Petrol ve Gaz Endüstrisinde İleri Seramik Uygulamaları

Petrol ve gaz endüstrisinde, aşırı sıcaklıklar, yüksek basınçlar, aşındırıcı kimyasallar ve aşındırıcı koşullar içeren operasyonel ortamlar dünyanın en zorlu ortamları arasındadır. Geleneksel metaller ve polimerler genellikle zaman içinde performansı korumakta zorlanır ve bu da maliyetli duruş sürelerine ve bakıma yol açar. İşte bu noktada i̇leri̇ serami̇kler dönüştürücü bir çözüm sunar.

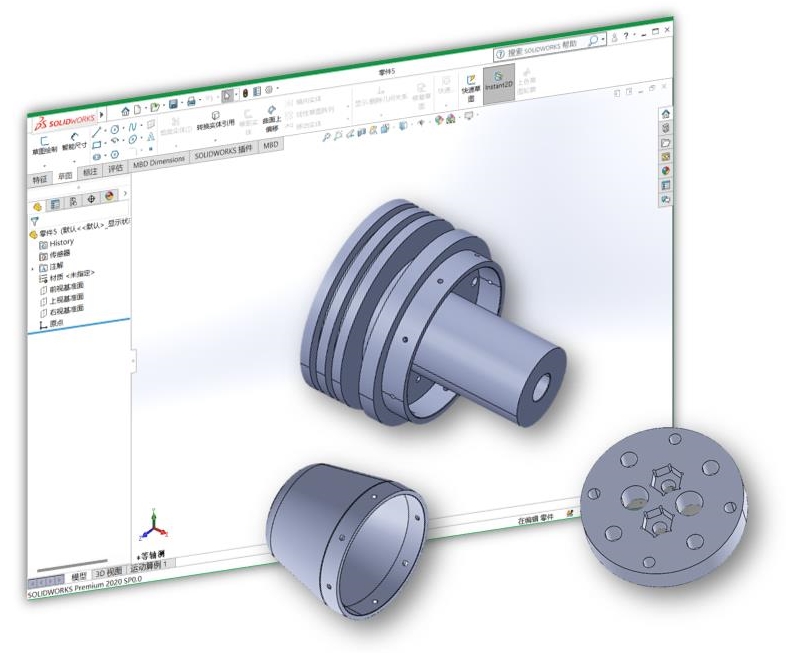

At Harika Seramikiçin özel olarak tasarlanmış hassas mühendislik ürünü seramik bileşenler sağlıyoruz. petrol ve gaz endüstrisigibi malzemelerin benzersiz özelliklerinden yararlanarak alümina (Al₂O₃), zirkonya (ZrO₂), silisyum karbür (SiC), silisyum nitrür (Si₃N₄)ve bor nitrür (BN). Bu teknik seramikler benzersiz aşınma direnci, termal kararlılık, kimyasal inertlikve elektri̇k yalitimiBu da onları yukarı akış, orta akış ve aşağı akış uygulamaları için gerekli kılmaktadır.

Neden Petrol ve Gaz için Gelişmiş Seramikler?

Gelişmiş seramikler, mekanik mukavemet, kimyasal dayanıklılık ve termal esnekliğin güçlü bir kombinasyonunu sunarak modern petrol ve gaz operasyonlarının vazgeçilmezi haline gelmiştir. İster sondajda, ister üretimde veya keşifte olsun, seramikler bakımı azaltmaya, güvenliği artırmaya ve hizmet ömrünü uzatmaya yardımcı olarak uygun maliyetli ve güvenilir enerji çözümlerini destekler.

Bu özellikler, seramiklerin kritik petrol ve gaz bileşenlerinde metal ve polimerlerden daha iyi performans göstermesini sağlar.

fayda:

Petrol ve Gaz Alanında İleri Seramiklerin Temel Uygulamaları

Petrol ve Gaz Endüstrisi için Tipik Seramik Bileşenler

Great Ceramic olarak kendimizi petrol ve gaz mühendisliğinde yüksek performanslı seramiklerin kullanımını geliştirmeye adadık. Aşağıdaki malzemelerden yapılmış özel bileşenler sağlıyoruz:

| Seramik Malzeme | Petrol ve Gaz Uygulaması | Anahtar Özellikler |

|---|---|---|

| Alümina (Al₂O₃) | Valf bileşenleri, elektrik izolatörleri, aşınma manşonları | Mükemmel aşınma direnci, kimyasal stabilite, yüksek elektrik yalıtımı |

| Silisyum Karbür (SiC) | Valf yuvaları, nozullar, çamur pompası gömlekleri, kum kontrol elekleri | Olağanüstü sertlik, yüksek aşınma ve korozyon direnci, termal iletkenlik |

| Zirkonya (ZrO₂) | Yüksek basınç contaları, pistonlar, paketleyici bileşenleri | Yüksek kırılma tokluğu, kimyasal direnç, ısı yalıtımı |

| Silisyum Nitrür (Si₃N₄) | Kuyu içi aletler için rulmanlar, türbin akış kontrol parçaları | Yüksek mukavemet, mükemmel aşınma ve termal şok direnci |

| Alüminyum Nitrür (AlN) | Kuyu içi elektroniği için alt tabakalar, sensör muhafazaları | Mükemmel ısı dağılımı, dielektrik dayanımı, termal şok direnci |

| MGC (İşlenebilir Cam Seramik) | Hassas izolatörler, sensör tabanları, geçişler | Kolayca işlenebilir, boyutsal kararlılık, dielektrik yalıtım |

| Bor Nitrür (BN) | Kayıt araçları için elektrik izolatörleri, termal bariyerler | Yüksek termal kararlılık, elektrik yalıtımı, kimyasal inertlik |

| Berilyum Oksit (BeO) | Mikrodalga iletişim bileşenleri, yüksek frekanslı cihazlar | Çok yüksek ısı iletkenliği, elektrik yalıtımı |

Great Ceramic'in Yetenekleri

Harika Seramik güvenilir bir sağlayıcıdır hassas serami̇k i̇şleme çözümleri̇ ve özelleştirilmiş gelişmiş seramik parçalar Petrol ve Gaz endüstrisinin ihtiyaçlarına göre uyarlanmıştır. Biz teklif ediyoruz:

Petrol ve Gaz ile İlgili Ürünler

Sıkça Sorulan Sorular (SSS)

Petrol ve Gaz Uygulamaları için Neden Great Ceramic'i Seçmelisiniz?

Bizim keşfedin Hassas Seramik İşleme Yüksek performanslı petrol ve gaz bileşenleri için çözümler.