Silisyum Karbür (SiC) Seramikler

19. yüzyılın sonlarından beri karborundum silisyum karbür seramikler (SiC) olarak bilinen bu silikon ve karbon bileşiği, aşındırıcı tozlardan yüksek performanslı mühendislik için bir köşe taşı malzemesine dönüşmüştür. Günümüzde silisyum karbür seramikler, yarı iletkenler ve elektronikten havacılık, otomotiv, enerji ve kimyasal işlemeye kadar çeşitli sektörlerde vazgeçilmezdir.

Silisyum karbür nedir? Bilimsel anlamda, SiC kimyasal formülüne sahip kovalent bağlı bir silisyum karbür bileşiğidir ve farklı poli tiplerde (3C, 4H, 6H) bulunabilen benzersiz bir kristal yapı sergiler. Yüksek sertliği (Mohs 9.5), düşük yoğunluğu (~3.1 g/cm³), yüksek erime sıcaklığı (~2,700 °C) ve mükemmel silisyum karbür termal iletkenliği, metallerin veya plastiklerin yetersiz kaldığı zorlu uygulamalar için idealdir.

Great Ceramic olarak, eşsiz hassasiyet, tutarlılık ve güvenilirlik sunarak müşteri gereksinimlerine göre tasarlanmış silisyum karbür parçalar sağlıyoruz.

Şuraya atla

Avantajlar | Uygulamalar | Malzeme Sınıfları | Özellikler | Vakalar | Talaşlı İmalat | SSS | İlgili

Silisyum Karbür Seramiklerin Avantajları

Mekanik, termal ve elektriksel özelliklerin benzersiz kombinasyonu SiC'yi teknik seramikler arasında öne çıkarmaktadır.

Mevcut silisyum karbür malzeme kaliteleri

Great Ceramic, her uygulama için optimize edilmiş bir dizi yüksek performanslı silisyum karbür malzeme sunar:

Basınçsız Sinterlenmiş Silisyum Karbür Seramikler(SSIC)

Basınçsız sinterlenmiş silisyum karbür seramikler (SSiC), yüksek sıcaklıkta, basınçsız sinterleme işlemiyle üretilen yüksek performanslı yapısal seramiklerdir. Birincil bileşenleri yüksek saflıkta silisyum karbür tozudur. Sinterleme işlemi sırasında metalik bağlayıcı veya harici basınç gerekmez, bu da son derece yüksek saflık ve yoğunluk ile sonuçlanarak mükemmel genel performans sağlar. Bu malzeme, olağanüstü mekanik mukavemeti, aşınma direnci ve korozyon direnci nedeniyle son derece zorlu ortamlarda yaygın olarak kullanılmaktadır.

Temel Özellikler

Tipik Uygulamalar

Üretim Süreci

Basınçsız sinterlenmiş silisyum karbür seramikler, yüksek saflıkta SiC tozundan yapılır, daha sonra az miktarda sinterleme yardımcısı ile bir kalıp haline getirilir ve 2000 ° C'yi aşan sıcaklıklarda basınçsız olarak sinterlenir. Bu işlem, malzemeye teorik yoğunluğa yakın, ince ve düzgün taneli yoğun bir yapı kazandırır ve böylece mükemmel kapsamlı performans sağlar.

Reaksiyon Sinterlenmiş Silisyum Karbür Seramikler (SISiC)

Reaksiyon-Sinterlenmiş Silisyum Karbür Seramikler (SISiC), silisyum karbür (SiC) tozu ve bir karbon kaynağından yapılan yüksek performanslı bir seramik malzemedir. Sıvı silisyum, yüksek sıcaklıkta yeşil bir gövdeye sızarak yeni silisyum karbür üreten bir reaksiyon oluşturur. Basınçsız sinterlenmiş silisyum karbür (SSiC) ile karşılaştırıldığında, SISiC daha düşük üretim sıcaklıklarına ve daha esnek bir sürece sahiptir ve büyük ölçekli ve karmaşık şekilli yapısal bileşenlerin imalatına olanak tanır. Sonuç olarak, yaygın bir endüstriyel uygulamaya sahiptir.

