Keramische Metallisierung & Metalllötlösung

Unter Große Keramikbieten wir Professionelle Metallisierung von Keramikoberflächen und Lötarbeiten für anspruchsvolle Branchen wie Luft- und Raumfahrt, Leistungselektronik, Vakuumsysteme, medizinische Geräte und Halbleiterherstellung.

Die Kombination von fundiertem Fachwissen in technische Keramiken, Präzisionshartlötenund hermetische Keramik-Metall-Dichtunghelfen wir unseren Kunden, zuverlässige und leistungsstarke Baugruppen zu entwickeln, die auch unter extremen Bedingungen funktionieren.

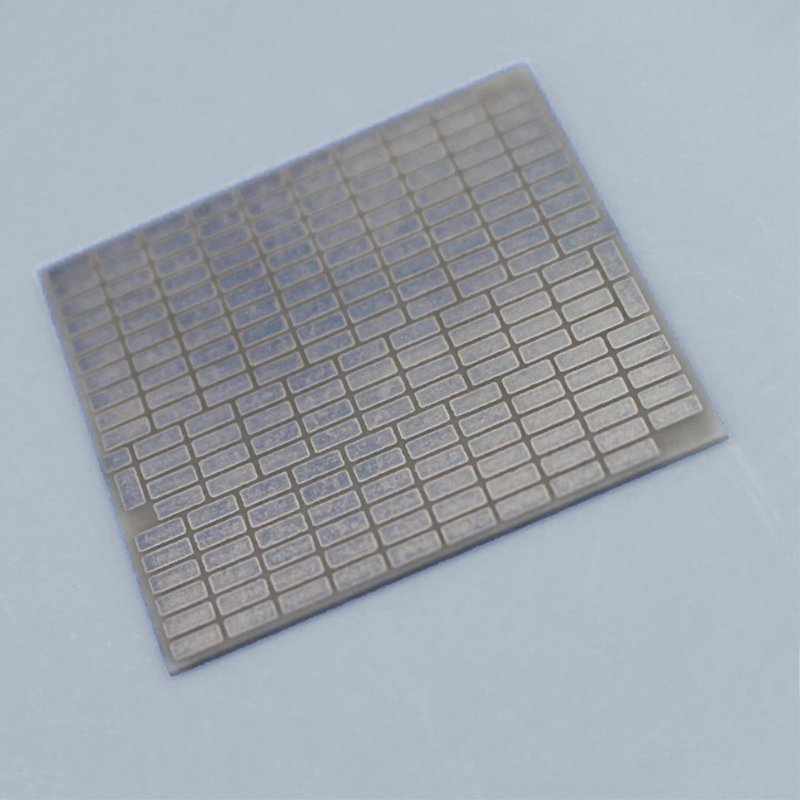

Keramische Metallisierung ist das Aufbringen einer leitfähigen Metallschicht auf die Oberfläche keramischer Bauteile, so dass diese gelötet oder elektrisch mit Metallen verbunden werden können. Dieses Verfahren ist wichtig für die Herstellung von Keramik-Metall-Dichtungen in Vakuumsystemen, Hochfrequenzgeräten und elektrischen Isolationsbaugruppen.

Bei Great Ceramic bieten wir mehrere Metallisierungsoptionen an:

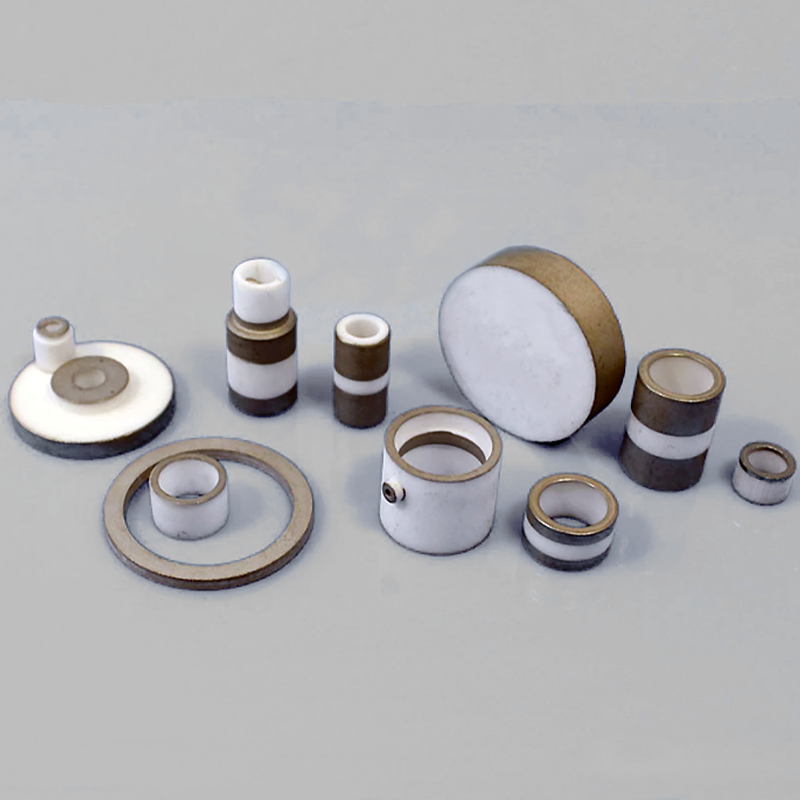

Metallisierte keramische Komponenten, die wir anbieten

Metallisierter keramischer Isolator

Geeignet für RF-Fenster, Lasersysteme und Sensorgehäuse

Vakuum-Keramik-Komponente

Maßgeschneidert für spezifische mechanische, elektrische oder umwelttechnische Anforderungen

Metallisierte keramische Rohre

Verwendung in Elektronenröhren, Thermoelementen und Isolierungen

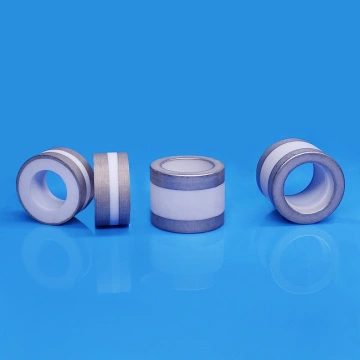

Metallisierter keramischer Ring

Hermetische Durchführungen für Vakuum- und Leistungsgeräte

Alle metallisierten Schichten werden auf Haftung, Dicke, Kontinuität und Oberflächenqualität geprüft. Galvanisierte Schichten werden auf Lötbarkeit und Korrosionsbeständigkeit geprüft.

Nach der Metallisierung werden die keramischen Teile mit Hilfe von Hochtemperaturlöttechniken auf Metalle wie Kovar, Titan oder Edelstahl gelötet. So entstehen Keramik-Metall-Bauteile mit hervorragender Gasdichtigkeit und mechanischer Zuverlässigkeit.

Great Ceramic ist in der Lage, technische keramisch gelötete Komponenten zu liefern, die den spezifischen Anforderungen der Kunden entsprechen. Viele der von uns gelieferten Teile sind komplex, nach strengen Spezifikationen entworfen oder werden in besonders anspruchsvollen kritischen Anwendungen eingesetzt.

Merkmale des keramischen Lötens

Das Produkt verwendet Kovar-Material oder sauerstofffreies Kupfer mit einem linearen Ausdehnungskoeffizienten, der dem von Keramik ähnlich ist, um eine Keramik-Metall-Dichtung durch Löten zu erreichen. Ermöglicht die luftdichte Verbindung von keramischen Teilen und Metallbauteilen. Diese Keramik-Metall-Dichtungsstruktur zeichnet sich durch eine hohe Dichtungsstärke, gute Luftdichtheit und hohe Zuverlässigkeit aus.

Anwendungen für keramisches Löten und Versiegeln

Verwendet in Vakuumschaltröhren für elektrische Energie und Elektronik, verschiedenen Klystrons, Wanderfeldröhren, Mikrowellenröhren, Magnetrons, Thyratrons, Triggern, Vakuummessgeräten, Mikrowellennachtsichtgeräten und anderen verwandten Bereichen der Vakuumisolierung. Die allgemeine Verwendungstemperatur übersteigt nicht 700°C.

Anwendungen von metallisierten Keramiken und gelöteten Baugruppen

Unser metallisierte Keramiken und gelötete Komponenten werden in vielen Branchen für kritische Aufgaben eingesetzt, die eine Hermetische Dichtigkeit, elektrische Isolierung, Wärmeleitfähigkeitund mechanische Festigkeit.