Kimya, Plastik ve Kauçuk Sektörlerinde İleri Seramik Uygulamaları

İleri seramikler, dünya genelinde vazgeçilmez malzemeler olarak ortaya çıkmıştır. kimyasal, plastiklerve kauçuk sektörler, olağanüstü performansları sayesinde korozyon di̇renci̇, aşınma direncive yüksek sıcaklık kararlılığı. itibaren reaktör astarları petrokimya tesislerinde seramik kaplı silindirler Polimer işleme hatlarında, bu tasarlanmış malzemeler ekipman ömrünü optimize eder, proses verimliliğini artırır ve yeşil üretim.

Great Ceramic, kimya, plastik ve kauçuk endüstrileri için özel olarak tasarlanmış hassas mühendislik ürünü seramik bileşenler sağlar. Bu teknik seramikler eşsiz aşınma direnci, termal stabilite, kimyasal inertlik ve elektrik yalıtımı sunarak onları yukarı akış, orta akış ve aşağı akış uygulamaları için gerekli kılar.

Neden Gelişmiş Seramikler Kullanılmalı?

Gelişmiş seramikler, yüksek saflık, kontrollü mikro yapılar ve geleneksel seramiklere kıyasla üstün özelliklerle karakterize edilen mühendislik malzemeleridir. Temel özellikleri şunlardır:

Bu özellikler, gelişmiş seramikleri metallerin veya polimerlerin başarısız olduğu rollerde, özellikle de aşındırıcı, aşındırıcı veya yüksek sıcaklıklı ortamlarda vazgeçilmez kılmaktadır.

fayda:

Anahtar Uygulamalar

Kimya Endüstrisinde

Plastik Sektöründe

Kauçuk Endüstrisinde

En Yaygın Kullanılan Seramik Malzemeler

Great Ceramic olarak, alümina (Al₂O₃), silisyum karbür (SiC), silisyum nitrür (Si₃N₄) ve zirkonyum oksitle sertleştirilmiş alümina (ZTA20) gibi gelişmiş seramikler kullanarak kimya, plastik ve kauçuk endüstrilerindeki müşterilerimizin benzeri görülmemiş performans, güvenilirlik ve sürdürülebilirlik seviyelerine ulaşmalarına yardımcı oluyoruz.

| Seramik Malzeme | Özellikler & Faydalar | Tipik Uygulamalar |

|---|---|---|

| Alümina (Al₂O₃) | Yüksek sertlik, iyi kimyasal direnç, uygun maliyetli | Contalar, burçlar, kılavuzlar, valfler |

| Zirkonya (ZrO₂) | Sert, aşınmaya dayanıklı, korozyona dayanıklı | Pompa milleri, pistonlar, öğütme medyası |

| Silisyum Karbür (SiC) | Aşırı sertlik, termal şok direnci, mükemmel korozyon direnci | Nozullar, reaktör astarları, ekstrüzyon aletleri |

| Silisyum Nitrür (Si₃N₄) | Hafif, yüksek mukavemetli, termal şok direnci | Rulmanlar, karıştırıcılar, yüksek sıcaklık valf bileşenleri |

| Alüminyum Nitrür (AlN) | Yüksek ısı iletkenliği, elektrik yalıtımı | Yüksek sıcaklık elektroniği, ısıtıcılar, proses izleme cihazları |

| Bor Nitrür (BN) | Kimyasal olarak inert, mükemmel kayganlık ve yalıtım | Yağlama kaplamaları, izolatörler, potalar |

| ZTA (Zirkonya Sertleştirilmiş Alümina) | Dengeli tokluk ve sertlik | Kalıp uçları, kılavuzlar, aşınma plakaları |

| MGC (İşlenebilir Cam Seramik) | Kolayca işlenebilir, iyi ısı/elektrik yalıtımı | Yalıtım bileşenleri, ara parçalar, özel laboratuvar parçaları |

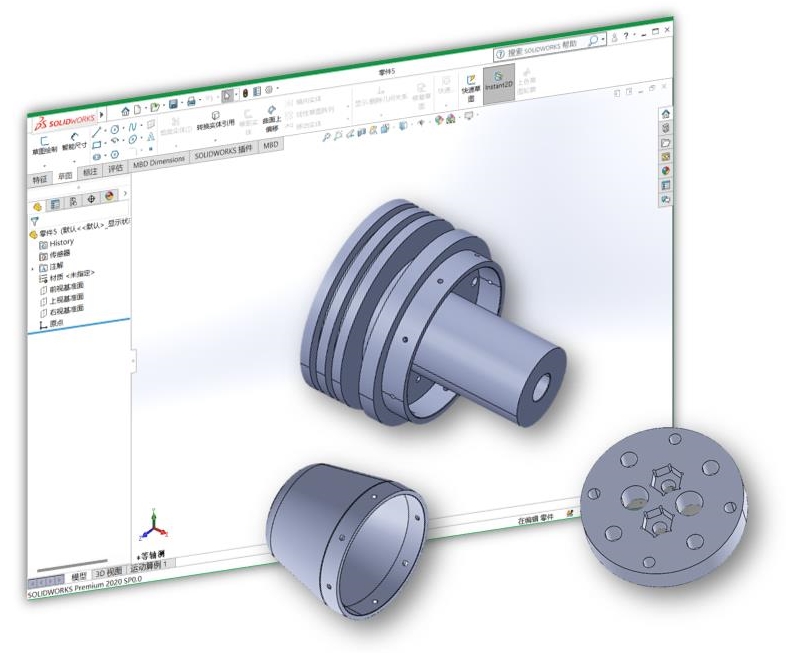

Great Ceramic'in Yetenekleri

Great Ceramic olarak, zorlu kimyasal ve plastik işleme ortamları için özel olarak tasarlanmış hassas seramik parçalar sunuyoruz. Zirkonya pistonlardan alümina nozullara ve silikon karbür aşınmaya dayanıklı astarlara kadar, malzemelerimiz ve üretim kapasitemiz uzun ömürlülük, hassasiyet ve performans sağlar.

İlgili Ürünler

Sıkça Sorulan Sorular (SSS)

Uygulamalar için Neden Great Ceramic'i Seçmelisiniz?

Bizim keşfedin Hassas Seramik İşleme Yüksek performanslı kimyasal, plastik ve kauçuk bileşenler için çözümler.