Temel Özellikler

Tipik Uygulamalar

Üretim Süreci

Reaksiyon sinterlenmiş silisyum karbürün hazırlanma süreci tipik olarak şunları içerir:

Bu yöntemin avantajları arasında basit bir süreç, düşük sinterleme sıcaklığı ve net boyutlara yakın büyük, karmaşık bileşenlerin üretimine olanak tanıyan minimum boyutsal büzülme yer alır. Bununla birlikte, kalıntı silikonun varlığı nedeniyle, yüksek sıcaklık mukavemeti ve oksidasyon direnci SSiC'den biraz daha düşüktür.

Silisyum Karbürün Temel Özellikleri

Great Ceramic, müşterilerin aralarından seçim yapabileceği çeşitli silisyum karbür malzemeler sunmaktadır. Aşağıdaki değerler tipik malzeme özellikleridir ve ürün konfigürasyonuna ve üretim sürecine bağlı olarak değişebilir. Daha fazla ayrıntı için, lütfen çekinmeyin Bize ulaşın.

| Özellikler | Birim | SSiC | SiSiC | Si3N4 |

|---|---|---|---|---|

| Renk | -- | Koyu Gri | Koyu Gri | Gri veya siyah |

| Yoğunluk | g/cm³ | 3.15 | 3.02 | 3.2 |

| Gözeneklilik | % | ≤0.1 | ≤0.1 | -- |

| Sertlik | GPa | 22 | 22 | 15 |

| Basınç Dayanımı | MPa | 2600 | 2600 | 2500 |

| Eğilme Dayanımı | MPa | 400 | 250 | 700 |

| Elastik Modül | GPa | 410 | 330 | 300 |

| Maksimum Kullanım Sıcaklığı | ℃ | 1400 | 1000 | 1100 |

| Termal İletkenlik | W/(m・K) | 100~120 | 45(1200℃) | 15~20 |

| Termal Genleşme Katsayısı | 1 x 10-6/°C | 4 | 4.5 | 3 |

Silisyum Karbür Malzemelerin Kimyasal Özellikleri

Oksijen reaksiyonundaki sıcaklık 1300°C'ye ulaştığında, silisyum karbür kristalinin yüzeyinde koruyucu bir silisyum dioksit tabakası oluşacaktır. Koruyucu tabakanın kalınlaşmasıyla, iç silisyum karbür direnç gösterir ve bağlanmaya devam eder, böylece silisyum karbür kristal silisyum karbür iyi kimyasal dirence sahiptir. Korozyon direnci açısından SiC malzemeler, silikon dioksit koruyucu filmin rolü nedeniyle güçlü asit direncine sahiptir, ancak alkali direnci zayıftır.

