant des matériaux de base essentiels dans des secteurs haut de gamme tels que l'aérospatiale, les semi-conducteurs, l'électronique, la production d'énergie, l'automobile et la technologie biomédicale.

Des matériaux à la pointe de l'industrie

Great Ceramic fabrique une large gamme de matériaux céramiques avancés afin de s'assurer que nous pouvons produire des produits parfaitement adaptés à votre application. Nos matériaux céramiques avancés (techniques) offrent des performances exceptionnelles, rendant vos produits plus légers, plus efficaces et plus durables, tout en réduisant les coûts de maintenance et d'exploitation à long terme.

| Matériau | Caractéristiques | Points forts | Présentation du produit |

|---|---|---|---|

| Alumine (Al₂O₃) | Résistant à l'usure, isolant | Rectification de précision pour les pièces de haute performance | Télécharger |

| Zircone (ZrO₂) | Résistant, polissable, haute résistance | Idéal pour les composants nécessitant une résistance à la rupture | Télécharger |

| Carbure de silicium (SiC) | Extrêmement dur, chimiquement stable | Excellente dans les environnements corrosifs et à haute température | Télécharger |

| Nitrure de silicium (Si₃N₄) | Léger, résistant aux chocs thermiques, solide à haute température | Convient aux pièces de forme complexe pour l'aérospatiale et les moteurs | Télécharger |

| Nitrure d'aluminium (AlN) | Conductivité thermique élevée, isolation électrique | Nécessite un meulage de précision pour les composants de gestion thermique | Télécharger |

| ZTA (alumine durcie à la zircone) | Amélioration de la ténacité et de la résistance à l'usure | Usinable avec des tolérances serrées pour les pièces structurelles | – |

| Nitrure de bore (BN) | Excellente résistance aux chocs thermiques, isolation électrique, usinable | Facilement façonnable ; idéal pour les pièces non réactives à haute température | Télécharger |

| MGC | Facilement usinable, thermiquement stable | Idéal pour le prototypage rapide et les formes complexes | Télécharger |

Si votre application nécessite des composants céramiques personnalisés, nous vous aiderons à choisir le meilleur matériau et la meilleure stratégie d'usinage.

Foire aux questions (FAQ)

Partenariat avec Great Ceramic

En tant que fabricant de confiance de composants céramiques de précision, Great Ceramic fournit des solutions sur mesure pour répondre aux besoins spécifiques de votre industrie. Nos services comprennent :

Laissez-nous vous aider à intégrer des solutions céramiques avancées dans vos produits.