Yarı İletken ve Elektronik Sektöründe İleri Seramik Uygulamaları

Yarı iletken ve elektronik bileşenler endüstrisi, yüksek sıcaklıklar, hızlı termal döngü, yüksek voltajlar ve ultra temiz üretim ortamları gibi aşırı koşullar altında güvenilir bir şekilde çalışabilen malzemeler talep etmektedir. Gelişmiş seramikler mekanik mukavemet, elektrik yalıtımı, termal stabilite ve kimyasal inertliğin olağanüstü kombinasyonu nedeniyle bu alanda vazgeçilmez hale gelmiştir. Aşağıdakiler gibi malzemeler alümina (Al₂O₃), alüminyum nitrür (AlN), silisyum nitrür (Si₃N₄), zirkonya (ZrO₂), berilyum oksit (BeO)ve bor nitrür (BN) yarı iletken işleme ekipmanlarında, mikroelektronik ambalajlarda ve yüksek performanslı elektronik cihazlarda yaygın olarak kullanılmaktadır.

Yarı İletken ve Elektronik Uygulamaları için Gelişmiş Seramiklerin Temel Avantajları

fayda:

Yarı İletken ve Elektronik Uygulamalarında Anahtar Malzemeler

Great Ceramic olarak, yarı iletken ve elektronik endüstrilerinde yüksek performanslı seramiklerin uygulanmasını geliştirmeye ve müşterilerimizin benzeri görülmemiş performans, güvenilirlik ve sürdürülebilirlik seviyelerine ulaşmalarına yardımcı olmaya kararlıyız.

| Malzeme | Temel Özellikler | Tipik Uygulamalar |

|---|---|---|

| Alümina (Al₂O₃) | Uygun maliyetli, iyi yalıtım, orta düzeyde ısı iletkenliği | LED substratlar, çok katmanlı paketler, seramik PCB'ler |

| Alüminyum Nitrür (AlN) | Yüksek ısı iletkenliği, elektrik yalıtımı, Si ile CTE uyumu | Güç modülü alt tabakaları, RF cihaz ısı dağıtıcıları |

| Silisyum Nitrür (Si₃N₄) | Yüksek kırılma tokluğu, termal şok direnci | Wafer taşıma kolları, güç elektroniği alt tabakaları |

| Silisyum Karbür (SiC) | Yüksek mukavemet, korozyon direnci, termal stabilite | CVD odası bileşenleri, difüzyon fırını gömlekleri |

| Bor Nitrür (BN) | Isı iletkeni + elektrik yalıtkanı, işlenebilir | RF/mikrodalga cihazlar için ısı alıcıları, arayüz katmanları |

| İşlenebilir Cam Seramikler (MGC) | Kolay hassas işleme, 1000°C'ye kadar stabil | Prototipleme parçaları, küçük parti hassas bileşenler |

| ZTA (Zirkonya Sertleştirilmiş Alümina) | Yüksek aşınma direnci, geliştirilmiş kırılma tokluğu | Hassas kılavuzlar, yarı iletken taşıma araçları |

Metal ve Plastiklere Göre Performans Avantajları

| Mülkiyet | İleri Seramik | Metaller | Plastikler |

|---|---|---|---|

| Termal İletkenlik | Yüksek (260 W/m-K'ye kadar AlN) | Orta (Cu: ~400 W/m-K) | Düşük (<1 W/m-K) |

| Elektrik İzolasyonu | Mükemmel (>10¹³ Ω-cm) | Zayıf | İyi |

| Korozyon Direnci | Mükemmel | Orta/Zayıf | İyi |

| Yüksek Sıcaklık Kararlılığı | Mükemmel (>1000°C) | İyi (500-800°C) | Zayıf (<200°C) |

| Aşınma Direnci | Mükemmel | İyi | Zayıf |

Anahtar Uygulamalar

Yarı İletken Sınıfı Seramikler için Üretim Kabiliyetleri

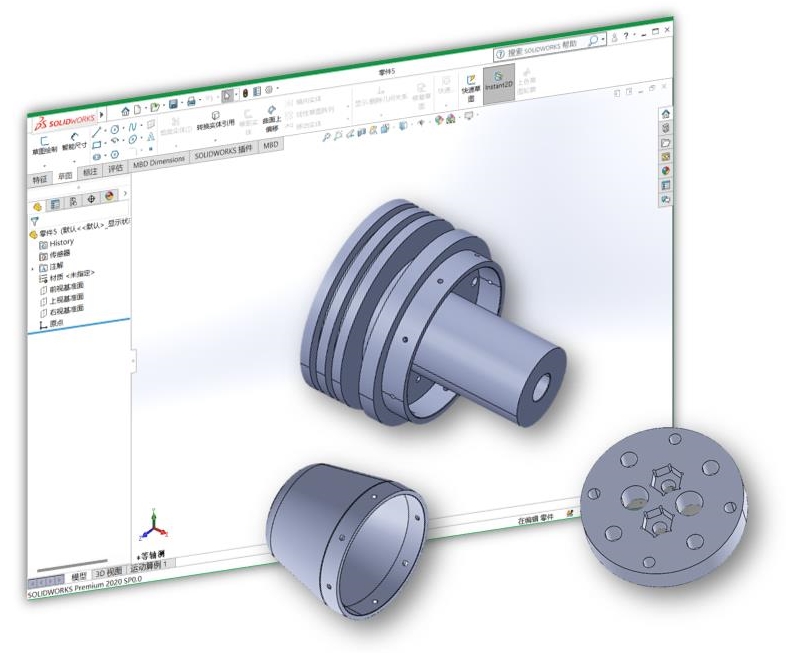

Great Ceramic'te uzmanlık alanımız geli̇şmi̇ş serami̇k bi̇leşenleri̇n özel i̇şlenmesi̇. Hassas üretim hizmetlerimiz, her bir parçanın sıkı toleranslar ve pürüzsüz yüzeyler ile tam tasarım özelliklerini karşılamasını sağlar. Biz teklif ediyoruz:

İlgili Ürünler

Sıkça Sorulan Sorular (SSS)

Gelişmiş seramikler için güvenilir ortağınız

Gelişmiş seramikler, daha yüksek güç yoğunluğu, gelişmiş termal yönetim ve daha uzun cihaz ömrü sağlayarak yarı iletken ve elektronik endüstrilerini yeniden tanımlıyor.

Great Ceramic, elektronik uygulamalarınızın zorlu gereksinimlerini karşılamak için hassas işleme, özel tasarım ve metalizasyon hizmetleri sunarak özel, yüksek performanslı seramik bileşenler oluşturur.