Silisyum Karbür Seramik Uygulama Örnekleri

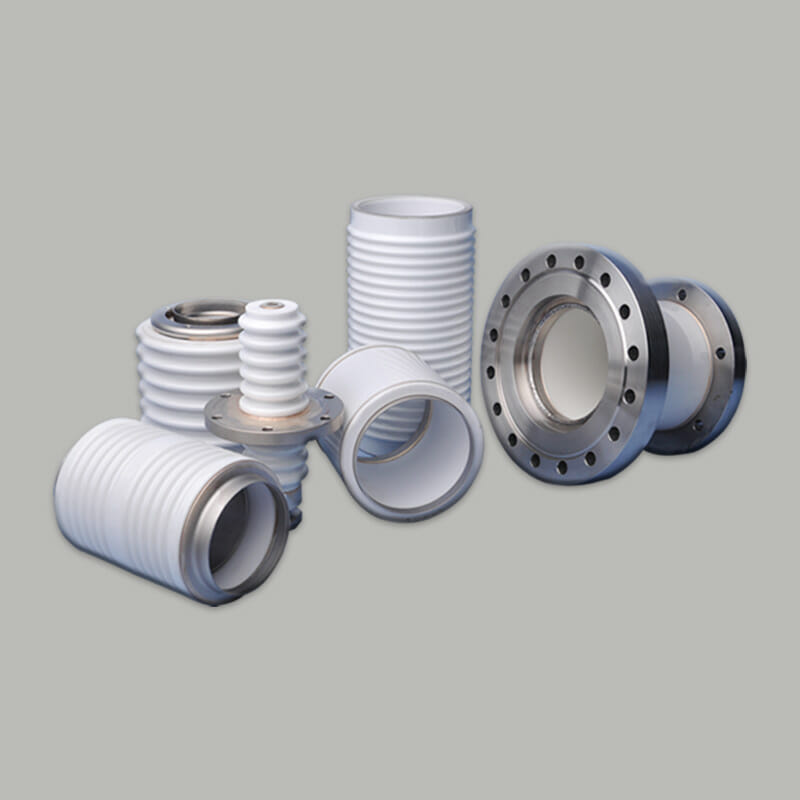

Great Ceramic'in silisyum karbür (SiC) seramikleri olağanüstü sertlik, mükemmel termal iletkenlik, üstün aşınma direnci ve olağanüstü kimyasal stabiliteyi bir araya getirerek onları zorlu endüstriyel uygulamalar için en gelişmiş seramik malzemelerden biri haline getirir. Yüksek erime noktası, düşük termal genleşme ve aşırı ortamlara dayanma kabiliyeti ile silisyum karbür seramikler dayanıklılık, verimlilik ve uzun hizmet ömrü gerektiren endüstriler için idealdir.

Silisyum Karbür Seramiklerin Temel Uygulamaları:

Silisyum Karbür Seramik İşleme

Silisyum karbür (SiC) seramikler aşırı sertlikleri, yüksek termal iletkenlikleri ve mükemmel aşınma dirençleriyle bilinir ve bu da onları işlenmesi en zor teknik seramiklerden biri haline getirir. Great Ceramic olarak, endüstri lideri hassasiyet, performans ve güvenilirlik sağlayan kapsamlı silisyum karbür işleme hizmetleri sunuyoruz.

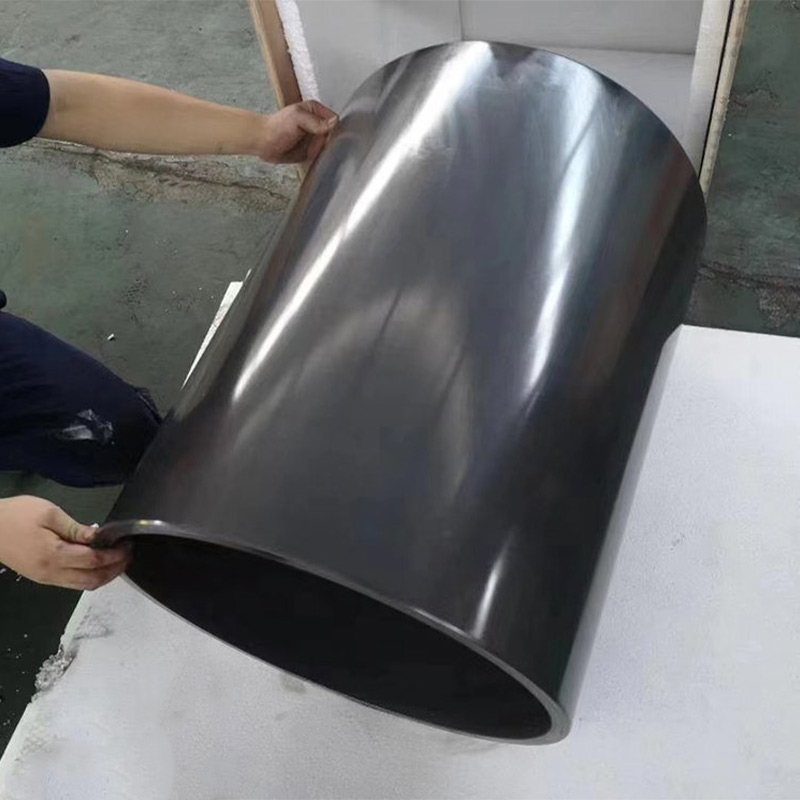

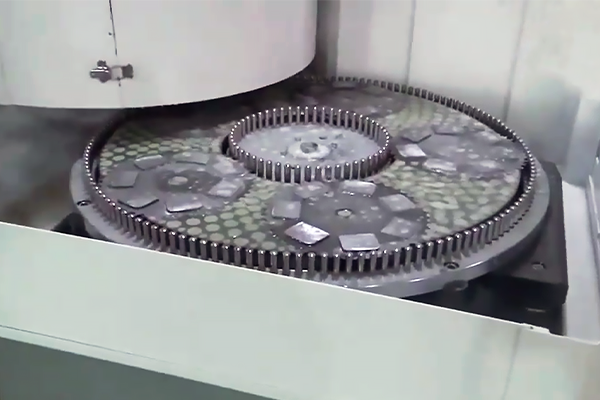

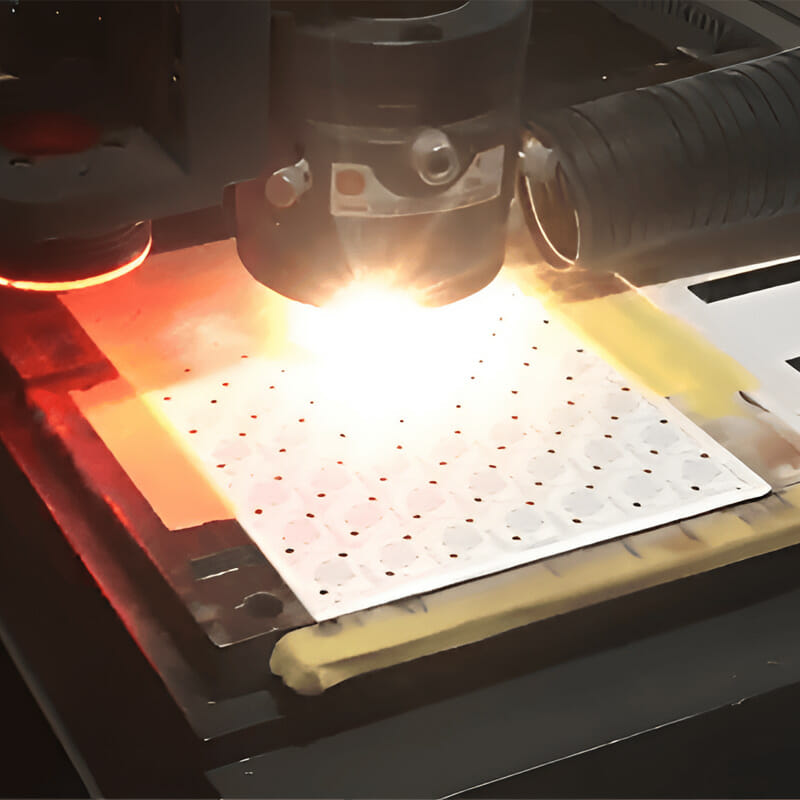

İşleme sırasında, mikron düzeyinde toleranslar ve olağanüstü yüzey kalitesi elde etmek için gelişmiş elmas taşlama, hassas lepleme ve ince parlatma teknikleri kullanıyoruz. Bu yetenekler, mekanik contaların, yarı iletken alt tabakaların, potaların, ısı eşanjörlerinin ve havacılık bileşenlerinin katı yapısal doğruluk ve yüzey kalitesi gereksinimlerini karşılamamızı sağlar.

Yıllara dayanan teknik uzmanlığı ve son teknoloji ekipmanlarıyla Great Ceramic, yalnızca standartlaştırılmış silisyum karbür parçalar tedarik etmekle kalmaz, aynı zamanda belirli endüstriyel ihtiyaçlara göre özelleştirilmiş karmaşık bileşenler geliştirerek zorlu çalışma koşullarında yüksek güvenilirlik ve uzun hizmet ömrü sağlar.

Sıkça Sorulan Sorular

İlgili ürünler

Silisyum Karbür Seramikler için Neden Bizi Seçmelisiniz?

At Harika SeramikBiz bir silisyum karbür seramik tedarikçisinden daha fazlasıyız - hassas bir mühendislik ortağıyız. Güçlü yönlerimiz şunları içerir: